Planetary Gear System

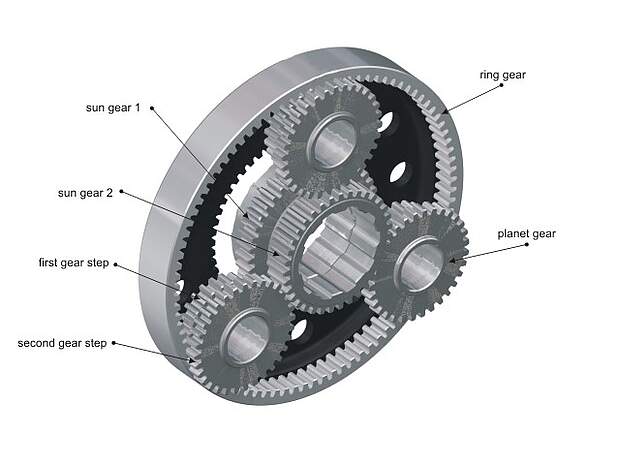

A planetary transmission system (or Epicyclic system as it is also known), consists normally of a centrally pivoted sun gear, a ring gear and several planet gears which rotate between these.

This assembly concept explains the term planetary transmission, as the planet gears rotate around the sun gear as in the astronomical sense the planets rotate around our sun.

The advantage of a planetary transmission is determined by load distribution over multiple planet gears. It is thereby possible to transfer high torques utilizing a compact design.

Gear assembly 1 and gear assembly 2 of the Rohloff SPEEDHUB 500/14 have two selectable sun gears. The first gear step of the stepped planet gears engages with sun gear #1. The second gear step engages with sun gear #2. With sun gear 1 or 2 coupled to the axle,or the coupling of sun gear 1 with the ring gear, three ratio variations are achievable with each gear assembly.

Direct Gear 1:1

Example Gear Assy (1) and (2)

With direct gear selected in gear assy (1) or (2), the sun gear 1 is coupled with the ring gear in gear assy (1) or gear assy (2) respectively. The sun gear 1 and ring gear then rotate together at the same speed. The stepped planet gears do not unroll. Thus the gear ratio is 1:1.

Gear assy (3) aquires direct gear based on the same principle. Sun gear 3 and ring gear 3 are directly coupled.

Sun gear #1 fixed

Example Gear Assembly #1

The input from gear assy (1) is transferred via the ring gear. When the sun gear 1 is coupled to the axle, the first gear step of the stepped planet gears rolls off between the fixed sun gear 1, and the rotating ring gear. One rotation of the ring gear (green arrow) results in 0.682 rotations of the planet carrier (red arrow).

Example Gear Assembly #2

In this case of gear assy #2 the input is transferred via the planet carrier and the output is transferred via the ring gear. The rotational relationship is hereby reversed from gear assy #1. The planet carrier (red arrow) rotates 0.682 of a complete rotation resulting in one full rotation of the ring gear (green arrow) when sun gear #1 is coupled to the axle.

Sun gear #2 fixed

Example Gear Assembly #1

The input from gear assy #1 is transferred via the ring gear. When the sun gear #2 is coupled to the axle, the stepped planetary gears are forced to rotate around the fixed sun gear on their second gear step. The first gear step rolls into the ring gear. One full rotation of the ring gear (green arrow) results in 0.774 rotations of the planet carrier (red arrow). Sun gear #1 is carried forward without function, as it is driven on by the first gear step of the rotating planetary gears.

Example Gear Assembly #2

With gear assy #2 the input drive is transferred via the planet carrier. The output is transferred via the ring gear. The rotational relationship is hereby reversed, as opposed to gear assy #1. The planet carrier (green arrow) rotates 0.774 of a complete rotation, resulting in one full rotation of the ring gear (red arrow), when sun gear #2 is coupled to the axle.