Tools

Professional tools for your bicycle transmission. Measure correctly and fasten safely.

The Revolver 3 chain riveting tool is capable of safely joining and securing all bicycle chains from singlespeed to 11-speed and riveting those chains with re-useable pins to the highest workshop quality. Check the wear level of your chain and HG sprockets using the Caliber 2 and HG-Check tools respectively. Replace damaged or worn SPEEDHUB sprockets and carriers with the use of our SPEEDHUB Sprocket Remover Tool and you’re your SPEEDHUB shifter cables correctly with the help of our Cable Hook and Measurement tube tools.

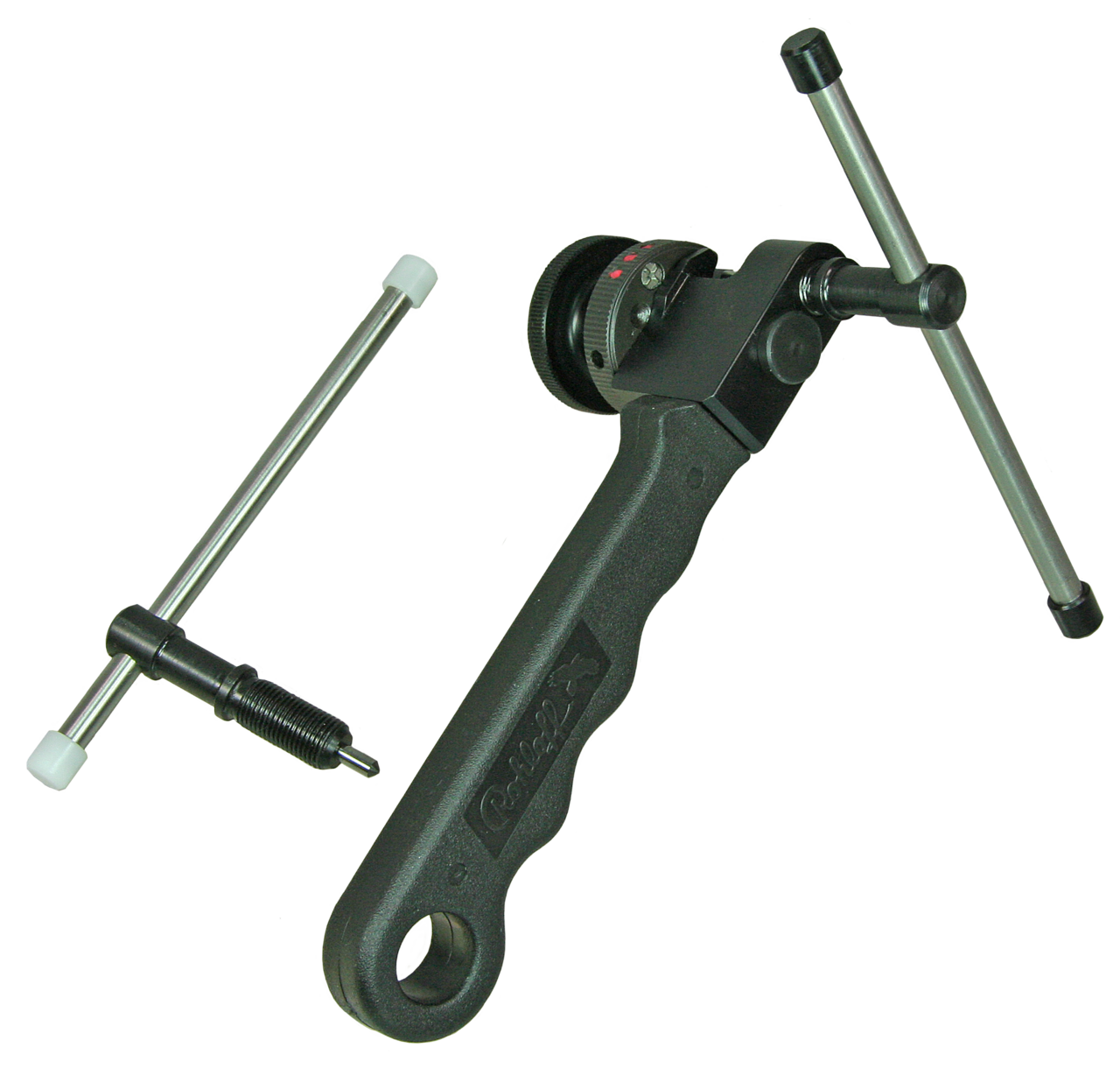

Revolver 3

Universal Security Riveting Tool (…and one for all!)

Regardless as to which attachment method your bicycle chain uses, the Revolver 3 is capable of fastening them all. Bicycle chains are subjected to enormous forces and in a world where ever thinner, lighter materials are implemented, the demands we place upon the material become less and less rational. It is therefore all the more necessary that the components we use are correctly mounted. The Revolver 3 is the professional chain tool, trusted by countless high-class workshops worldwide. Able to open and safely close all derailleur chains as well as singlespeed chains in 1/2” x 3/32” and 1/2” x 1/8”. The current generation of 12-speed chains can be equally opened and closed with the Revolver 3 tool as can all 10, 11 and 12 speed Campagnolo chains thanks to the second spindle included with the Revolver.

Our Revolver 3 is constructed from high quality nylon and hardened steel, making use of incredibly hard Carbide where necessary. This tool is in constant use in bicycle workshops worldwide and can be found in the toolbox of many a hobby mechanic, ensuring a perfectly joined chain is fitted to both race and everyday bikes.

Caliber 2

Keep an eye on your chain wear.

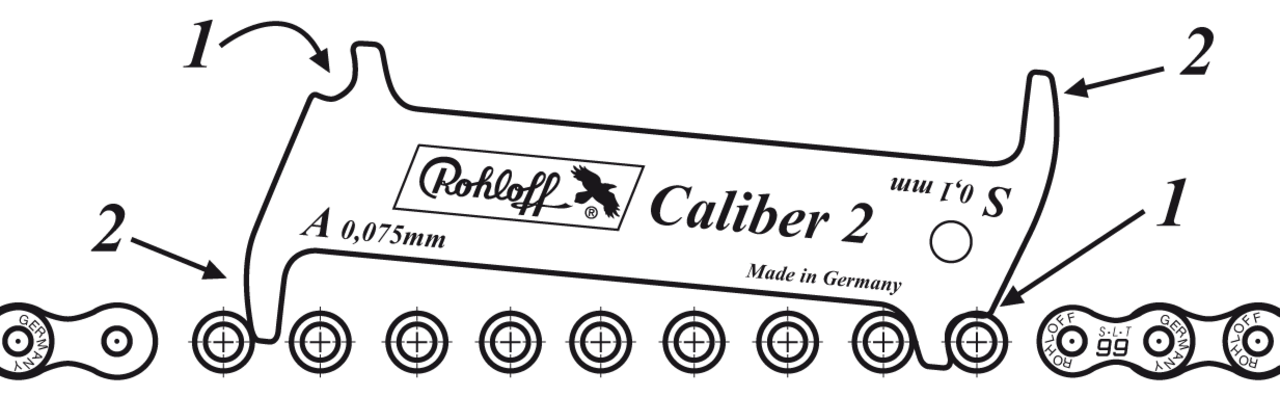

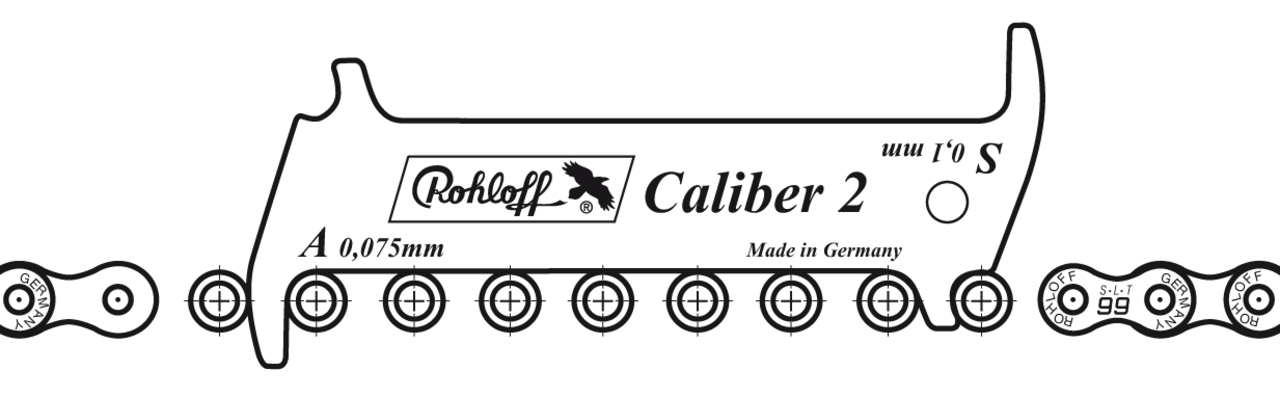

Only a fully functioning chain is able to perform smoothly – and only then, are sprockets and chainrings protected from excessive wear. The Rohloff Caliber 2 tool shows at a glance if its time to replace those sprockets. Replace your sprockets and chainrings at the exact point where they reach their limits and in doing so, protect your sprockets from excessive wear.

The Caliber 2 allows you to quickly determine chain wear before your chain gets to this condition.

If side A of the Rohloff Caliber 2 tool sinks in fully, allowing the Rohloff Caliber 2 to lie flat on the chain rollers (Figure II), the chain wear factor has reached 0.075mm per link. To protect ALUMINUM sprockets from premature wear, chain replacement is recommended at this time. If side S of the Caliber 2 tool sinks in fully, the chain wear factor is 0.1mm per link. The chain should now be replaced to avoid skipping and to prevent wear on STEEL sprockets.

HG-Check

Perfect transmission thanks to fresh sprockets

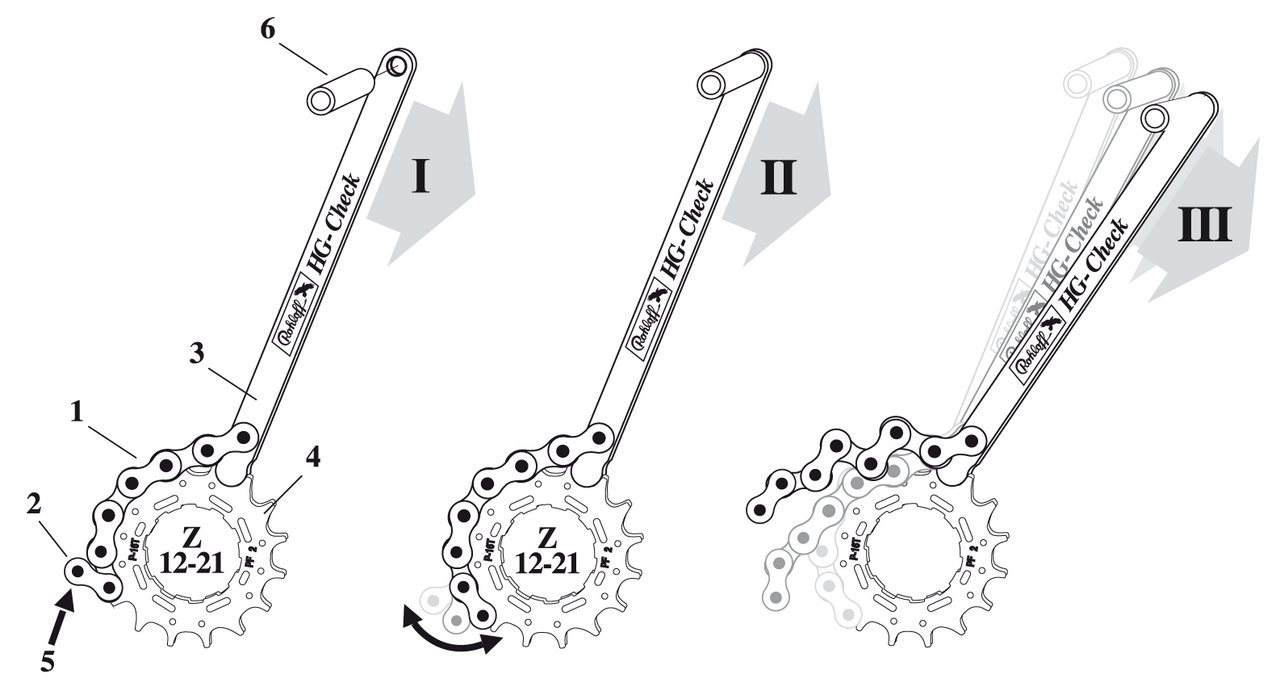

Ride with the highest transmission efficiency. Place your trust in a reliable transmission. The Rohloff HG-CHECK enables you to concentrate on your tour or race without worrying about your transmission letting you down. The HG-CHECK tool allows you to check the condition of your Shimano sprockets easily.

Place the Rohloff HG-Check on each sprocket of the HG-IG cassette block that you wish to check.

Sprockets with a tooth count between 12 and 21 should be measured as follows: place the last link of the measurement chain (2) on the sprocket with the test roller (5) inclining slightly outwards and press it against the measurement chain (Figure I). With the other hand forcefully press the handle (approx. 10 kg/22 lb) in the drive direction and swing the test roller (5) into the tooth pocket while the measurement chain (1) is under load.

If the test roller (5) moves freely in the tooth pocket (Figure II), your HG-IG sprocket is still working well. This indicates that even a new chain will run well on this used sprocket.

If the test roller (5) hooks on the tip of the tooth or if you need to use some force to move it into the tooth pocket, the sprocket should be replaced.

If the measurement chain (1) slides from the sprocket profile while the handle (6) is under pressure (Fig. III), the amount of wear is excessive. Sprockets with more than 21 teeth are rarely worn out, so they should not cause any problems while in use. Therefore, a check up is normally not necessary. Nevertheless, you can check whether the measurement chain (1) slips off the tooth profile while putting pressure on the grip (6) (Figure III)

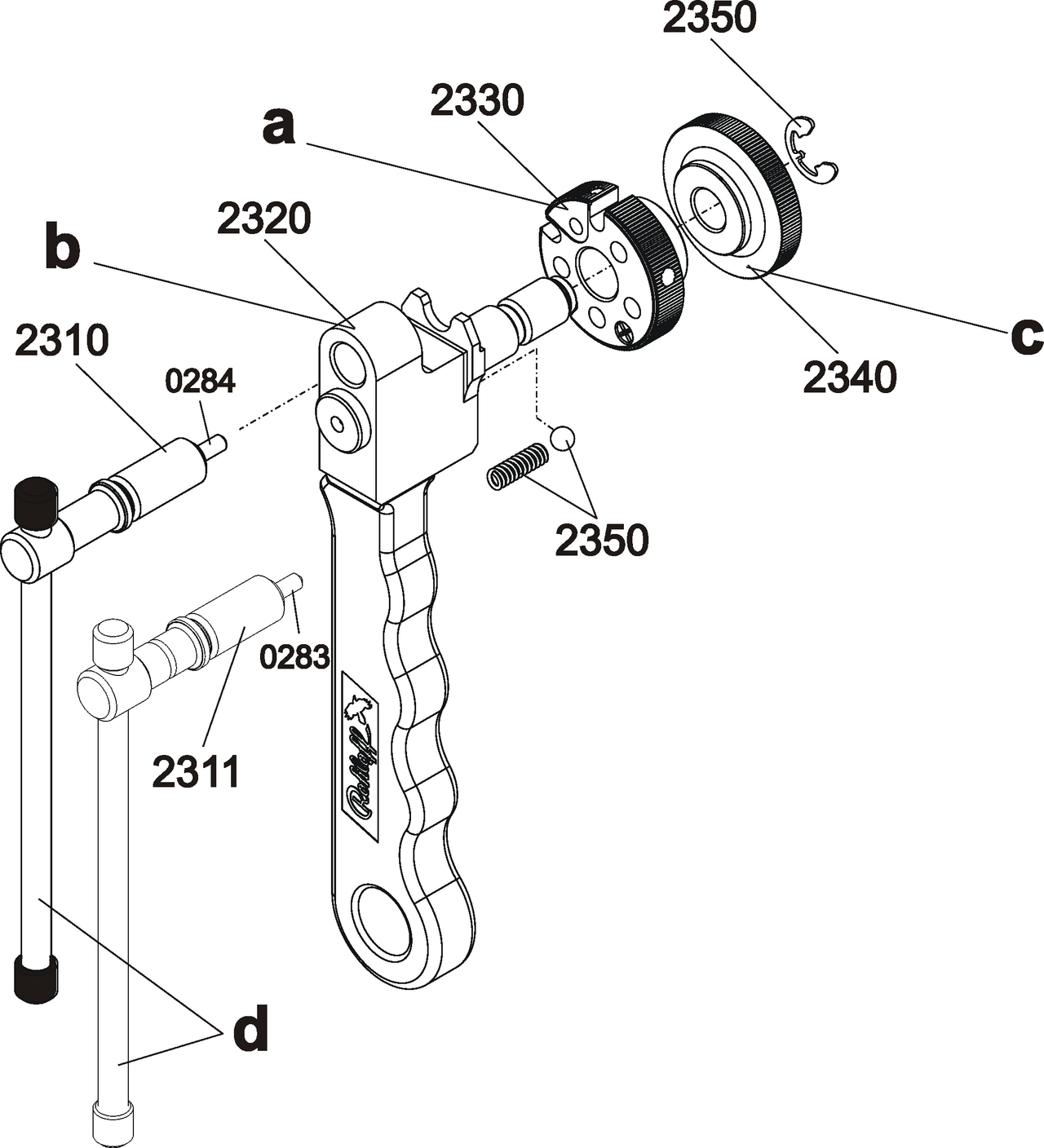

Sprocket tool

Threaded sprocket and sprocket Carrier remover tool

The Rohloff Sprocket Remover Tool should be used together with a chain-whip and 24mm wrench, to remove original threaded sprockets from a SPEEDHUB 500/14 unit. Removal of our new splined sprocket Carrier and original Carbon Drive Carrier can also be accomplished with the use of this tool.

The lock-ring which secures Carbon Drive sprockets to the Lock-ring Carrier, can be loosened and secured to the correct torque, using the special lock-ring tool (Art.#8518)

Set of cutting aids

Easily trim shifter cables to the correct length

It is near impossible to cut SPEEDHUB shifter cables more precisely. The brass measurement tubes are simply slipped over the shifter cables, pushed up to the housing and the protruding inner cable then trimmed at the end. Set consists of 2 tubes; one at 165mm for the internal hub cable, and one at 200mm for the external shifter cable.

Cable hook

Shifter cable trimming tool for the Internal Gear Mech.

The length of the shifter cables protruding after the cable adjusters of an Internal Gear Mech, can vary wildly depending upon the frames rear triangle length. The Cable Hook tool enables shifter cables for Internal Gear Mechs to be trimmed precisely, regardless of frame design.

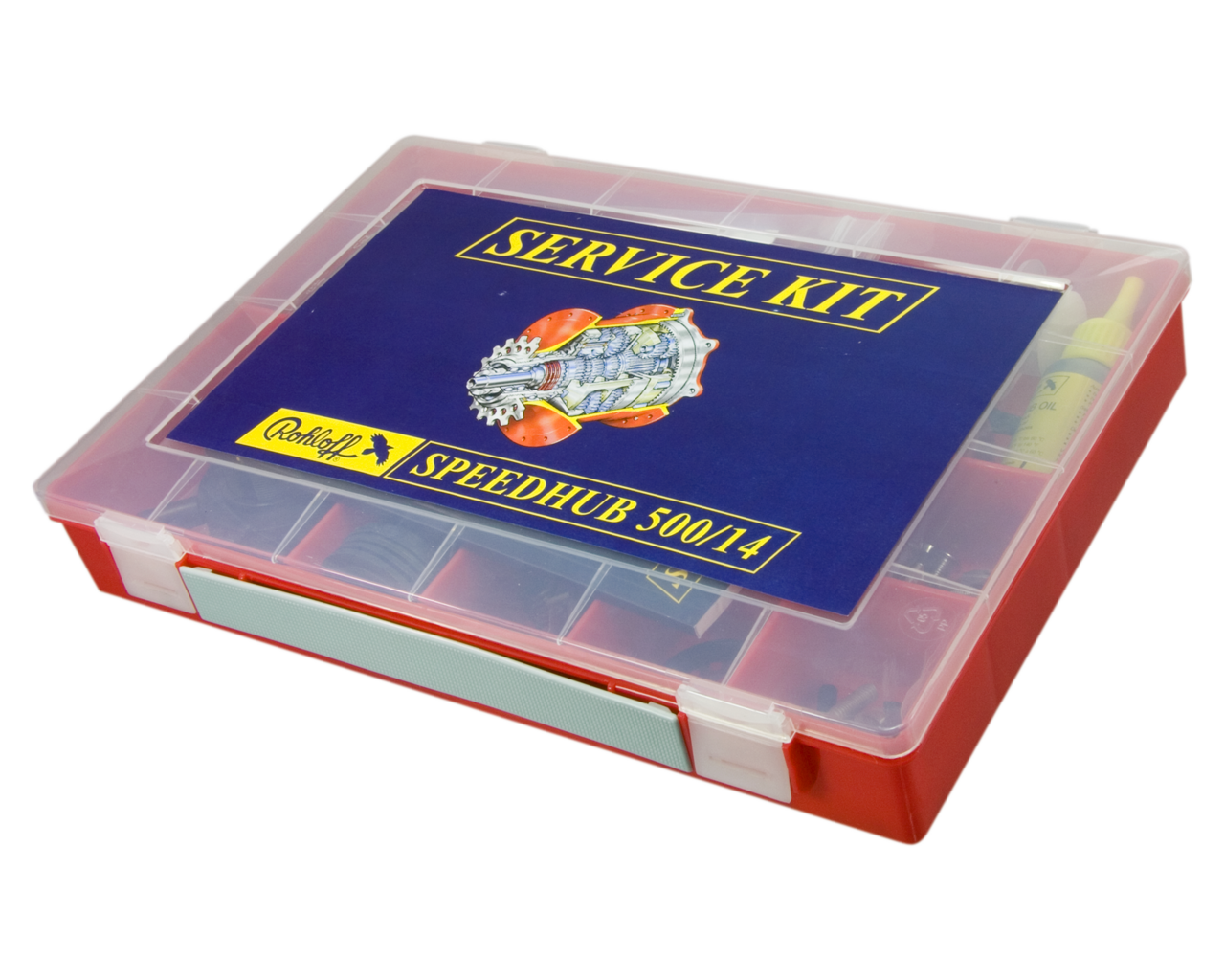

Service Box Content

| Description: | Article. No.: | |

| 8190 | Rubber grip for twist shifter "light" | 1 |

| 8191 | Twist shifter cable stoppers 1+14 for twist shifter "light" | 2 |

| 8193 | TX20 screws and clamp for twist shifter "light" | 1 |

| 8194 | Cable pulley for twist shifter "light" | 1 |

| 8205 | Drain screw | 1 |

| 8231 | Torque Arm screws with washers | 1 |

| 8236 | Axle-plate Torx screws (6 pcs.) | 2 |

| 8243 | Chainring spacers (5 units) | 1 |

| 8248 | Conversion kit Chain Tensioner | 1 |

| 8251 | Chain Tensioner jockey wheels | 1 |

| 8257 | Long mounting bolt + Distancing washers for chain tensioner | 1 |

| 8260 | Cable Guide 0° (straight type) with frame clamp | 1 |

| 8262 | Pipe Clamps for Art.No. 8240 | 1 |

| 8263 | TS Axle nuts (M10 x 1) including washers | 1 |

| 8268 | Shifter cable set: 2x inner (1.1mm) + housing 1.8m | 1 |

| 8271 | Hub cables for Internal incl. tubes and ties | 1 |

| 8274 | Bayonet connectors, 1x male type, 1x female type | 1 |

| 8275 | Freewheel springs (2 units) | 1 |

| 8295 | Owners Manual Rohloff SPEEDHUB 500/14 | 1 |

| 8410 | Oil change kit (with syringe, drain screw and filler hose) | 1 |

| 8504 | TX20 Torx T-Grip key | 1 |

| 8506 | Cable hook for shifter cables (internal gear mech) | 1 |

| 8508 | Sprocket tool 135/142/170/177 | 1 |

| 8517 | Silencing Grease | 2 |

| 8540 | Splined Carrier | 1 |

| 8540 | Splined Carrier with snap ring | 1 |

| 8540s | Splined Carrier "slim" with snap ring | 1 |

| 8544 | Splined Sprocket 16T | 1 |

| 8570 | Grub screw bayonet connectors | 1 |

| 8573 | Hub cable Easy Set (from Serial no. 25300) | 1 |

| 8701 | Empty Box | 1 |

| 8704 | Cable adjusters for cable box | 1 |

| 8706 | Washer and circlip for Chain Tensioner | 1 |

| 8707 | Bolt and circlip for locating fork (long torque arm) | 1 |

| 8709 | Bayonet springs | 1 |

| 8710 | Paper gasket kit for axle-ring | 1 |

| 8713 | Set of hub/shifter cable measuring aids 165 + 200mm | 1 |

E-14 Diagnosic Kit Content

| Description: | Article. No.: | Amount: |

| 8801 | Rohloff E-14 Switch Unit | 1 |

| 8802 | Rohloff E-14 DC/DC CAN Converter | 1 |

| 8803 | Rohloff E-14 Shifter Unit (for diagnostic and cross exchange only, not for re-sale) | 1 |

| 8810 | 1000mm Extension Cable (lilac, 6-pole, Rohloff E-14 Shifter Unit ⟷ Rohloff E-14 DC/DC CAN Converter) | 1 |

| 8811 | 1000mm Extension Cable (blue, 4-pole, Rohloff E-14 DC/DC CAN Converter ⟷ Rohloff E-14 Switch Unit) | 1 |

| 8714 | Axleplate Screws and Paper Gasket Set | 1 |

| Original Rohloff E-14 Owners Manual | 1 |

![[Translate to en:] 8508 Ritzelabzieher](/fileadmin/_processed_/4/7/csm_8508_0eda168a4d.png)

![[Translate to en:] 8509 XXL FAT Bikes](/fileadmin/_processed_/6/e/csm_8509_08c009d4b2.png)

![[Translate to en:] 8509 Lock-Ring Tool](/fileadmin/_processed_/5/a/csm_8518_01_c6300179b5.png)