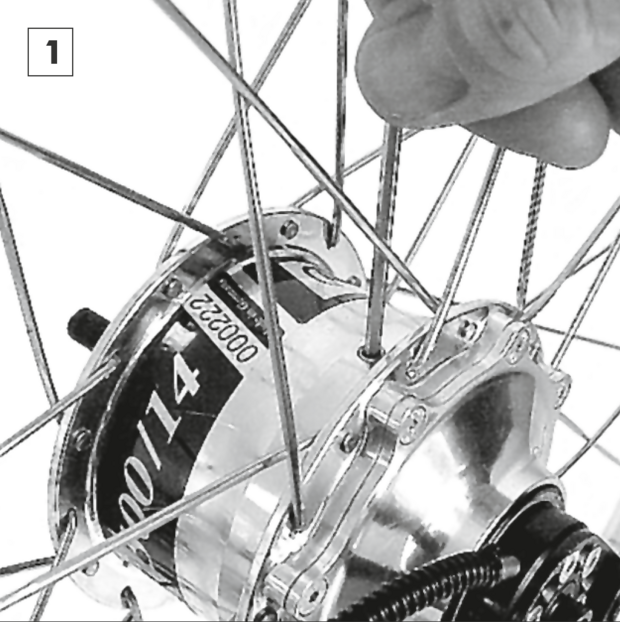

Failure Diagnosis and First Aid

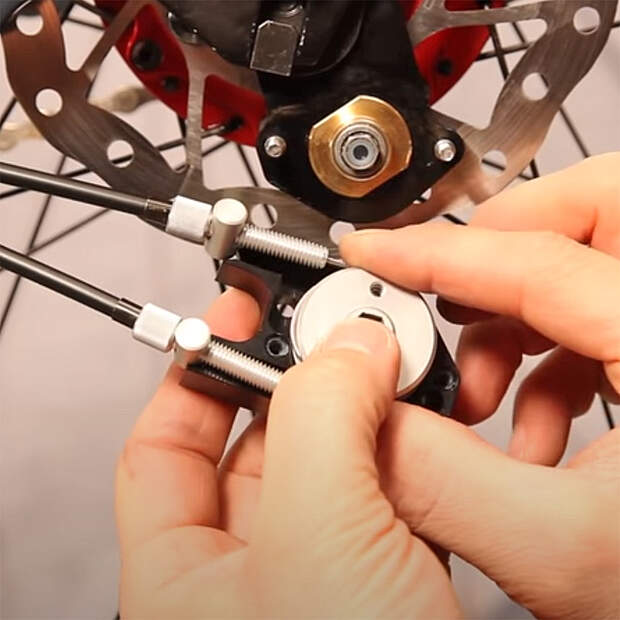

Component Replacement

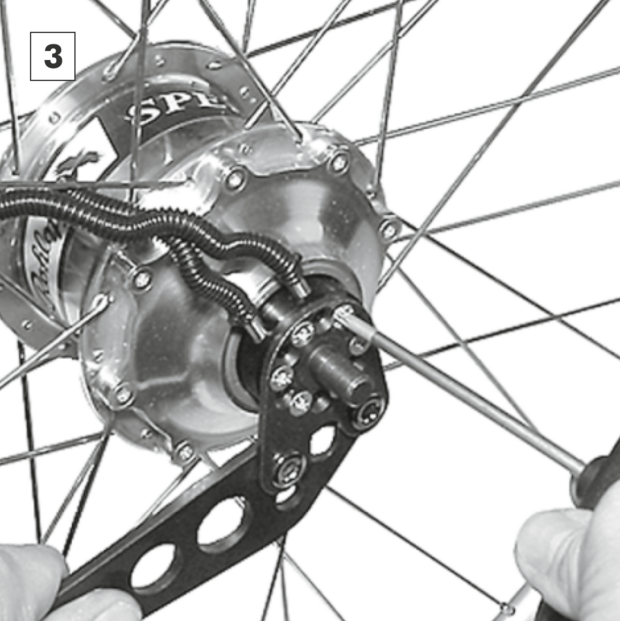

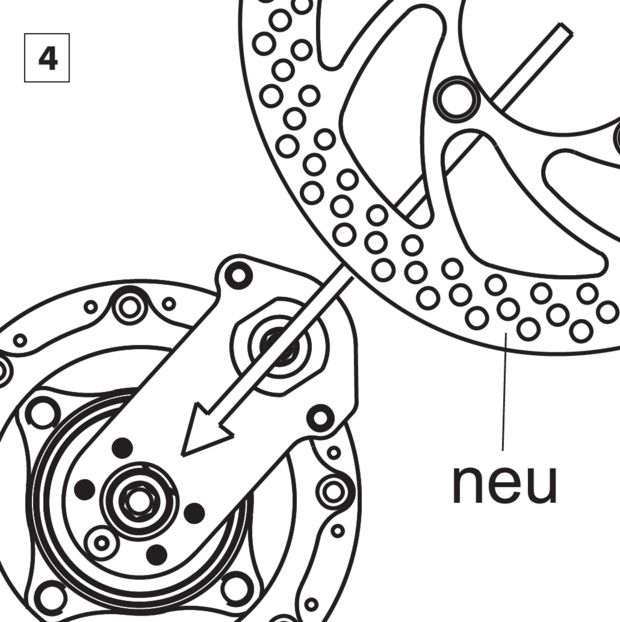

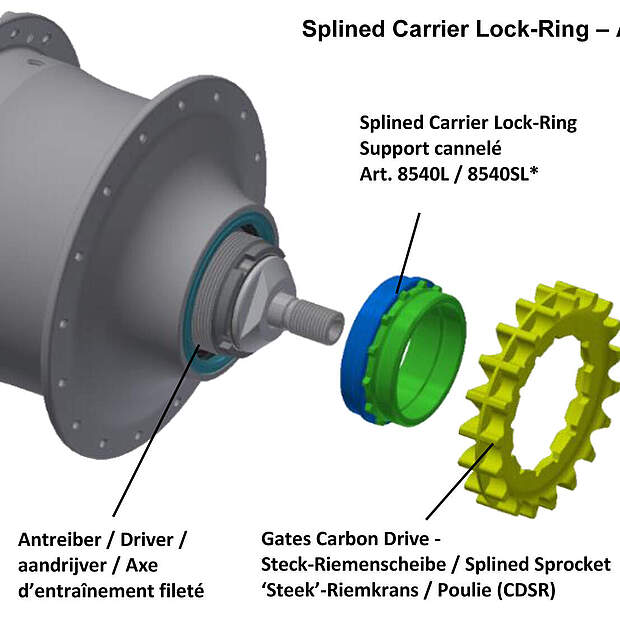

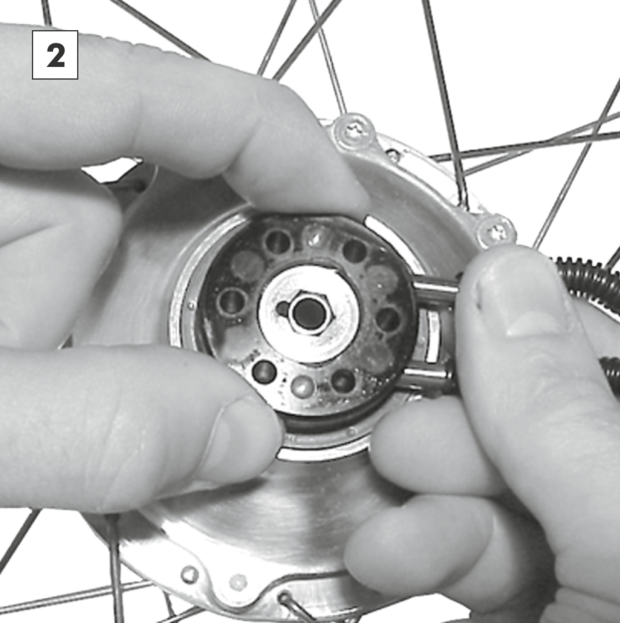

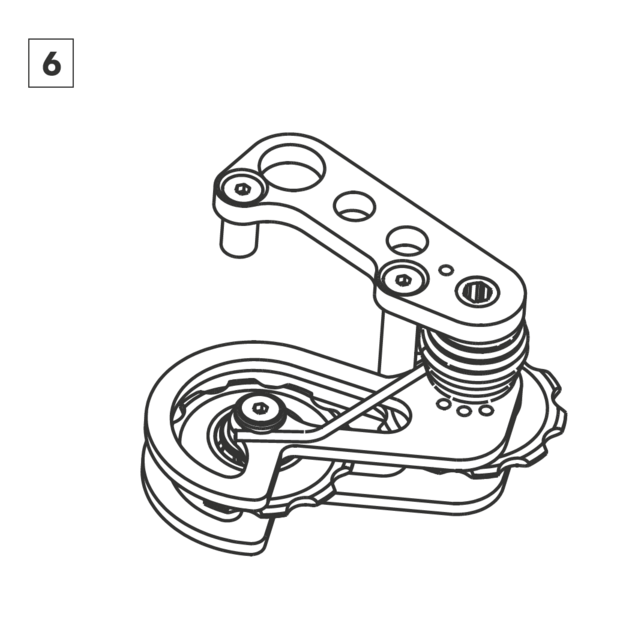

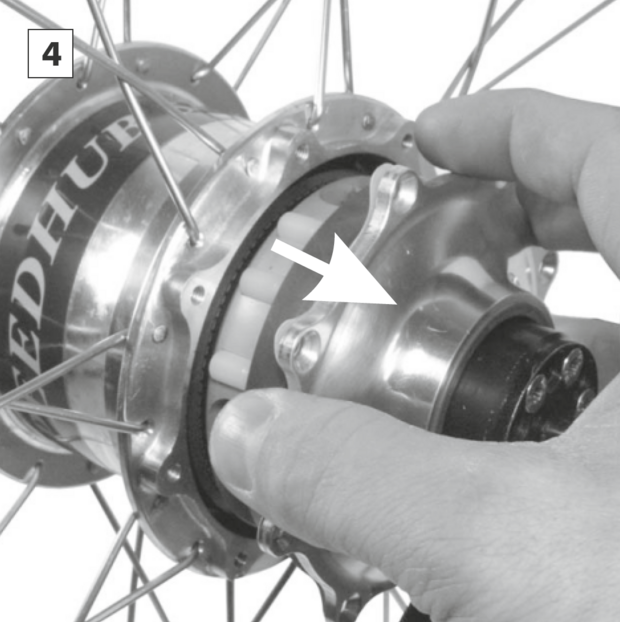

Sprocket Reversing / Replacing

Oil Change

An oil change must be completed every 5000 km or once per Annum to ensure the 25 ml quantity of oil is retained and is free from dirt/moisture contamination. This process ensures that the SPEEDHUB 500/14 will always contain enough oil for lubrication (regardless of oil lost due to sweat oil) and also ensures that any penetrated moisture is rinsed out.