Mounting Check

Modern dropouts are constructed with very few standardized dimensions. The result thereof is unfortunately a complex number of steps that must be undertaken in order to safely mount an A12 SPEEDHUB model.

The axle type as well as the dropouts of each individual frame must be painstakingly checked with precision in order to calculate the quantity and type of mounting hardware required to safely integrate an A12 SPEEDHUB model into the frame.

The qualified bicycle workshop then orders the SPEEDHUB A12 with the necessary parts and assembles everything in the frame.

Pre-check O.L.D.

The A12 SPEEDHUB models are available only as disc brake versions with an O.L.D. of 142mm, 148mm, 177mm and 197mm. The first check therefore, should always be to identify which spacing your frame uses and thus which O.L.D. is required. We are unable to supply an A12 SPEEDHUB unit for any alternative frame spacings.

Overview of O.L.D.s + Delivery Types

Currently untested in tandems and thus unauthorized for tandem application use.

142/148mm

32 or 36 spoke

Silver, red or black anodized finish

Article code is determined via the torque anchoring system. Either:

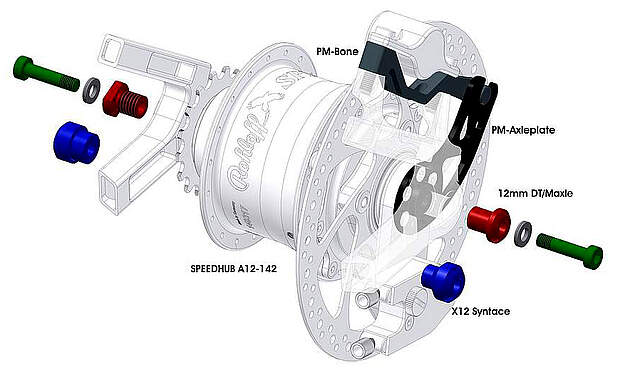

- via the International Standard (IS2000) disc brake mount using a Speedbone or Monkeybone 160/180: A12 DB OEM2

- via the Postmount disc brake mount using a PM Bone: A12 DB PM

The PM Bone simultaneously functions as an adapter from 160-180mm or 180-203mm. The next largest brake rotor must therefore always be used.

177mm

32 spoke only

Black anodized finish only

Article code is determined via the torque anchoring system. Either:

- via the International Standard (IS2000) disc brake mount using a Speedbone or Monkeybone 160/180: A12 DB OEM2 XL

- via the Postmount disc brake mount using a PM Bone: A12 DB PM XL

The PM Bone simultaneously functions as an adapter from 160-180mm or 180-203mm. The next largest brake rotor must therefore always be used.

197mm

32 spoke only

Black anodized finish only: A12 DB OEM2 XXL

Article code is determined via the torque anchoring system. Either:

- via the International Standard (IS2000) disc brake mount using a Monkeybone-10 160/180

- via the Postmount disc brake mount

using a Fatbone 180 (for frames with a 160mm brake rotor) or

using a Fatbone 203 (for frames with a 180mm brake rotor)

The Fatbone simultaneously functions as an adapter from 160-180mm or 180-203mm. The next largest brake rotor must therefore always be used.

Dropout Measurement Kit

A special dropout measurement kit will be required to check frame comaptibility. This will be made available on loan to your local bicycle workshop, via the Rohloff distributor/Service Partner in your country.

In rare circumstances, upon review of the test results, we may ask that one or both sides be re-checked. As such, we advise that the kit is retained by your local bicycle workshop, until we confirm that your frame is compatible/incompatible. This avoids the risk that the kit will need to be shipped out again.

The process for obtaining the kit can vary in different countries. Ask your bicycle workshop to simply get in touch with the local Rohloff distributor/Service Partner for exact details.

Axleplate Selection

Once you have received the measurement kit:

All test results are to be entered in the A12 online form that accompanies you during the fitment test. It is best to leave the form open during the process. So you can enter the results of each measurement, as you go along.

Start by completing the dealer and bicycle frame information sections. This information is vital in order to complete a databank that may possibly eliminate the necessity of this test procedure for future sales.

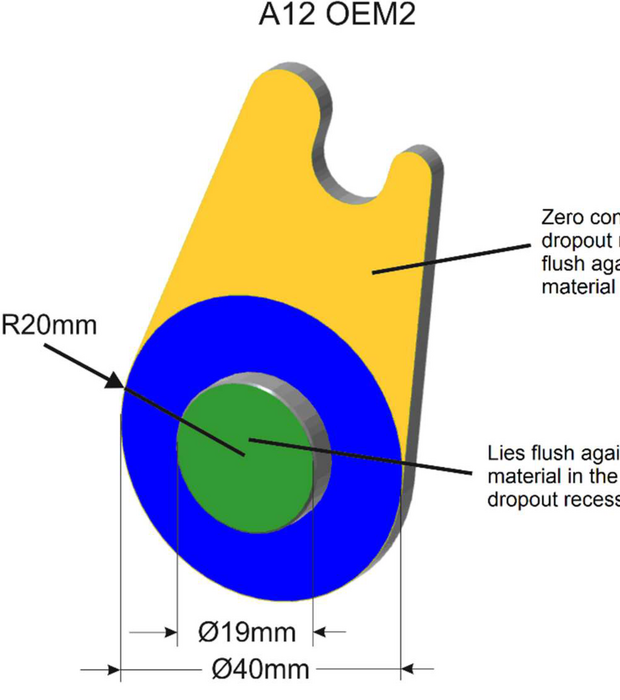

Now you can continue to check which axleplate is required to anchor the hub torque. It is important to check whether the axleplate in the final assembly position lies flush against the dropout material. The online form will help you select the correct parts from the measurement kit.

Fitment Test

If it is clear that the axleplate, when paired with the correct torque support adapter (if applicable) lies flush against the inside surface of the disc brake side dropout, then the actual fitment test can begin.

The test actually consists of two parts: first, reduction sleeves are used to check whether the frame is compatible with the A12 thru axle system, and second, a precise measurement is carried out with a Vernier Caliper.

How exactly the fitment test is to be carried out is described on the dropout compatibility test page. The results of the test are again to be entered in the online form.