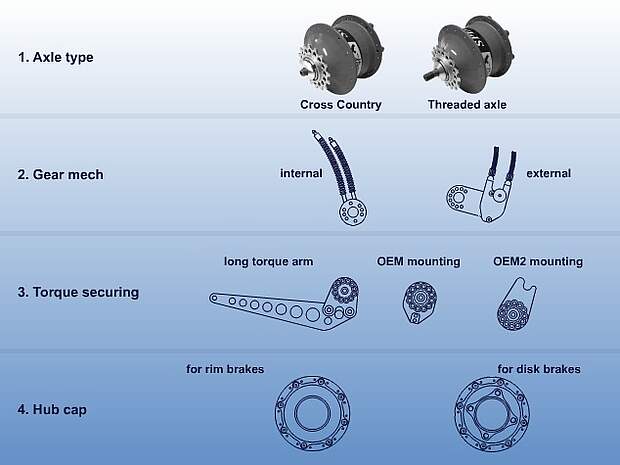

Modular parts system

The various Rohloff SPEEDHUB 500/14 models are based upon a modular system.

There are three axle types (Quick release CC, threaded axles TS and an A12 axle is constructed for frames fitted with dropouts which accept 12 thru-axle systems) presenting a base for the 14 speed bicycle hub transmission.

The Rohloff SPEEDHUB 500/14 can be optimized through the use of differetn peripheral components for mounting into almost every type of bicycle frame available. One must simply selecting and combine the correct transmission components mentioned below.

Axle types

The Rohloff SPEEDHUB 500/14 is available with two types of axle. The CC model denotes an axle that is secured in the frame with a quick release skewer.

The TS model denotes an axle with threaded ends on both sides. The axle ends are secured in the frame with standard M10x1 nuts. The 14 speed bicycle hub transmission is identical regardless of axle type.

The A12 model is constructed for frames fitted with dropouts which accept 12 thru-axle systems (DT/Maxle, Sysntace, Shimano E-Thru). A12 SPEEDHUB models can only be supplied upon receipt of 3 documents completed during a special dropout measurement procedure. Our distributors or service partners will be able to supply the special A12 measurement kit for this purpose upon request.

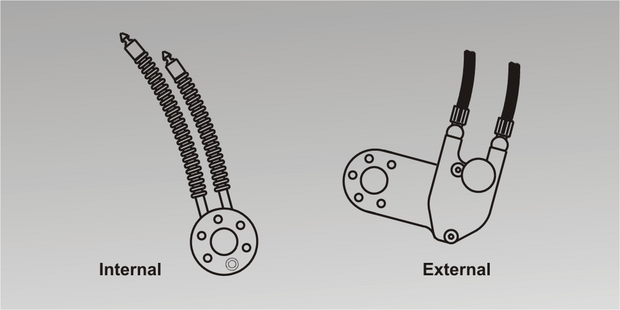

Gear mech

Internal gear mech

When using an Internal Gear Mech, the shifter cables run from the twist shifter to a cable guide mounted to the frame. It can be mounted directly either on the brake boss or attached to the frame by means of either a clamp or threaded insert respectively. Gear selection in the hub is controlled by an internal hub cable. This is in turn is connected to the shifter cables by means of two bayonet connectors thus enabling swift and simple detachment for wheel removal. The internal gear mech can not be combined with rear disc brake assemblies as the bayonet connectors would clash with the disc rotor. The pitch circle diameter of the axle plate allows the Internal Gear Mech to be adjusted in 30° steps, ensuring optimum cable routing on almost all types of frame.

External gear mech

When using an external gear mech, the shifter cables runcontinuously from the twist shifter to the cable box. A separate cable guide is unnecessary. For quick and easy removal of the rear wheel, the cable box can be removed from the external transfer box. All disc brake versions (DB) of the Rohloff SPEEDHUB 500/14 are equipped with this type of External Gear Mech. The pitch circle diameter of the axle plate allows the Gear Mech to be adjusted in 30° steps, ensuring optimum cable routing on almost all types of frame.

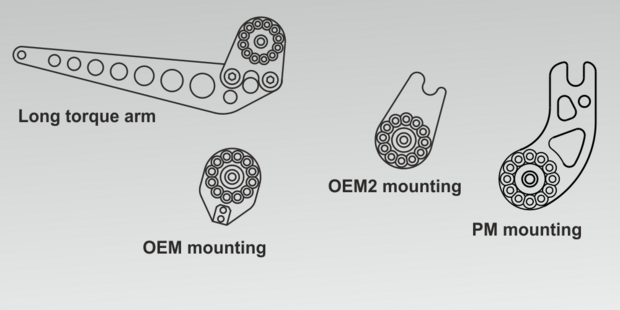

Torque support

With all gear hubs the axle attempts to rotate whilst under load (riding). When a gear below #11 is engaged on the SPEEDHUB, the axle attempts to rotate backwards. When a gear greater than #11 is engaged, the axle attempts to rotate forwards.

The force with which the axle attempts to rotate is referred to as support torque. The magnitude of torque generated is dependent on the applied pedal force and current gear selection. This must be absorbed by an anti-rotational device on the frame. On simple three-speed IGHs, a flat sided axle is sufficient to secure the torque within the dropout. A high performance IGH like the Rohloff SPEEDHUB 500/14 requires a much greater level of stability to absorb torque given the large range of gear ratios.

Depending on the frame type, one of the options can be selected to anchor this support torque to the frame.

- Standard: axleplate with long torque arm

- OEM: axleplate (for 37mm vertical OEM dropouts)

- OEM2: axleplate (in combination with SPEEDBONE, Monkey Bone an OEM2 M5 Adapter)

- CC PM: axleplate (in combination with PM Bone)

- A12 PM: axleplate (in combination with A12 axle and PM Bone)