Riding

Shifting

All 14 gears of the Rohloff SPEEDHUB 500/14 can be selected via one twist shifter, making it possible to change up or down by one or more gears, in one turn.

The mark on the twist shifter casing next to the gear numbers informs the user of which gear has been selected. The assembly instructions show the twist shifter being fitted to the right hand side of the handlebars, however, in special circumstances it is possible to fit the twist shifter to the left hand side. When rotating the twist shifter in the direction of #14, a harder, faster gear is selected. When rotating the twist shifter in the direction of #1, an easier, slower gear is selected.

In contrast to other gear systems on the market, with the Rohloff SPEEDHUB 500/14 there is no delay between gear selection on the twist shifter and gear change in the hub. The moment the notch can be felt in the twist shifter, the gear has been changed. Therefore a quick and failure free gear change is possible whilst riding and also when stationary.

When changing, gear coupling elements inside the hub must move and when there is more pressure on the pedals it is obvious there is more pressure on these coupling elements resulting in a harder gear change. Whilst stationary or when there is less pressure on the pedals, the twist shifter has less resistance and therefore a lighter gear change is possible. In a situation whereby it is not possible to reduce the pressure on the pedals (e.g. hill climbing), it is still possible to change gear quickly and smoothly. Simply change gear when the cranks are in a straight up-down position where hardly any pressure is being applied upon the pedals.

Operational Noise

One of two different riding noises could be heard depending upon which gear is selected.

A construction characteristic produces a freewheeling noise which is can be heard in most gears - particularly noticeable in gears #5, #6 & #7. A higher frequency is produced when riding with a higher force upon the pedals. This causes the volume of the lower gears to increase towards gear #7 - a typical characteristic of straight-toothed precision gears.

Different frame designs can amplify or deaden these audible noises because the tubes of the frames react as a resonator for the sound waves. Larger diameter tubes offer more room for sound waves thus the noise is amplified.

Different noises are noticeable whilst freewheeling depending on which gear is currently selected. This is due to different elements of the gear mechanism rotating within the hub. The construction of some frames can also reveal a slight vibration in the gears where this noise is loudest.

Break-in Period

All the gears and coupling elements of the Rohloff SPEEDHUB 500/14 are built from specially hardened steel and are precision finished.

In the first 1000km use, the Rohloff SPEEDHUB 500/14 loses microscopic particles from all functioning components as part of the hubs last fine filing.

After this process is completed the riding noises quieten, the vibrations (if present) will decrease and the changing of gears becomes easier. During this process it is not necessary to take extra special care.

Pushing the Bike

Should the bike be pushed, it is possible that the cranks could also start to turn. This occurs due to the hub seal automatically activating the sprocket.

Bad seals and/or a very light running bottom bracket make it easier for the cranks to turn. A drop of Rohloff cleaning oil (Art. #8402) through the holes in the sprocket onto the hub seal will reduce this activation.

Wheel Removal and Installation

Tips for Cycle Tours

The Rohloff SPEEDHUB 500/14 immediately proved itself the altimate gear system, especially for tours and long journeys due to its durability, long life and the strength of the final wheel itself. Of course, one should remember that even good quality components can all be hindered from performing correctly due to accident damage, excessive dirt, over lubrication or wear, and as such, should be correctly maintained and checked regularly.

We therefore suggest that you should always carry a few important spares and tools with you, in regards to these other components.

We have compiled a list of tools and other small parts to take with you.

Transportation

If transporting a bike fitted with a Rohloff SPEEDHUB 500/14, care should be taken that the rear wheel is transported in an upright position.

Great changes in the air temperature/pressure can be experienced in a car or airplane. When the wheel lies on its side, oil could seep out of the seals because the oil is sitting directly over these seals on either the left or the right side. Transportation in the upright position will prevent the air temperature/pressure in having an effect over the Rohloff SPEEDHUB 500/14.

If it is not possible to transport the wheel in the upright position due to according packaging requirements, don't worry. The leakage of oil will not cause any damage.

Serial Number / Warranty

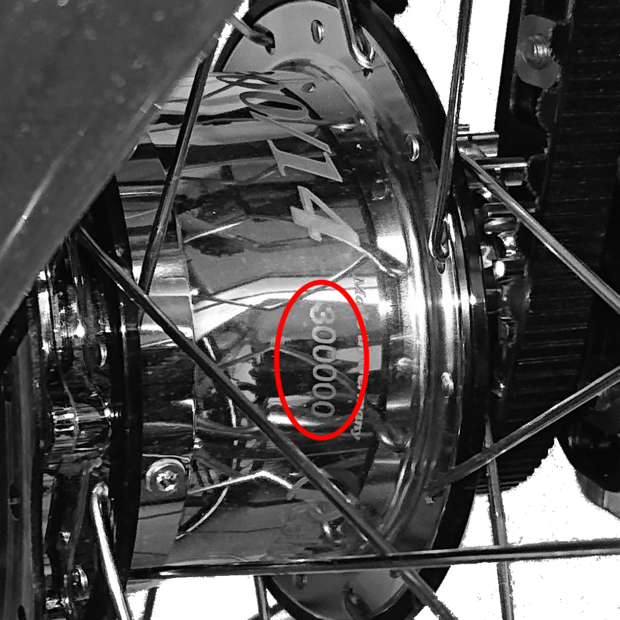

Each Rohloff SPEEDHUB 500/14 has an individual Serial Number. This can be found printed either on the hub shell sticker or engraved into the hub shell. This Serial Number informs us about the production year and is important for guarantee or warranty claims, as well as a acting as proof of ownership.

Safety Information

Bike riding is fun but it is also tied up with dangers. When your bike is not regularly maintained and kept in good condition, these dangers increase.

These dangers, however, can be prevented when you read this handbook and the following safety information carefully. A incorrect fitment of the vital components could result in a crash, with possible life threatening injuries.

Mounting

- We recommend all fitting and assembly of our products should be carried out by a professionally qualified workshop.

- Improper work and customizing may result in malfunction and this in turn could lead to accidents occuring.

- Please make sure that you have the correct Rohloff SPEEDHUB 500/14 model for your type of bike frame.

- All the bolts must be secured to the given tightening torques.

- The smallest permitted sprocket ratio must not be undercut.

- If a chain tensioner is in use at the rear, a chain guide must be used in conjunction up front to prevent the chain from springing off the chainring.

- On rear suspension frames the chain must be kept at a suitable length that allows the rear triangle to move the full amount of shock travel.

- When filling the Rohloff SPEEDHUB 500/14 with oil for the first time as well as when changing the oil, make sure you use only Rohloff SPEEDHUB oils as recommended for the Rohloff SPEEDHUB 500/14.

Usage

Before riding with your Rohloff SPEEDHUB 500/14 please follow the next few steps in order to truly trust the products service.

- Let your bike be regularly checked by a specialist workshop to make sure that it functions safely.

- When starting off, especially after a gear change, you must check the gear has engaged properly.

- Make sure you carry out the safety checks on all the other mounted components of your bike.

- Before a long journey or tour, a test ride must be taken. Through this process any mounting mistakes or loss of functions can be noticed and corrected. Also see ‘Transport/Info for the tour’.

- When utilizing a bicycle equipped with a ‘Gates Carbon Drive’ belt transmission, it is important to adhere to the manufacturers instructions printed within their Owners Manual which you can find here.

- Cycling through deep water with a SPEEDHUB is not permitted. Do not submerge the SPEEDHUB as water will penetrate the gear-unit.

- Unprotected transportation on a motor vehicle through heavy rain can also lead to water penetration and should be avoided.

- An oil change should be completed immediately if you believe water may have penetrated the gear-unit. This will ensure any potentially penetrated moisture is rinsed back out.

Check regularly ...

- That the Rohloff SPEEDHUB 500/14 is correctly secured to the frame (quick-release axle max. 7Nm/62in.lbs. / threaded axle max. 35Nm/310in.lbs. / A12 securing bolts max. 20Nm/177in.lbs.)

- That all hub cap screws are tightened to the correct torque (4Nm), especially on DB versions of the Rohloff SPEEDHUB 500/14

- That all 4 brake rotor securing bolts are tightened to the correct torque (10Nm)

- That the hubs torque securing system is correctly fastened to the frame

- That all axleplate screws are secured to the correct torque value (ATTENTION: - ensure torque wrench is correctly calibrated due to low torque value (3Nm))

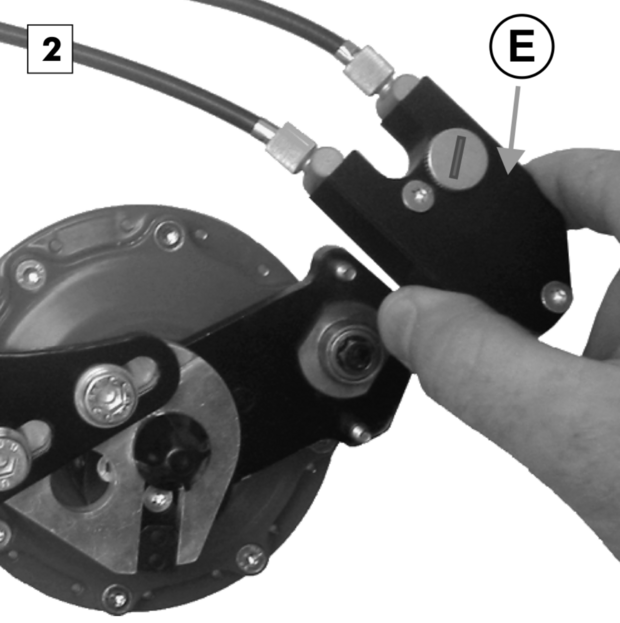

- That the shifter cables and connectors are correctly and securely joined (bayonet connectors, external gear mech cable box, E-14 cable connectors)

- That all spokes of a wheel with mounted and inflated tire, are tensioned to a min. 1000N

- That the brake surfaces are free from oil and grease

- That the parts on your bike are not damaged or failing to function properly as the result of accident damage. The use of damaged parts can easily lead to further accidents and injuries