Questions about your SPEEDHUB 500/14

- Mounting Components

- Tuning Parts

- Axle Plates and Dropouts

- Primary Transmission, Chain, Beltdrivesystem

- E-14

- Wheel/Spokes/Nipples

- Oil and Lubrication

- Trouble Shooting

- Gear Mech

- Disk Brakes

- Maintenance and Service

- Speedhub Miscellaneous

Traveling with Your SPEEDHUB

Rohloff Specialist Tools

Miscellaneous

Mounting Components

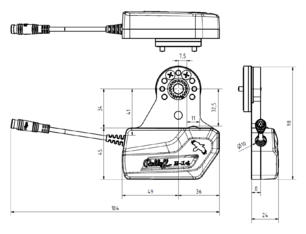

Trailer Hitch with E-14 (Electronic Gear Mech) or EX (External Gear Mech)

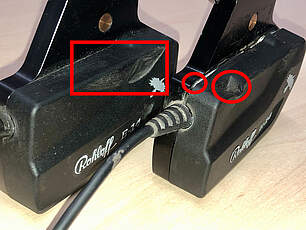

Use of a trailer hitch in conjunction with a Rohloff SPEEDHUB 500/14 is generally not a problem as long as one ensures that neither trailer nor hitch collide with any Rohloff component during a ride. This is especially important when used with an E-14 equipped SPEEDHUB unit. The E-14 shifter unit has a plastic cap which can easily be deformed when pressure is applied from collision with trailer hitches. The cap deformation can compromise the seal quality of this component and lead to further issues so must be avoided!

Use of washers/spacers or special adapters offered by the trailer hitch manufacturer should be used if necessary, to ensure enough clearance between the two components and thus avoid the sort of damage outlined above.

ATTENTION:

Bicycle trailer hitches which mount directly to the 12mm thru-axle, must not be used in conjunction with an A12 SPEEDHUB 500/14 unit. The additional thickness of the trailer hitch will hinder the specially produced M7 mounting bolt (increased stiffness) from penetrating the SPEEDHUB axle or axleplate deep enough. Threads will be stripped as there are not enough to adequately ensure the SPEEDHUB is mounted safely into the frame. A loose, insufficiently secured SPEEDHUB could lead to accidents and injuries so must be avoided.

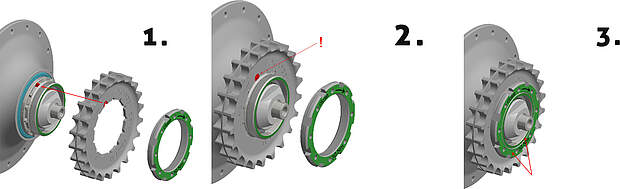

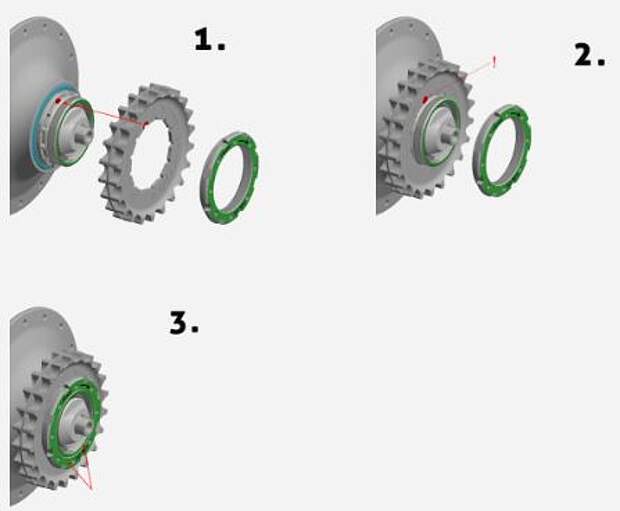

Mounting Instructions - Splined Carrier with Lock-Ring (Art.#8540L / Art.#8540SL)

- The Gates Carbon Drive splined sprocket must be placed over the Rohloff Carrier L/SL, as illustrated.

- Ensure the sprocket remains correctly positioned on the carrier, while threading the lock-ring onto the driver!

- The Lock-Ring must rest flush against the sprocket after threading onto the Rohloff Carrier L/SL! Finally, secure lock-ring to 30Nm (do not use screw locking agents) using a calibrated torque wrench.

Should operational noises appear when using either Gates Carbon Drive or Rohloff chain sprockets with this carrier, then re-check the components are mounted correctly, and reference the following FAQ.

FR: Instructions de montage du support cannelé (art. 8540L / 8540SL) avec Lockring (bague filetée 8538)

- La poulie Gates doit être insérée sur le support cannelé Rohloff L/SL comme illustré.

- Assurez-vous que la poulie est bien en butée sur ses cannelures avant de visser le Lockring.

- Nach korrekter Montage muss der Lock-Ring bündig mit dem Rohloff Carrier L abschließen! Danach mit 30Nm Anzugsmoment anziehen (kein Schraubensicherungsmittel verwenden).

Sollten Geräusche mit Riemenscheibe oder Rohloff Ritzel auftreten, kontrollieren Sie bitte die korrekte Montage und beachten folgenden FAQ Beitrag.

NL: Montage van de Splined Carrier L met Lock-ring voor Gates / rondsels (art.nr. 8540L)

- De Gates-poelie moet op de Rohloff Carrier L worden geplaatst zoals op de afbeelding.

- Zorg ervoor dat de Gates-riemschijf / rondsel in de juiste positie blijft wanneer u de Lock-ring vastschroeft!

- Na correcte montage moet de Lock-ring naadloos gelijk liggen met de Rohloff Carrier L! Draai vervolgens vast met een aandraaimoment van 30 Nm (gebruik geen schroefborgmiddel!).

Als er abnormale geluiden te horen zijn bij de riemschijf of het Rohloff-rondsel, controleer dan de juiste montage en let op het volgende FAQ-artikel.

Gates Carbon Drive - Operational Noises

It is possible that the belt will produce operational noises, when rubbing against the center-track. This can occur due to incorrect belt-line, incorrect wheel alignment or component wear level. Spraying water onto the belt may eliminate the noise temporarily however a permanent solution will only be attained via correction of the belt line and/or wheel alignment, or the replacement of worn components.

A further cause of operational noise is a loose carrier lock-nut. Should your lock-nut come loose, then apply a small drop of thread sealant to the carrier thread before tightening the lock-nut to the correct torque.

Occasionally, noises are heard after riding in dirty conditions - especially when mountain biking through wet, sandy conditions whereby the sand then adheres to the belt teeth. In such a case, a quick rinse down with a garden hose will usually clear the belt of this sand and eliminate the noises. In select cases however, the sand particles will be embedded into the belt and cause the system to squeak as the belt with hard sand particles, rubs over the metal sprockets. If the noise persists after rinsing with water, then the remedy is as follows: spray the belt again with water and wait for this to dry off. Now apply a thin coating of silicone spray to the belt teeth. This dries immediately and accelerates the speed at which sand particles are then shed from the belt. This has no negative effect upon the life-expectancy of the Gates Carbon Drive components. Gates recommend the use of this product.

Ensure the Splined Carrier L (with Lock-Ring) Art. 8540L is always used in conjunction with Gates Carbon Drive splined Rohloff sprockets. Pay close attention to the mounting instructions (30Nm do not use screw locking agents), to avoid additional operational noises!

Weberkupplung – In Combination With Rohloff SPEEDHUB 500/14?

Bicycle trailer hitches which mount directly to the 12mm thru-axle, must not be used in conjunction with an A12 SPEEDHUB 500/14 unit. The additional thickness of the trailer hitch will hinder the specially produced M7 mounting bolt (increased stiffness) from penetrating the SPEEDHUB axle or axleplate deep enough. Threads will be stripped as there are not enough to adequately ensure the SPEEDHUB is mounted safely into the frame. A loose, insufficiently secured SPEEDHUB could lead to accidents and injuries so must be avoided.

Weber Kupplung type B:

With this model, a small section of the stand must be filed back in order to allow the long torque arm to pass by (not necessary with OEM and OEM2 versions).

The safety and stability of the stand will not be affected through this procedure.

Weber Kupplung type E:

This model includes a safety cable. This will need to be a little longer than normal when in use with the Rohloff SPEEDHUB 500/14 due to the size of the hubs diameter.

Make sure to inform the retailer at the time of purchase that the trailer is to be used in combination with a Rohloff SPEEDHUB 500/14.

Weber Kupplung Typ ER:

Newest version of the successful E-Kupplung:

The ER-Kupplung has to be screwed directly on the adjustable Rohloff dropout.

Weber CR-Kupplung:

This special version can be mounted onto the adjustable Rohloff dropout with both screws.

Version C+, for bikes with Rohloff dropouts:

It's the solution for adjustable Rohloff dropouts with integrated Lösung Monoport Kupplung! The C+ drpopout will be mounted to the bike instead of the original Rohloff dropout. The result: A perfekt joining just a little bit better and easier to achieve.

Pictures and more detailed information under:

http://www.weber-products.de/kupplungen/index.html

Bike Components - which are recommended? (Chains, Chain Rings, Cranks, Sprockets, Chain Tensioner, Chain Guide)

Chains:

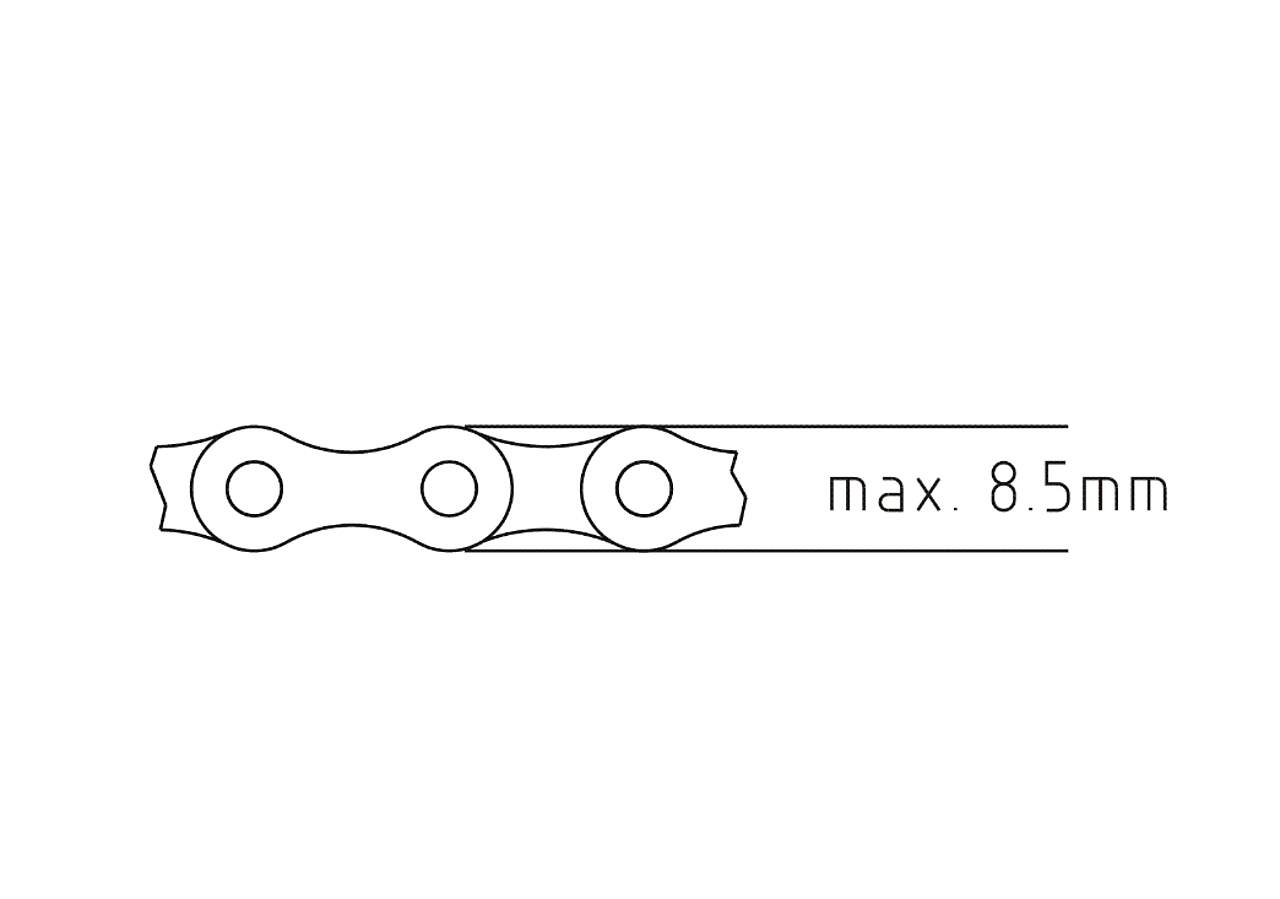

All 1/2" x 3/32" eight and nine speed chains are suitable for use with the Rohloff SPEEDHUB 500/14 although we recommend the eight speed version due to its slightly thicker link plates. All 1/2" x 1/8" bicycle chains (max. 8,5mm height) are also compatible with the Rohloff SPEEDHUB 500/14 sprockets. These thicker chains however are by no means stronger and not recommended for use with the Rohloff SPEEDHUB 500/14. In addition to this, they are not designed for the high mileages achieved with a SPEEDHUB and thus are subject to faster wear. These 1/2" x 1/8" chains are also unfortunately too wide to pass through the Rohloff chain tensioner.

Chain Rings:

All chain rings for a 1/2"x 3/32" chains can be used together with the Rohloff SPEEDHUB 500/14.

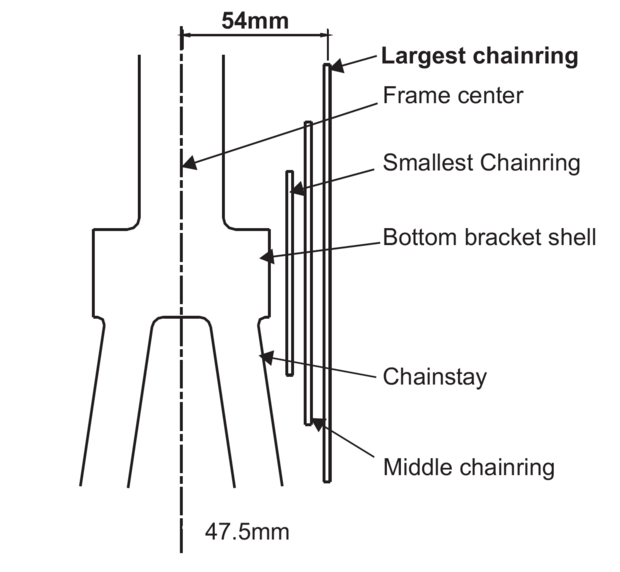

Cranks (chainstay):

The use of threaded sprockets in the sizes 15, 16 and 17 tooth, will produce a chain line of approximately 54mm from the frame center. This requires the use of the outer chainring from triple crank sets such as Shimano (Largest chainring: 54mm, middle chain ring 47.5mm). The middle and smallest chainrings are not required and can be disposed of. After the disassembly of the middle and smallest chainrings, the bolts for securing the largest chain ring will now be too long. For this reason the Rohloff SPEEDHUB 500/14 small parts bag includes five chainring spacers to distance the original bolts. Double chainring crank sets, should definitely mount the required chainring in the outer most position.

Threaded Sprockets (no longer produced):

Sprocket sizes 15 art. 8220, 16 art. 8221 and 17 art. 8222 are all designed as reversible sprockets.

The retrofit versions of the Rohloff SPEEDHUB 500/14 are pre-fitted with a 16 tooth sprocket. 15 and 17 tooth reversible sprockets are available to purchase separately. Hereby, an individual sprocket/chain ring combination can be applied (see 'Technical data' - 'chain rings'). The 15, 16 and 17 tooth sprockets are all reversible, and therefore, can be flipped over once worn, so that the unused tooth edge can be used. A special Rohloff sprocket removal tool (Art.#8508) is required for removing and re-mounting these components.

13 tooth Threaded Sprocket (Art.#8219)

When unmounting a Rohloff SPEEDHUB 500/14 in a small wheeled bicycle (e.g. 20", folding bicycles and recumbents) the special 13 tooth sprocket will probably be required. This utilizes a different chain line (59mm instead of 54mm) and is not reversible. When using a Rohloff chain tensioner on frames with dropouts thinner than 7mm, the longer chain tensioner mounting bolt (Art.#8255) should be used - this must be ordered separately. A special Rohloff sprocket removal tool (Art.#8508) is required for removing and re-mounting these components.

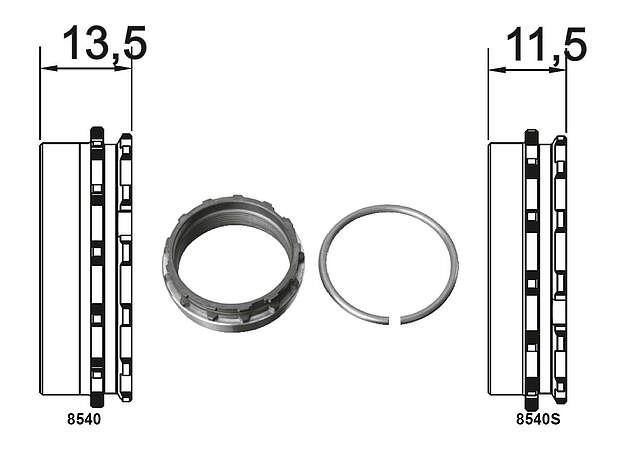

Splined Carrier & Splined Sprockets (13-19 + 21 tooth):

The Splined Carrier and Splined Sprockets replace the original threaded sprockets. This upgrade shifts the chainline a further 3mm outboard so may require the use of a longer chain tensioner mounting bolt and distancing washers (if applicable) depending upon dropout/derailleur hanger thickness. Upgrading to Splined Sprocket use is possible retrospectively to all SPEEDHUBs once the Splined Carrier (Art.Nr. 8540) is mounted.

A few select special applications may be unable to utilize this wider chainline (e.g. special chain-case, chain through frame tubing, collision with rear triangle tubing etc.) so for these rare cases, we have a special, slim splined carrier (Splined Carrier S (Art.#8540S)). This carrier is exclusively for use with splined sprockets of 15 teeth or over. It is not compatible with 13 or 14 tooth splined sprockets!

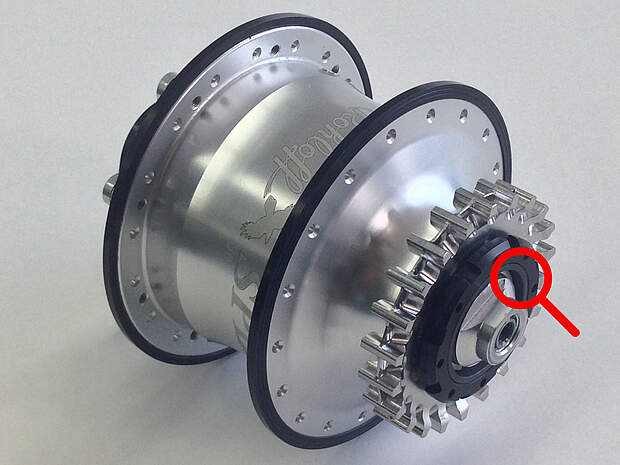

Splined Carrier L (with Lock-Ring) for Gates Carbon Drive / SPEEDHUB splined sprockets:

The Rohloff Splined Carrier 'L' (Art.#8540L) has been specially developed for the use with Carbon Drive splined sprockets and will be available as an addition to the ‘regular’ (Art.#8540) and ‘slim’ (Art.#8540S), tool-free Rohloff Splined Carriers.

The main difference between this new Splined Carrier 'L' and the other two existing Splined Carriers, is that the ‚L‘ version secures the sprocket in place using a Lock-Ring which will require the use of a face-wrench, hook-wrench or the special Rohloff Lock-Ring tool (Art.#8518) to secure the sprocket in place.

The Lock-Ring should be secured with a tightening torque of 30 Nm.

The Lock-Ring ensures that Carbon Drive sprockets are secured laterally to the Splined Carrier' L' and thus eliminates any micro-movement of the Carbon Drive splined sprockets created by the pre-tension of the Carbon Drive belt.

Compatibility of Splined Carrier 'L' with Rohloff Splined Sprockets:

- 13 & 14 tooth Rohloff Splined Sprockets: - Not compatible!

- 15 - 19 & 21 tooth Rohloff Splined Sprockets: - Compatible!

We recommend use of the regular splined carriers (Art.# 8540 & Art.# 8540S) for chain use due to the advantages of tool-free sprocket mounting/removal.

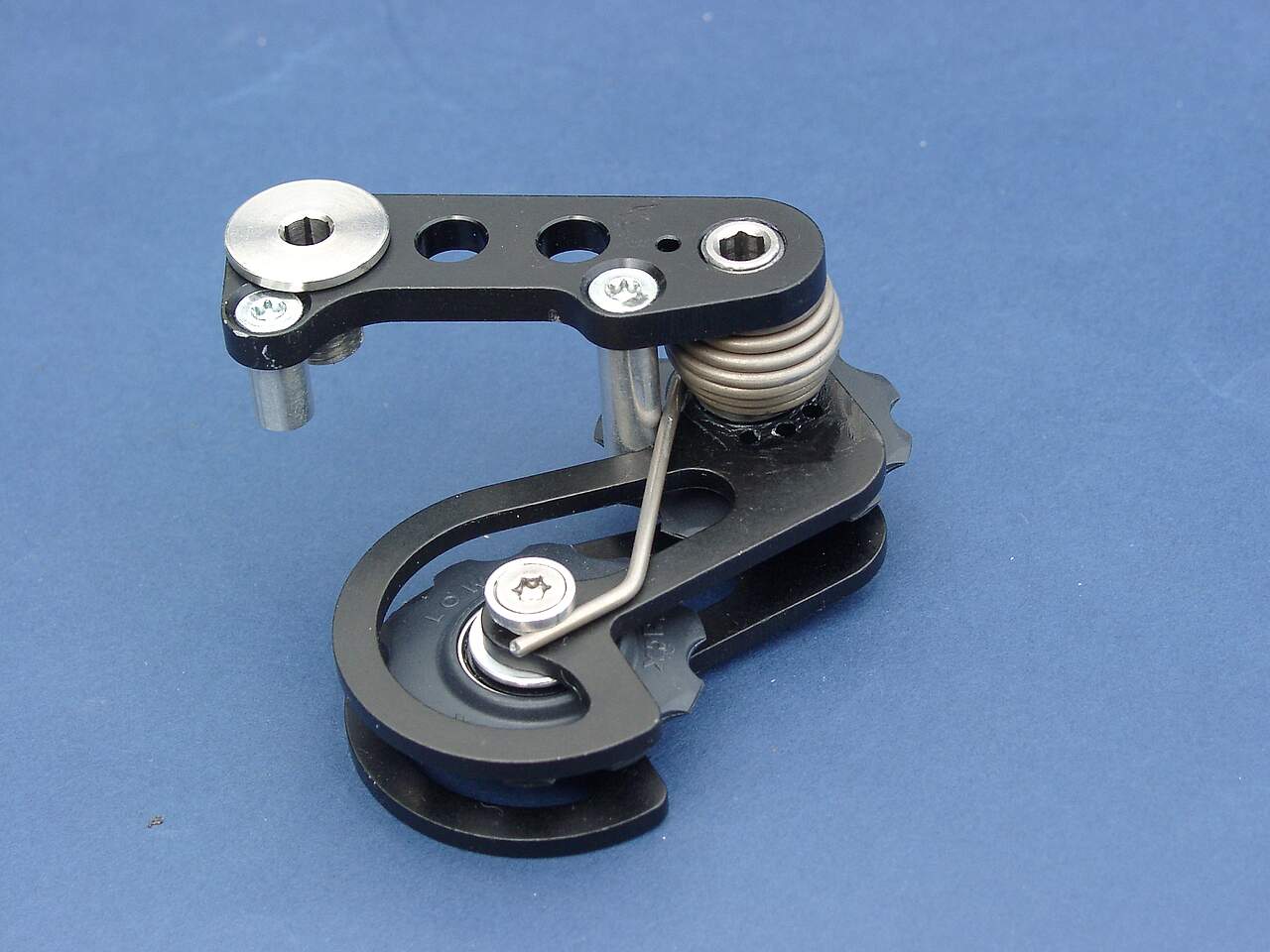

Rohloff Chain Tensioner (Art.#8250)

Mounting a chain tensioner is necessary on frame types A, C, D, E and G (see SPEEDHUB finder - 'frame types'), when an eccentric Bottom Bracket is not integrated into the frame design. This is necessary because there is no other possibility to re-tension the chain as the chain wears. The chain tensioner equally as necessary on frames with rear suspension, this reason for this being that the distance between the chain ring and sprocket varies as the suspension element moves the rear triangle of the frame. The span capacity of the Rohloff chain tensioner is 10 links or 20 teeth. Because a slack chain can allow sideways chain movement, we recommend that the Rohloff chain guide also be fitted up front if the bicycle is used in off-road, uneven conditions.

Rohloff DH Chain Tensioner (Art.#8245)

The Rohloff DH chain tensioner is specially designed for extreme downhill use. As opposed to the regular Rohloff chain tensioner it has a shorter link arm that is hindered from moving on the mounting point. This keeps the chain securely in position against the sprocket, guaranteeing a positive run from the chain onto the sprocket even under extreme riding conditions. The Rohloff DH chain tensioner should be used in conjunction with a chain guide up front.

Rohloff chain guide CC (Art.#8290) no longer produced

The Rohloff chain guide CC prevents the chain from jumping off the chain ring on all bicycles fitted with a chain tensioner. The Rohloff chain guide is adjustable to fit with a range of different chain lines (distance between chain ring and frame center) between 52mm and 62mm. A chain tensioner alone is not sufficient to prevent the chain jumping off chain rings under extreme riding conditions.

Rohloff DH chain guide (Art.#8291) no longer produced

The Rohloff DH chain guide is specially designed for extreme downhill use. It completely eliminates the ability for the chain to fall off the rear sprocket and onto the hub casing.

Can I use any type of shifter with the SPEEDHUB 500/14?

Unfortunately not. Only the Rohloff Twist Shifters can be used.

The Rohloff twist shifter is able to pull the two shifter cables in either direction. As the shift indexing mechanism resides inside the hub, the shifter requires no separate indexing mechanism itself.

There are no other alternative style shifters available with these features.

Other Twist Shifters available:

Rewel Shifter

Tune Rolff I and Rolff II shifter

Hebie Chainglider for SPEEDHUB 500/14 (Typ 350 SPEEDHUB)

With the use/mounting of a Hebie Chainglider SPEEDHUB (typ 350) one has to pay attention that parts made of plastic are unable to scratch on the surface of the hub case!

With the first series of Chaingliders scratching marks occasionally appeared on the hub case by the grinding touch of the Chainglider's rear side. In October 2006 the rear part has been modified to prevent a possible abrasion. Scratches on the surface cannot diminish the stability of the SPEEDHUB case - they' re just ugly.

Now, old rear parts of the Chainglider must be exchanged to new versions.

Exchange at your bicycle dealer only!

Permitted is the use of the Chainglider with 15, 16 or 17 tooth sprockets in combination with a 42 tooth chain wheel (Typ 350-42) or a 44 tooth chain wheel (Typ 350-44). The use of a 13, 14 tooth sprocket or combination with splined carrier L (Lock-Ring) with the Hebie Chainglider is not permitted due to technical reasons!

While adjusting the chain tension, please pay attention to an abrasive-free sit of the chain at the hub case and check it regularly.

Technical Information:

While riding the bike dirt particles might easily stick in the soft plastic, which can turn into a hard, abrasive surface after a while. Due to this, deep grinding grooves can emerge. In the extreme, the hub case might has to be exchanged.

A grinding-through of the hub case is not very likely, but technically possible.

Is it possible to mount the Rohloff SPEEDHUB 500/14 in a combination with a thru-axle?

The Rohloff SPEEDHUB 500/14 is constructed around a 135mm O.L.D. and designed exclusively to work in 135mm spaced bicycle frames. The new SPEEDHUB XL, introduced in 2014, is designed exclusively to work in 170mm spaced bicycle frames although as of 2016, this can be externally adapted to work in 190mm spaced frames.

135mm SPEEDHUBs and 170mm SPEEDHUB XL units are available with a choice of hollow, 10mm axle (for standard quick release skewers) or a threaded (M10x1) solid axle. These hubs are not compatible with any thru-axle standards available at time of press.

The reason thru axle versions were previously not available is simple ... the SPEEHDUB is constructed around its axle which houses the entire shifting and indexing mechanism. Increasing axle size would increase other component size and thus weight resulting in an incredibly inefficient and unmarketable product.

2016 will see the introduction of the new SPEEDHUB A12 variants. These hubs offer the ability adapt the regular SPEEDHUB construction so it can be mounted into a bicycle frame designed for 12mm thru-axles. The A12 variants will be available with a choice of 142mm, 148mm boost, 177mm or 197mm O.L.D.

The 12mm axle supplied with each frame can be discarded and replaced with a special set of Rohloff adapter sleeves. Through these sleeves, M7 bolts will be inserted and threaded into the internally tapped A12 SPEEDHUB axle to secure the hub in position.

These adapter sleeves (available for DT, Maxle, Syntace and Shimano e-thru axle systems) are available in different configurations to ensure we have a compatible hub for the majority of frames out there.

As always it is imperative that the mounting information is correctly adhered to in order to ensure the safe, problem-free integration of the transmission.

Chain guard in conjunction with the Rohloff SPEEDHUB 500/14

In theory, all chain guards could be used with the Rohloff SPEEDHUB 500/14. They must however be checked, that they fit to the frame in question.

Which chain guard is correct for the frame however, is impossible for us to say - there are simply too many different combinations of type, mounting method, and frame on the market.

The firm NÖLL offers a chain guard especially designed for the Rohloff SPEEDHUB 500/14. Further information on this can be found on the web under:www.noell-fahrradbau.de

The firm UTOPIA also offers a special chain guard exclusively designed for the Rohloff SPEEDHUB 500/14.

Further information on this can be found on the web under:www.utopia-fahrrad.de

Another Chainguard is available from Patria

Further information on this can be found on the web under:www.patria.net

Idworx also have a Chainguard available

Further information on this can be found on the web under:www.idworx-bikes.de

Monkey Bone - IS-Postmount brake adapter

The Monkey Bone offers a simple method of anchoring the axle of the Rohloff SPEEDHUB 500/14 to a frame through the disc brake mount. In order to use the Monkey Bone, your SPEEDHUB 500/14 will need an OEM2 axle plate, your frame must have an International Standard disc brake interface, and your disc brake caliper must have a Postmount interface. The Monkey Bone is not compatible with IS direct-mount disc brake calipers or frames with Postmount disc brake interface.

Assembly instruction Monkey Bone for 160/180mm discbrake (English):

Required Tools:

• 5mm Allen wrench

• Torque wrench

• T20 Torx wrench

Required Parts:

• Frame with IS51 disc mount interface (seatstay)

• Disc brake caliper with Postmount interface

• Rohloff SPEEDHUB 500/15 with OEM2 axle plate

• Monkey Bone

• 2x M6x16 bolts (sold separately; typically included with disc brake caliper)

• 2x M6x18-20 bolts (sold separately; often included with disc brake caliper)

Installation Instructions:

1. Ensure that you have the Monkey Bone that is appropriate for your disc rotor diameter (160mm or 180mm; 203mm rotors can be used with 180mm Monkey Bone and spacers (sold separately))2. Attach the Monkey Bone to the frame using two M6x18-20 bolts. Ensure that slot for OEM2 axle plate faces the dropout. Tighten bolts to a torque of 6 N-m/51 in-lbs.3. Connect disc brake caliper to Monkey Bone using two M6x16 bolts. Leave bolts loose enough that caliper can slide side to side.4. Install wheel into dropout taking care to align slot in end of OEM2 axle plate with cutout in Monkey Bone and disc rotor between brake pads.5. Check position of EX shift arm with OEM2 axle plate engaged with slot in Monkey Bone; reposition axle plate as needed for desired cable routing using T20 Torx wrench (see Rohloff owners manual). Tighten axle plate screws to a torque of 3N-m/25 in-lbs.6. Fully seat axle in dropout before tightening quick-release lever or axle nuts. Threaded axle nut torque: 35 N-m/310 in-lbs; Pitlock or bolt-on skewer torque: 7 N-m/60 in-lbs.7. Follow brake manufacturer’s recommendation for setting brake caliper position. Tighten brake caliper bolts to a torque of 6 N-m/51 in-lbs.CAUTION: Use of the Monkey Bone with some frame geometry can result in the wheel being pulled out of the dropout while pedalling due to the forces exerted by the Rohloff SPEEDHUB 500/14 onto the frame. When the anchoring point of the OEM2 axle plate is located in front of a line parallel to the dropout slot, there is a component of the reaction force in the lowest gears that tends to push the axle down and out of the slot. Per Rohloff’s recommendation, the Monkey Bone and OEM2 axle plate combination are not recommended for use on frames with such geometry (see page 30 of the Rohloff owner’s manual for more info). Use of the Monkey Bone and OEM2 axle plate is entirely at the user’s own risk. The forces applied to the disc brake mount by the Rohloff SPEEDHUB 500/14 can damage some frames. Please contact your frame manufacturer to determine whether this setup is appropriate for your frame and whether it affects your frame warranty.

Files:

PITLOCK available for the Rohloff SPEEDHUB 500/14

The pitlock set M10 Rohloff mono is recommended for frames which incorporate dropouts that are thicker than 8mm and use a TS axle. For this you will require the appropriate Rohloff axle plate with a longer axle stud.

8228L TS OEM2 long

8233L TS Standard axle plate long

8235L TS OEM long

Frames that utilize dropouts thinner than 7mm can use the PITLOCK Securing Set M10 Rohloff dual for mounting. Make sure that the threads protrude the dropout slot far enough to mount the securing components.

Safety-catch for (slideable) rear bolted dropouts:

This new safety-catch is for bolt-on adjustable dropouts and is designed to prevent an easy removal of your rear wheel. Dispite having a PITLOCK securing the rear wheel, it is still possible that a thief may be able to steal the complete rear wheel simply by unbolting the not-protected rear dropouts. To prevent or to hinder this, it is now possible to mount this PIT- dropout security system.

All important information can be found on the homwpage of Pitlock!

Schlumpf Speed Drive, High Speed Drive, Mountain Drive

The Schlumpf Speed-drive works like two chainrings with a large difference in size.

With the additional transmisson ratio of 1:1.65 the gear ratio of the Rohloff SPEEDHUB 500/14, when used in conjunction with the Schlumpf Speed-drive, will be increased to 868%.

When fitting a Schlumpf transmission, please bear in mind that it is still important not to undercut the smallest permitted sprocket ratios (see 'sprocket ratios').

The Schlumpf Mountain Drive is not permitted for use in conjunction with the Rohloff SPEEDHUB 500/14.

The Schlumpf High Speed Drive (1:2.5) is not permitted for use with the Rohloff SPEEDHUB 500/14 due to its standard 27 tooth integreated chainring. A number of alternative chainring sizes are however available from schlumpf so as to not undercut our smallest permitted sprocket ratios.

For versions with compatible chainrings please contact schlumpf directly.

Authorized / Non-authorized third-party component integration

The Rohloff SPEEDHUB has been designed, tested and revised over many years, striving to produce world’s most durable bicycle transmission.

We feel we have achieved this target to date however, the SPEEDHUB is only as good as the components and accessories used in conjunction with it. As such, Rohloff closely monitor and test 3rd party developments that may be marketed as "SPEEDHUB compatible" or "suitable for SPEEDHUB use", so that we can confidently confirm their compatibility and safety, should SPEEDHUB customers wish to use these.

Not all 3rd party components will satisfy our high standards and unfortunately, many will be denied authorization for SPEEDHUB use. The safety of each and every SPEEDHUB rider is our #1 priority and we cannot authorize use with a 3rd party component, if we have any safety concerns regarding the combination.

Aside form technical and safety related issues, 3rd party components will also be refused authorizion if we feel they are detrimental to the riding experience which our customers expect from their SPEEDHUB transmission.

Those components which are authorized for use, will be listed in the “Tuning Parts” section of our website.

The Rohloff AG asks all customers to refrain from use of unauthorized 3rd party components. Use of such unauthorized components may hinder our ability to remote diagnose issues and they may result in partial loss of Rohloff product warranty and courtesy repair options. Repair costs and secondary costs remain the sole responsibility of the user themselves. Failure to acknowledge the lack of authorization omits the Rohloff AG from any liability for accidents or injuries incurred as a direct result from use of such 3rd party components.

Axle Plates and Dropouts

Horst link. Can the Rohloff SPEEDHUB 500/14 be built into a frame with a Horst link?

With this suspension principle, a joint is to be found directly in front of the dropout.

The chainstays and the dropouts do not form a sturdy structure.

In this case the long torque arm would disable potential for the rear swing arm to move.

This is obviously not the point of a full suspention frame.

The Rohloff SPEEDHUB 500/14 can therefore only be used on a rear 4-link frame (with this Horst link) when mounted in conjunction with an OEM or an OEM2 axle plate.

Can the Rohloff SPEEDHUB 500/14 be used on a racing bike?

The Rohloff SPEEDHUB 500/14 was constructed as an alternative to derailleur gears for mountain, trekking and city bike use.

The information over derailleur gears from these areas (working efficiency, robusticity, weight and gear ratios) was taken to construct the Rohloff SPEEDHUB 500/14. The benefits were taken into concideration along with the known disadvantages (wear, maintenance and care work, constant adjustments etc.) that needed to be eliminated.

These problems are generally the same for all bicycle types. However, the factor of weight plays a much larger role in the racing bike field, the need for such a large overall range of gears is also not needed. Most riders choose to run a finer ratio (smaller gear increments), the problem of dirt is also not so problematic for the racing biker.

It is for these reasons that the Rohloff SPEEDHUB 500/14 was focused specifically for MTBs. You can of course mount the Rohloff SPEEDHUB 500/14 into a modern racing frame without any problems (as long as the frame spacing is 135mm). There are no current plans on building a special lightweight SPEEDHUB version for racing frames which for a frame spacing of 130mm.

Axle type change between TS, CC & A12.

Changing the axle from CC, TS or A12 to a different type is retrospectively not possible. The complex SPEEDHUB gearbox is build around and calibrated for each respective axle so swapping this out would require other components to be recalibrated and various other gears to be swapped in order to remain compatible. This is not a cost effective solution and as such will not be offered.

New OEM2 option via luggage rack mount with use of M5 adapter

Many bicycle frames already incorporate a 5mm drilled and tapped hole in the rear dropouts. This hole is primarily designed to accommodate the mounting bolt for luggage racks and fender mounts. If this hole happens to be located as illustrated in the diagram below, then an M5 bolt (tensile strength = 8.8) can be threaded into this hole (and through luggage rack mount etc) from the outside dropout face and then secured on the inside dropout face with our new M5 adapter. It is this M5 adapter that the standard OEM2 axleplate then grips around to anchor SPEEDHUB torque securely to the frame.

The position of this 5mm hole is important however. The hole needs to be located behind an imaginary vertical line through the hub axle. If thehols is located in front of this line, there is a risk that the axleplate will actually lever the wheel out of teh dropout and as such obviously cannot be used for SPEEDHUB torque support.

https://www.rohloff.de/en/service/handbook/speedhub/assembly/torque-anchoring#c22622

The combination of M5 adapter (# 8552) with M5 screw is not approved for use on a tandem or e-bike (max. > 250W nominal power / max. > 800W peak power).

Primary Transmission - Chain, Belt drive systems

Chain - Which chain with a Rohloff SPEEDHUB 500/14 sprocket?

1/2"x3/32" 8, 9 and 10-speed chains are suitable.

8-speed chains are preferable because they have a lower elastic stretch than 9-speed and 10-speed chains and therefore wear less on the sprockets (2mm) and chainrings.

Bicycle chains (1/2"x1/8") are compatible with SPEEDHUB 500/14 sprockets but are not recommended.

When using a 13, 15 screw sprocket, care must be taken that the maximum chain height of 8.5mm is not exceeded. Otherwise there will be contact between the chain and the hub housing or with the 13 mm screw sprocket the chain will run into the base of the component. This leads to grinding marks and even damage to the hub housing. When driving (freewheeling and pedaling) there is stiffness and noise in all gears.

When using a 13, 14, 15 sprocket, please use the Splined Carrier 8540 and adhere to the maximum chain height of 8.5mm.

Despite their larger width, these chains have lower strength and lower wear resistance. They are therefore not recommended as a drive chain for the Rohloff SPEEDHUB 500/14. Please be sure to check whether there is sufficient distance between the hub housing and the chain.

1/2"x1/8" chains are NOT compatible with the various Rohloff chain tensions.

Chainline

The Rohloff SPEEDHUB 500/14 requires a chainline of 54mm and with splined sprocket of 57mm. On bikes with three-ring cranksets, the middle chainring sits on a chainline of 47.5mm (measured from the frame center). The largest chainring has a chainline of 54mm.

On most MTB and Trekking bike cranksets, the largest chainring and bottom bracket can normally be reused in conjunction with the Rohloff SPEEDHUB 500/14.

Current Rohloff SPEEDHUB 500/14 models are equipped with our new splined carrier sprocket system which creates a 57mm chainline as opposed to the old 15, 16 & 17 tooth threaded sprockets which used a 54mm chainline. The center chainring position of a triple crankset is 47.5mm which places the outermost chainring in this optimal position for this new, wider chainline.

When converting MTBs and Trekking bikes for SPEEDHUB use, it is usually possible to simply remove all but the outermost chainring, and continue running the current crankset and BB.

- Art.#8540 Carrier (13.5mm deep) = compatible with 13-14-15-16-17-18-19-21 tooth sprockets = 57mm chainline

- Art.#8540s Carrier slim (11.5mm deep) = compatible with 15-16-17-18-19-21 tooth sprockets = 55mm chainline

Use of the the Carbon Drive system with the standard lock-ring splined carrier (Art.#8540L) will create a belt-line of 55 mm (+/-1mm).

Chainline offset Info:

Use of a SPEEDHUB on a frame with the average chainstay length of 450mm results in:

- 1° chainline offset / approximately 8mm

- 0.5° chainline offset / approximately 4mm

This is technically is harmless and unproblematic for the function.

Generally the goal is to create a chainline with as little offset as possible.

To extend the lifespan of all sprockets, it is also generally advised to use as many teeth as possible to achieve the desired transmission ratio.

Note:

Use of modern 12 and 13 speed derailleur cassettes will create a chainline offset of approximately 5-6° which translates to approximately 40-45mm.

Smallest permittable sprocket ratios

The sprocket ratio on the Rohloff SPEEDHUB 500/14 (e.g. 42:16) converts the slow rotational speed at the crank into a fast rotational speed at the sprocket and thus reduces the input torque for the Rohloff SPEEDHUB 500/14 simultaneously.

To prevent overstraining the hub, a minimum sprocket ratio of 1.9 must be used. With the available sprockets these minumum possible sprocket ratios are:

chainring/sprocket: ~40:21, ~36:19, ~34:18, ~32:17, ~30:16, ~28:15 (ratio 1.9)

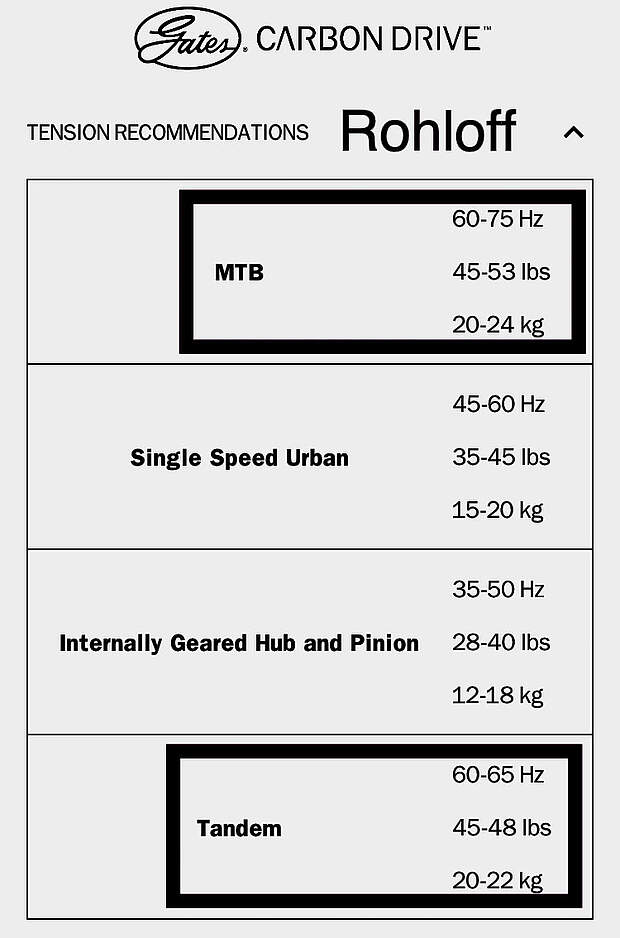

belt sprocket: 39:19, 39:20, 42:22, 46:24 (ratio 1.9).

This resembles a derailleur transmission of 20:40. Larger chainrings can be used without exceptions.

Attention!

If mounting the SPEEDHUB 500/14 on a tandemor if the rider weighs over 100kg, the following sprocket ratios are the lowest permitted for use:

chainring/sprocket: ~53:21, ~48:19, ~45:18, ~42:17, ~40:16, ~38:15 (ratio 2.5).

belt sprockets: 46:19, 50:20, 55:22, 60:24 (ratio 2.5).

The use of all 13 and 14 tooth splined sprockets is only authorized when used with a minimum primary transmission factor of 3.0 – regardless of application area.

Gates Carbon Drive system is noisy

It is possible that the belt will produce operational noises, when rubbing against the center-track. This can occur due to incorrect belt-line, incorrect wheel alignment or component wear level. Spraying water onto the belt may eliminate the noise temporarily however a permanent solution will only be attained via correction of the belt line and/or wheel alignment, or the replacement of worn components.

A further cause of operational noise is a loose carrier lock-nut. Should your lock-nut come loose, then apply a small drop of thread sealant to the carrier thread before tightening the lock-nut to the correct torque.

Occasionally, noises are heard after riding in dirty conditions - especially when mountain biking through wet, sandy conditions whereby the sand then adheres to the belt teeth. In such a case, a quick rinse down with a garden hose will usually clear the belt of this sand and eliminate the noises. In select cases however, the sand particles will be embedded into the belt and cause the system to squeak as the belt with hard sand particles, rubs over the metal sprockets. If the noise persists after rinsing with water, then the remedy is as follows: spray the belt again with water and wait for this to dry off. Now apply a thin coating of silicone spray to the belt teeth. This dries immediately and accelerates the speed at which sand particles are then shed from the belt. This has no negative effect upon the life-expectancy of the Gates Carbon Drive components. Gates recommend the use of this product.

Ensure the Splined Carrier L (with Lock-Ring) Art. 8540L is always used in conjunction with Carbon Drive splined Rohloff sprockets. Pay close attention to the mounting instructions (30Nm do not use screw locking agents), to avoid additional operational noises!

![[Translate to en:] Gates Carbon Drive](/fileadmin/_processed_/d/b/csm_gates_rohloff_41f1895e1c.png)

Maximum chain height when using a 13, 14 and 15 sprocket

When using a 13, 15 screw sprocket, care must be taken that the maximum chain height of 8.5mm is not exceeded. Otherwise there will be contact between the chain and the hub housing or with the 13 mm screw sprocket the chain will run into the base of the component. This leads to grinding marks and even damage to the hub housing. When driving (freewheeling and pedaling) there is stiffness and noise in all gears.

When using a 13, 14, 15 sprocket, please use the Splined Carrier 8540 and adhere to the maximum chain height of 8.5mm.

When using a 15 sprocket with the Splined Carried S 8540S, please use a derailleur chain with a maximum chain height of 8.5mm and check the clearance between the chain and the housing.

High-quality and current gear chains generally adhere to the maximum chain height. BMX, single speed and hub gear chains etc. often exceed the stated height.

Crank rotation whilst pushing

Should the bike be pushed, it is possible that the cranks could also start to rotate.

This occurs due to the hub seal automatically activating the sprocket.

A very light running bottom bracket with poor quality seals will make it much easier for the cranks to rotate.

A drop of Rohloff cleaning oil (Part No. 8402) through the holes in the sprocket onto the hub seal will reduce this acivating effect.

Wherever power is transmitted, friction is produced within the mechanical system. In general this friction is lost as heat and is referred to as power loss.

While observing gear systems, two different types of power losses can occur. These are power dependent and power independent losses. Power independent loss is e.g. friction within the seals. Whether the bike is being pushed, ridden downhill or ridden with extreme force upon the pedals uphill, the friction force within the seals remains the same. Here the friction losses vary according to the condition of the seals (smooth or rough surfaces) and, depending on the speed, are very small producing between 1W and 3W of power loss. This small power loss is enough to bring a free spinning wheel to a stop just after a few rotations, or it makes the cranks rotate while the bike is being pushed.

The power dependent losses work completely differently. Whilst pedalling, the friction loss is produced between the tooth flanks of the gears and all bearings in use. Each different gear system produces a different percentage of power loss depending upon the mechanical construction. If the working efficiency of a gear system remains at e.g. 95%, the remaining 5% of the transmitted power is lost through friction. So, if a rider is pedalling with100W of input power, the rear wheel will only transmit 95W of output power onto the road because of the 5W power loss. If the input power is increased to 300W, the power loss will rise accordingly to 15W.

Should the rider increase his tempo to a fast, high blood pressure sprint with 1000W of input power, 50W of will be lost through friction reducing the output power considerably. This example shows clearly how important a good working efficiency is. The input power given by the rider defines the amount of power loss. In the examples this could be 5W, 15W or 50W. Through special constructive developments like an increased number of teeth per gear and the choice of using roller bearings for the planetary gears, running the gearbox within an oil bath the extremely rigid construction of the overall gearbox etc, the working efficiency of the Rohloff SPEEDHUB 500/14 is brought up to 96% (for gears 1 to 7) and 98% (for gears 8 to 14).

This working efficiency is comparable to a derailleur gear system. Common seven speed gear hubs reach a working efficiency of approx. 90% (gear #1) and 98% (direct drive gear). Again we observe our test rider, now pedalling up a hill with 200W of input power. While using the Rohloff SPEEDHUB 500/14 or a derailleur gear system, he will lose approx. 4% of output power, or riding in gear #4 as this is comparable to the first gear of a seven-speed gear hub, which is 8W. With the same input power but using a seven-speed gear hub, our test rider will lose approx. 20W of output power. Adding approx. 2W of power loss caused by the seals for the Rohloff SPEEDHUB 500/14 would bring the overall loss of power with the Rohloff SPEEDHUB 500/14 up to 10W against 20W with the common seven-speed gear hub. Conclusion: Power independent losses like the friction of the seals will have the same effect as a lightly rubbing brake block. This brings a free spinning wheel to stop but is barely noticeable whilst riding. But it is easy to recognise on a bicycle repair stand.

On the contrary, power dependant losses mean that a particular percentage of the transferred power is lost and not so easy to be detected on a bicycle repair stand, because the measurement can only really be made with the bicycle being ridden with the appropriate measuring aids.

The Rohloff SPEEDHUB 500/14 has an extra fact to take into consideration.

While the pedals are rotated backwards, the sprocket is being forced to rotate backwards. Therefore, the planetary gear system also has to run in reverse. The sun gears, that are fixed to the axle for the particular gear that is currently selected (when the wheel is being driven forwards) now rotate with a ratchet function over the pawls. Additional to this, it is possible that this freewheeling situation can be carried out by the component numbers 14 upper and 19, or 19 and 26 on our explosion diagram. The method that is used to allow this is 100% dependant on which gear is currently selected.

It is therefore easy to see that if the pedals are rotated backwards it causes more friction in turn.

If the rear wheel is freewheeling forwards and the cranks refrain from rotating, the first two planetary gear systems (twin planetary gear carrier) remain motionless and the planetary gear system 3 rotates. The freewheel mechanism to enable this is to be found situated in the middle of the planet carrier 2. The flat-toothed components (numbers 14 lower, 37, 38 on our explosion diagram) allow this gear carrier to freewheel. Which of these parts are active all depends upon which gear is currently engaged (gear # 1-7 or gear # 8-14).

As opposed to a derailleur gear system, the backward rotation of the planetary gear mechanism is not comparable to that of a running freewheel on a derailleur gear system.

Why do i need a chain tensioner?

The derailleur gear system requires a different length chain depending on the gear selected. This is due to the different sizes of the sprockets in use. When smaller sprockets are in use, there is an section of chain too much that needs to be tensioned, the rear derailleur does this by also including the chain tensioner function.

With the Rohloff SPEEDHUB 500/14, only one sprocket combination is ever in use (e.g. 46/16 ).

It is only possible to shorten a bicycle chain in steps of one link at a time (1 link = 1 male and 1 female link). You will find that with most frames, the chain will still be a few mm too long. It is these few mm that leave the chain slack and can allow it the to spring off of the sprockets in some circumstances which of course would lead to a spontaneous loss of drive causing accidents and injury to the cyclist.

Therefore, on hardtail frames without an eccentric Bottom bracket which use vertical dropout slots achain tensionerwill always be needed. On such bicycles it is not possible to pull the wheel backwards in order to tension thechain.

Is it possible to use the Rohloff Chain tensioner also for other gearhubs or singleespeed ?

In principle yes, however the measurement from the dropout outside face to the sprocket center must be no less than 24mm!

Use of belt drive primary transmisison systems

A belt drive as a bicycle primary transmission can only fulfil its purpose when all technical requirements of both frame and belt are adhered to:

- The belt must be pre-tensioned in accordance with the manufacture’s literature.

The belt manufacturer must offer approved tools and provide instructions as to their correct use for accurately measuring and adjusting the belt tension. Correct belt tension is pure guess work without access to such tools. - The belt must be capable of coping with this pre-tension as well as withstanding the far higher tension applied to it during operation. This is typically only possible to date via use of continuous, integrated carbon strands.

- Bicycle frames used in conjunction with belt drive systems, must be constructed with suitable stiffness levels to reduce lateral flex and compression.

An unsuitable frame will temporarily deform under these operational forces, reducing the distance between front and rear sprockets, dropping belt tension accordingly. The necessary belt pre-tension can thus easily enter an inadmissible range. - Suitable tools must be available to permit the safe and correct mounting/removal of sprockets to a Rohloff SPEEDHUB unit.

- Some form of apparatus or design element must be available to the safe run of a belt onto the rear sprocket, eliminating the ability for a belt to spring over the sprocket due to tension loss. Components such as the “Snubber” from Carbon Drive do just this and thus hinder riders from experiencing drive loss. Designs of third party/individual solutions must be approved by Gates (with regards to Carbon Drive belt compatibility), and Rohloff (with regards to safety and function) prior to use. This is a necessary step to ensure the function and thus safety of the individual solution.

Insufficient belt pre-tension and/or inadequate technical belt attributes will, under high-force operation, lead to:

- Enlacement issues between belt and sprocket teeth which in turn cause undesired belt ratcheting over sprocket teeth. The results of which are drive loss and possible accidents/injuries for the rider.

Not only do these situations create a safety issue, but they will also damage the belt, increasing the risk of further accidents if not replaced.

The only belt drive system currently able to fulfill all the above mentioned criteria, and thus authorized by Rohloff for use with the SPEEDHUB 500/14 transmission, is “Carbon Drive“ system from Gates.

All other belt drive systems are unable to fulfill one, or more of the points listed and as such, their use in combination with a SPEEDHUB 500/14 transmission will void aspects of the SPEEDHUB product warranty.

E-14

Which manufacturers offer models with Rohloff E-14 and Bosch Smart System (BES3).

According to the current status, the following manufacturers will have models with E-14 and Bosch Smart System in their range:

https://www.velo-de-ville.com/de

https://www.boettcher-fahrraeder.de/

https://www.co-motion-cycles.de/

https://www.ebike-manufaktur.com/

We will continually update this list. In the bike finder you can see the profiles of the bikes provided to us by the manufacturers.

Is the Rohloff E-14 also available for alternative E-motors?

The E-14 gear mech is currently, at the time of press (March 2020), only available for new bicycles using the Bosch or Panasonic FIT eBike-System. The Active Line, Active Line Plus, Performance Line, Performance Line CX and Bosch Gen 4 are all compatible. Both the Intuvia, Nyon and Kiox displays will be supported.

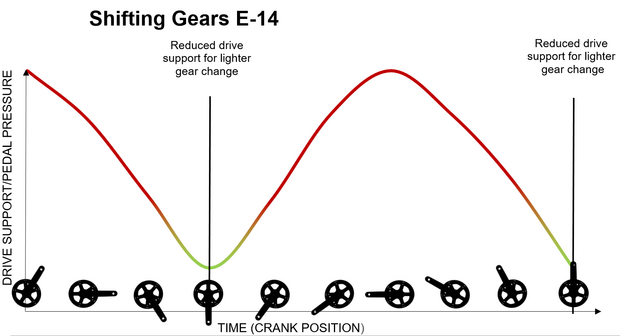

Shifting gears with the Rohloff E-14 gear-mech

Changing gear with the Rohloff SPEEDHUB 500/14 with pressure on the pedals is not necessary when being used appropriately. However due to the robust construction of the Rohloff SPEEDHUB 500/14 changing gear under pressure is possible and is not harmful to the hub. It is however possible that when changing gears under high pressure the hub could accidentally fall into a neutral gear, this is due to the coupling elements not seating correctly into the next elements and therefore rebounding back. If this occurs the rider could lose balance and crash. Changing gears under high pressure is at the riders own risk.

- optimal is a crank rotation of 50 – 80

- avoiding high loads on the cranks during shifting

- timely downshifting, e.g. before uphill gradients

Particulars:

If changing up and down slowly or under high pressure between the gears #7 and #8, it is possible to fall momentarily into gear #11 or #14.

Can I convert my existing Bosch or Panasonic FIT powered E-bike to run the Rohloff E-14 shifting system?

Dealers may be able to convert existing SPEEDHUB 500/14 equipped bicycles to run the E-14 shifting system however, the process and availability will differ from country to country and bicycle to bicycle.

STEP 1

Non-SPEEDHUB equipped eBikes using the Bosch system will be pre-programmed by the bicycle manufacturer, with a certain overall gear range. If the gear system is swapped for a SPEEDHUB with a larger gear range, then there is a risk that the Bosch system will believe it is being fooled into bypassing the boundaries of its type classification, will throw a fault code and shut down every time that one shifts a SPEEDHUB into a gear which falls outside this per-programmed range. The range will need to be checked using the Bosch diagnostic software, and if the range is not large enough (SPEEDHUB = 526%), then the Bosch dealer will first need to confirm whether they are willing and able to adjust this.

STEP 2

The current E-14 system requires the eBike motor software to be re-flashed with a special software container so that it can read and accept E-14 commands. Rohloff are unable to supply this software container file - motor manufgacturers in the EU are unwilling to due to possible liability issues involved with changing an important aspect of the drive-train and eBike type-approval and homogulation certificates.

Check with your bicycle, or eBike motor manufacturer about obtaining and installing this software prior to attempting a conversion. A converison is not possible without this software container file.

Can the Rohloff E-14 electronic shifting system be used on a bicycle without electric mid-motor support?

No, the Rohloff E-14 shifting system is currently only compatible with bicycles using the Bosch & Panasonic FIT eBike system. At this point in time, unfortunately not feasible as the current E-14 units require the power source and cock-pit of a Bosch or Panasonic FIT eBike system running the compatible software.

We are aware oft he demand for a non-Ebike dependent Rohloff E-14 version however the implementation of this will require further development and thus time.

We will inform you through our website and social media pages as soon as there is more information on these projects.

Will the Rohloff E-14 electronic shifting system be compatible with older Rohloff SPEEDHUB units?

Yes, the Rohloff E-14 is constructed to be backward compatible with all existing and older Rohloff SPEEDHUB 500/14 units. This option is unfortunately not feasible however, as the E-14 system require the motor software to be re-flashed with a special software container so that it can read and accept E-14 commands. Rohloff are unable to supply this software container file - this needs to be sourced from the eBike or emotor manufacturer.

Wheel/Spokes/Nipples

Rims for the Rohloff SPEEDHUB 500/14

The Rohloff SPEEDHUB 500/14 is only available with 32 or 36 spoke holes. XL and XXL versions are only available with 32 spoke holes.

Rohloff recommends the use of double or triple wall aluminum rims from known manufacturers. Should the rim use steel reinforced spoke eyelets, then these must measure a minimum diameter of 4.4mm.

Spokes used when lacing a SPEEDHUB wheel, must be tensioned to 1300N, so the minimum 1000N remians present after the tire is mounted and inflated.

Check the max. spoke tension limitations on the rim manufacturers website.

The large spoke hole diameter of the SPEEDHUB flange, means spokes enter rims at far more acute angles than on regular derailleur wheels. It is therefore worthwhile considering the use of rims where nipple holes are specially drilled to compensate for this flatter spoke angle. Such rims are available form:

Suitable, rims are available from:

www.ryde.nl

Rigida RYDE Andra 29/30/40/321

www.rad15.bike/en

Touring, eBike, Cargo Bike ...

An additional consideration should be made when selecting rims for XL/XXL SPEEDHUB verisons. This same nipple/spoke interface kink can arise in a lateral direction as well. As such, we recommend that rims used for these SPEEDHUB models, have a nipple-to-centerline offset of min. 12.5mm.

Click the appropriate link below for PDF documents of our ERD/Spoke length tables:

135mm, 142mm, 148mm (32 and 36 hole versions)

170mm, 177mm, 190mm, 197mm (32 hole only)

Oil and Lubrication

All-season oil and cleaning oil?

All forms of multi geared bicycle transmissions use a variety of movable parts regardless of whether they are derailleur or IGH style transmissions. These components need to be lubricated regularly to uphold the manufacturers warranty, to ensure easy operation and correct functionality as well as to protect these components against corrosion and premature wear.

The process of oiling chain drives is due to the principle of lubrication loss over time.

So far the following recommendation remains valid:

Derailleur gear systems:

The chain should be lubricated with a viscous chain lubricant at least every 500km. Lubrication is absolutely necessary following bicycle use through rainy conditions so that the oil can force any penetrated moisture out of the joints and thus prevent corrosion. Likewise the joints of the front and rear derailleurs should be lubricated with a drop of oil. Comprehensive hub maintenance should be completed every 3000km. The front and rear wheel hub and freewheel bearings should be checked and re-greased or replaced when necessary. The same applies to the jockey wheel bearings. The extent of component removal and preparation for these service tasks varies according to each application.

Standard IGH transmissions:

The chains of gear-hub drives are not subjected to such high stress situations as derailleur chains are. They are not required to cope with sideways movement, nor are they required to climb and fall from one sprocket to the next. With regards to this, these chains are not in need of such high maintenance. IGH chains only require lubrication approximately every 1000km - although on principle, these should still be re-lubricated following every rainy tour. Standard IGH transmissions are said to be low maintenance. The bearings of these IGHs are filled with grease, the teeth of the gearwheels are greased and the surfaces of the planet-bearings and ratchets are lubricated with a few drops of oil. With intensive use the oil of the planet-bearings is consumed and the grease is pushed out from the bearings. The same happens to the tooth flanks of the gearwheels. Grease is forced away from the tooth flanks and cannot fulfil its function of lubricating the gear mechanism. To prevent the transmission from running dry, the hub should be stripped and re-greased at least every 4000km in order to ensure a long life. As above, the extent of component removal and preparation for these service tasks varies according to each application.

Rohloff SPEEDHUB 500/14:

Similar to an automotive transmission, the Rohloff SPEEDHUB 500/14 uses a sealed oil-bath lubrication. In the SPEEDHUB case, a shot-glass of special lubricant (12,5ml) is more than sufficient to lubricant the transmission for 1 year or 5000km of use. The movement of the gear system ensures that the oil is evenly dispersed around the hub coating all components with enough oil to guarantee smooth operation and durability. Because the Rohloff SPEEDHUB 500/14 can be ridden for so much longer than other bicycle transmissions without additional lubrication except for a few drops on its chain (see IGH above), it is referred to as being maintenance-free.

The Rohloff SPEEDHUB 500/14 is filled with an all-season oil. This oil copes with a large temperature range ensuring that expedition cyclists will not experience any oil viscosity related issues. In addition to lubricating the bearings and gear system of the SPEEDHUB, the oil also helps to dampen the noises created by the high efficiency straight-cut gears that are used. the noises created by the high efficiency straight-cut gears that are used.

Trouble Shooting

Wheel rotates with great resistance

Pushing the bicycle

The cranks can rotate when the bicycle is pushed along. This is due to the rear hub seal driving the sprocket onwards due to the contact between the two components. Poorly sealed and thus light running bottom brackets increase the ease with which the cranks can rotate. Add a drop of our SPEEDHUB cleaning oil (Art.#8402) through the holes of the rear sprocket and direrctly onto the hub seal to reduce this effect.

Excessive resitance on bikes without a chain-tensioner

Excessive rotating resistance on bikes with adjustable dropouts or eccentric bottom brackets can only be checked with the use of a mounting stand.

Shift into the highest gear (#14) and bring the wheel up to speed using the cranks. Now hold thecranks stationary and count the wheel rotations.

The wheel should now rotate at least 15 times.

Chain-tensioner jockey wheels are dry and don't rotate freely

Grease the axles of the chain tensioner and replace the jockey wheels if necessary. See Owners Manual "Service" 2. or "Repairs" 2.

Freespinning (after a gear change)

Gearbox oil too thick

- Carry out an oil change with an intensive rinsing,

see Owners Manual "Service" 1.

Riding the bike in temperatures below -15°C

- Rinse the SPEEDHUB intensively and fill with a mixture of 50% All Season Oil and 50% Cleaning Oil = 12.5ml.

see Owners Manual "Service" 1.

Other Causes:

The SPEEDHUB 500/14 axle is secured too tightly into the frame which could damage internal components.

- CC (quick-release) axles using a security skewer (Pitlock / Pinhead / Allen Key) = max. 7Nm.

- TS axle nuts (M10x1) = max. 35Nm

Oil drain screw is re-inserted too deep following an oil change. Now places pressure upon internal transmission components.

- Oil drain screw head must not rest deeper than flush with the outside hub-shell material.

Check that both freewheel springs are present and seated correctly see Owners Manual "Repairs" 1.1 and "Service" 5.3.

If chain, sprockets or jockey wheels of the chain tensioner are worn, then

the operational safety can no longer be guaranteed. Because of this, we are unable to excluded the possibility that the chain jumps off sprockets, especially under high pedal loads (up-hill). For this reason, it is vital that all other elements of the bicycle transmission are regularly inspected and replaced where necessary to ensure the safe use of the bicycle!

If the problem cannot be resolved, then bring your bicycle to your local dealer for further diagnosis.

Chain springs over the teeth of the sprocket

Chain defect (stiff chain link)

- Loosen up the stiff link or replace the chain

Worn sprocket or chain

- Rotate or replace the sprocket, replace the chain, see Handbook "Service" 3.

Not enough tension in the chain

- Correct the chain length/tension, see Handbook "Mounting" 5.3

Twist shifter will not turn through all 14 gears (14 gears = 13 clicks)

Shifter cables cut at the wrong length

Cut cables to the correct length:

- Internal gear mech, see Owners Manual "Mounting" 7.2.1

- External gear mech, see Owners Manual "Mounting" 7.3.1

Falsely altered cable adjusters:

- Alter the cable adjusters, see Owners Manual "Service" 2.

For external gear mech:

- Correctly align the hexagonal peg Hexagonal peg of the gear transfer box in an incorrect position, see Handbook "Riding with the SPEEDHUB 500/14" 3.2

Twist shifter does not turn freely

Cable tension is too high

- Reduce the shifter cable tension, see Owners Manual "Service" 2.

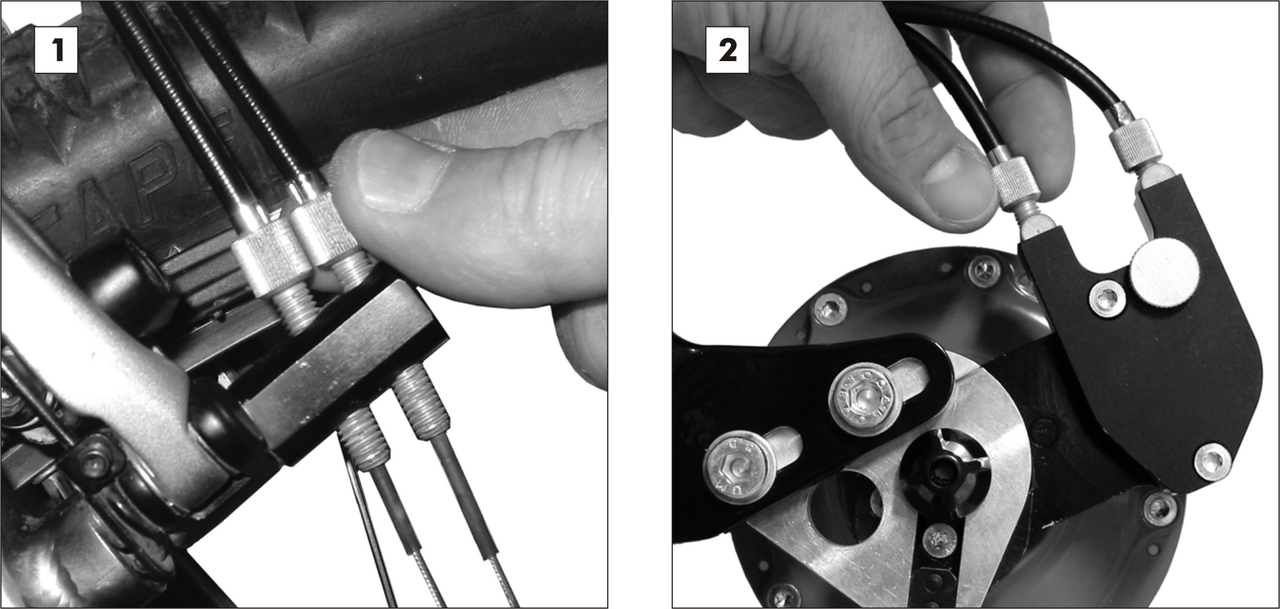

Check the internal gear mech:

- Open the bayonet connectors and (holding a cable in each hand) pull the cables in turn.

- They run smoothly, see points 2 - 6.

- They do not run smoothly, see point 7.

Check the external gear mech:

- Select gear #14. Remove the cable box just enough so that the twist shifter can be turned without force and the cables keep their normal routing bends. Turn the twist shifter back and forth.

- It does not turn smoothly, see points 2 to 6.

- It turns smoothly, see point 8.

- Shifter cables worn, dirty or damaged

- Incorrect shifter cables fitted (not orginal Rohloff)

- Cable routing has too many bends or kinks

- Inner nylon liners have penetrated into the twist shifter or the cable box (due to a false fitment)

Fit new shifter cables:

- Internal gear mech, see Owners Manual "Mounting" 7.2

- External gear mech, see Owners Manual "Service" 2.

Twist shifter rubs against the grip itself

- Leave a small gap between the twist shifter and the grip or insert a teflon washer between the two parts.

Hub cable broken and frayed

Check the shifter cables:

- Loosen the concertina tubes at the hub and pull them up towards the bayonet connectors. Check the condition of these cables in gear positions 1 and 14. If the hub cable is damaged, it will need replacing:

- One-piece axle ring, see Owners Manual "Repairs" 1.1

- Quick-change axle ring, see Owners Manual "Repairs" 1.2

Gear transfer box (external gear mech) is bent

- Replace the gear transfer box

- Removal, see Owners Manual "Repairs" 1.1

- Mounting, see Owners Manual "Service" 5.3

Hexagonal peg of the external gear mech does not turn freely (due to corrosion)

Checking:

- Place an 8mm wrench over the hexagonal peg of the external transfer box. When using the wrench to switch gears, the changing of gears must have a light and positive feel. If not, remove the external transfer box. Regrease the hexagonal peg and the sprockets C of the external shifter box (Owners Manual "Service" 5.3).

Twist shifter fails to turn in 0°C temperatures.

Water has penetrated into the twist shifter and has frozen

Remove the rubber grip. Clean, regrease this and when necessary replace the seal, see Owners Manual "Repairs" 3.

Water has penetrated into the shifter cables and has frozen

Replace the shifter cables and the nylon liners:

- Internal gear mech, see Owners Manual "Mounting" 7.2

- External gear mech, see Owners Manual "Mounting" 7.3

Water has penetrated into the cable box and has frozen

Open the cable box, clean this and replace the cable pulley with a little light grease.

Fitment, see Owners Manual "Mounting" 7.3.1

Low temperature/winter shifting issues

Problem-free cycling with a SPEEDHUB 500/14 through winter.

The SPEEDHUB is initially filled with 25ml of All Season Oil, which allows a problem-free operation down to approximately –15 °C (+/- 5°C).

If the bicycle however stands for long periods in the cold (e.g. outside over night with temperatures of down to –10°C), then the cooled gear-unit retains this temperature throughout the following day and this can lead to shifting problems.

These shifting problems are identified as freewheeling in the gear numbers 4,6,7 and 11,13,14 directly following a gear change.

To ensure a safe and problem-free operation throughout the winter months, the All Season Oil should therefore be thinned with 50% of our Cleaning Oil (total oil in gear-unit remains 12,5ml). The safe operation of the SPEEDHUB can now be guaranteed down to temperatures of approximately –30 °C.

To achieve this mixture, simply perform the annual oil change in two steps rather than one. Follow the normal oil change procedure up to the point where you extract the cleaning oil/all season oil mixture. Then, instead of inserting the new all season oil, simply re-insert the correct 12,5ml volume of this extracted mixture.

Use of this thinner oil mixture will have no negative effects on SPEEDHUB operation, even through the warmer summer months. The only disadvantage is that noises produced by the SPEEDHUB will appear louder in summer and the volume of sweat oil may increase slightly. For this reason, we advise extracting the oil mixture from the hub and inserting the new All Season Oil from your oil change kit, as soon as temperatures start to rise again.

A further proissue which may occur in the cold winter months is that the shifter cables could freeze - especially if the cables are routed under the bottom bracket. Any penetrated moisture tends to collect in this low point wher eit then freezes in temperatures below 0°C. This becomes immediately apprent when the twist shifter refuses to rotate. If this occurs, the water within the cables must be thawed and allowed to drain out from either end. Following this, the SPEEDHUB should once again operate undisturbed and correctly.

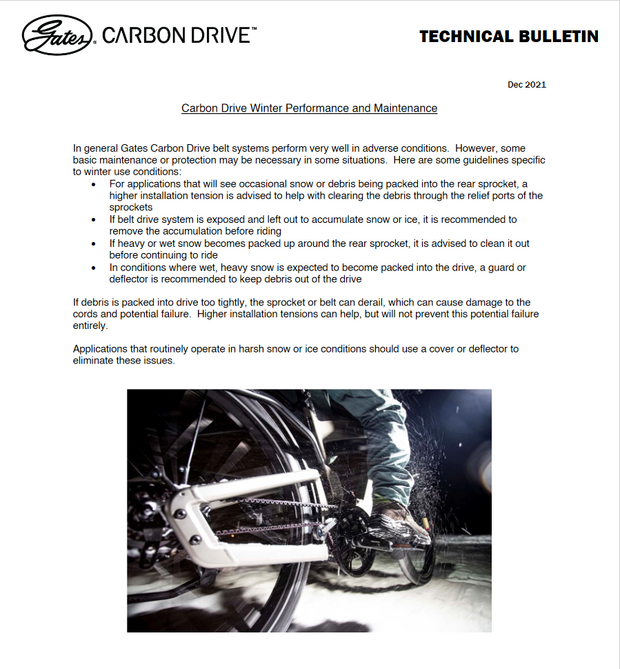

Gates Carbon Drive

In general Gates Carbon Drive belt systems perform very well in adverse conditions. However, some basic maintenance or protection may be necessary in some situations. Here are some guidelines specific to winter use conditions:

- For applications that will see occasional snow or debris being packed into the rear sprocket, a higher installation tension is advised to help with clearing the debris through the relief ports of the sprockets

- If belt drive system is exposed and left out to accumulate snow or ice, it is recommended to remove the accumulation before riding

- If heavy or wet snow becomes packed up around the rear sprocket, it is advised to clean it out before continuing to ride

- In conditions where wet, heavy snow is expected to become packed into the drive, a guard or deflector is recommended to keep debris out of the drive

If debris is packed into drive too tightly, the sprocket or belt can derail, which can cause damage to the cords and potential failure. Higher installation tensions can help, but will not prevent this potential failure entirely.

Applications that routinely operate in harsh snow or ice conditions should use a cover or deflector to eliminate these issues.

Gear Mech

Trigger Shifter

The Rohloff SPEEDHUB 500/14 was developed for use in competitive sport and leisure cycling sectors, enabling a direct, instant shift while stationary as well as in all riding situations.

As opposed to all other indexed bicycle transmission systems, the SPEEDHUB 500/14 shifts gears instantaneously rather than delayed as is commonplace with derailleur systems for example.

The positive indexed click of the shift can be heard and felt through the twist shifter, confirming the successfully completed shift process.

While shifting, different internal coupling elements are moved depending on the gear one shifts out of and into. The force upon the pedals puts these components under load and this load will change the amount of force required to shift gears. Whilst stationary, without feet on the pedals, the SPEEDHUB transmission is load-free and the twist shifter can be easily rotated from gear-to-gear. As soon as pressure is applied to the pedals however, the force required to rotate the twist shifter increases. Under heavy load, the force required to rotate the shifter can differ from gear-to-gear by up to 50%.

Use of a trigger style shifter will require that the force applied to overcome this pedal force, is created by the thumb/fingers alone. This will be incredibly difficult.

As opposed to a trigger style shifter, the thumb/finger used to shift will not be able to control this force as easily as a whole hand can with a twist shifter. The result would be numerous mis-shifts and over-shifting through the desired gear.

In addition, a further issue with trigger shifters is their inability to shift many gears at once - normally being limited by the leverage/lever throw, to just 2 or 3 gears s opposed to 8+ as with the Rohloff SPEEDHUB twist shifter. In order to capture the require volume of shifter cable, using this small lever throw, the trigger shifter would need to have a larger ratio which would result in excessive forces being required to operate said lever. Use of a traditional trigger style shifter is therefore unfortunately not possible.

Derailleur transmissions use trigger shifters which need only overcome the force of a small spring, independent of pedal force.

IGH systems using trigger style shifters are not designed for athletic, sportive cyclists and only pre-shift under load. The actual internal component movement takes place only after force is completely removed from the pedals. Furthermore, such systems normally only permit one gear to shift at a time.

As the requirements for the athletic cycling sector (multiple simultaneous gear shifts / direct shift feedback / shifting under load) cannot be attained with the use of a trigger style shifter, Rohloff have made a conscientious decision not to offer such a shifter for use with the SPEEDHUB 500/14 transmission.

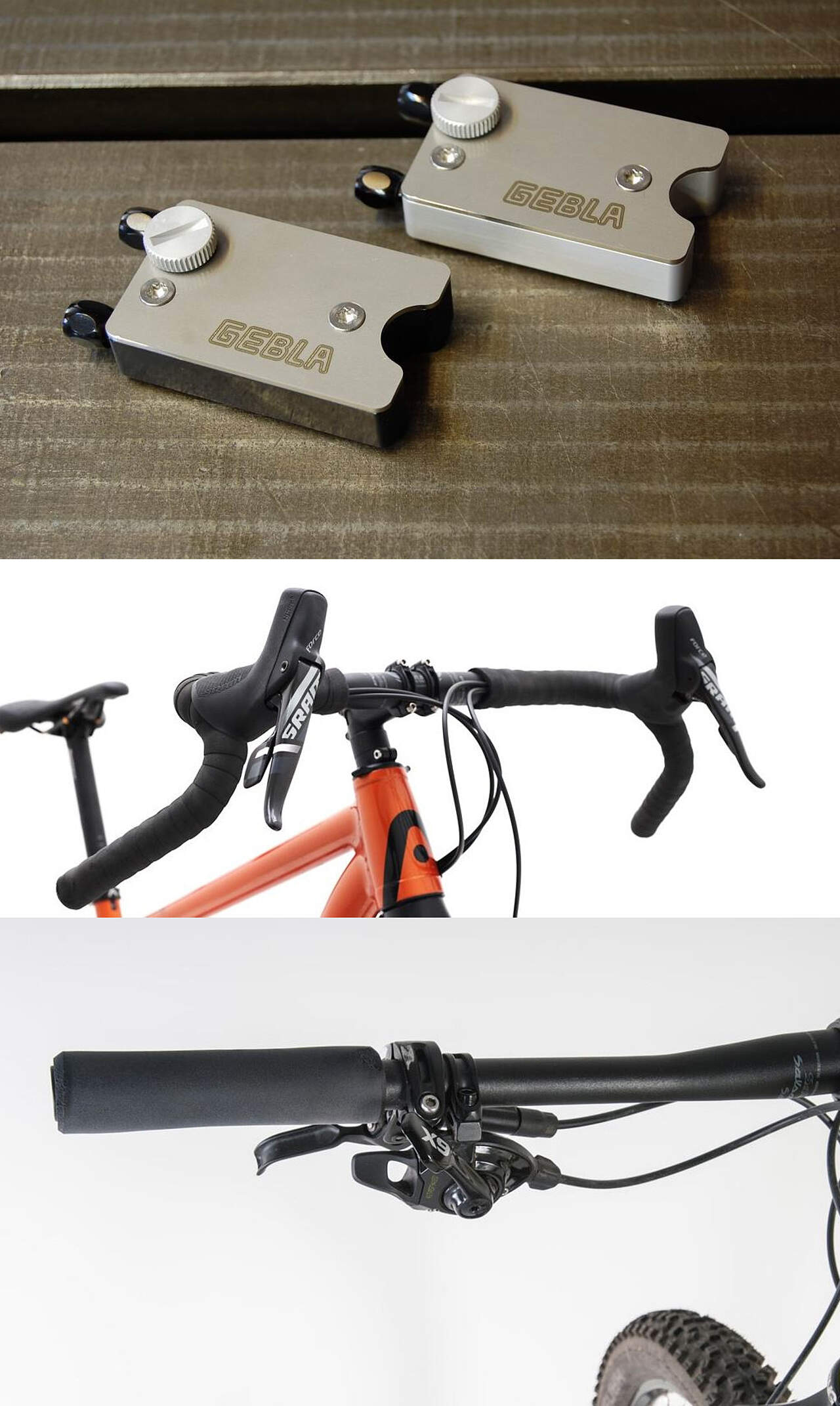

A few interesting solutions are available from third-paty manufacturrs - namely the 'Shift:R' from the company 'Cinq5'and the 'Rohbox' from the company 'Gebla'. Both alternatives replace the standard cable box of a SPEEDHUB EX Gear Mech, with their own mechanism.

<p> </p>

<p>The Co-Motion Rohloff Speedhub 14-speed shifter is designed to accommodate modern drop style road handlebars with a 31.8mm clamp size. These version conveniently mounts next to the stem, allowing full use of the handlebars while shifting from an upright riding position. Manufactured entirely in-house from 6061 aluminum, then hard anodized black, and laser etched for easy viewing. A clean and simple two piece design incorporates two O-rings to seal out the water and dust.</p>

<p>www.co-motion.com</p>

<p> </p>

<p>The Co-Motion Rohloff Speedhub 14-speed shifter is designed to accommodate modern drop style road handlebars with a 31.8mm clamp size. These version conveniently mounts next to the stem, allowing full use of the handlebars while shifting from an upright riding position. Manufactured entirely in-house from 6061 aluminum, then hard anodized black, and laser etched for easy viewing. A clean and simple two piece design incorporates two O-rings to seal out the water and dust.</p>

<p>www.co-motion.com</p>

Can the Rohloff twist shifter be mounted on racing bars?

The twist shifter for the Rohloff SPEEDHUB 500/14 can only be mounted upon straight or slightly bent bicycle handlebars with a diameter of 22.2mm (7/8").

Due to the shifters length of 60mm, it will not pass around the bends of racing bars or a Randonneur (racing bars with a lightly upward swung horizontal section).

Only special handlebars allow the twist shifter to be mounted at the top.

GeBla,

Norwid Fahrradbau GmbH,

www.norwid.de

Conversion of internal to an external gear mech

Bikes with a long torque arm and parts like mudguards, luggage carriers, kickstands make it almost impossible to place an external gear mech in a reasonable position.

If in doubt, please contact you bicycle dealer to resolve the issue directly with the object in question.

When using an OEM or OEM 2 axleplate, the mounting of an external gear mech is usually problem free when routing the cables via the chainstay.

A Video is available here: https://www.youtube.com/watch?v=WGNFZjavXcI

Disk Brakes

Conversion of a Rohloff SPEEDHUB 500/14 to a Disc Brake version

Every non-Disc version of theRohloff SPEEDHUB 500/14 can be converted for Disc Brake use. This converison requires the us of special tools to ensure the vital seal surfaces are not damaged by the process. As such, this can only be done at the Rohloff Service Department (Germany) or specially trained and equipped service partners and distributors (worldwide). The hub will therefore need to be shipped to one of these addresses for the converison to be completed.

A list of worldwide Distributors and Service Partners can be found online in the Worldwide section.

What is the thickness of our brake rotors, and when should they be replaced?

Each Rohloff brake rotor is lazer etched with the thickness and the wear limit.

2.3mm thick brake rotors (180mm/203mm/220mm) should be replaced once the thickness is reduced to 2.0mm.

2.0mm thick brake rotors (160mm/180mm/203mm) should be replaced once the thickness is reduced to 1.8mm.

1.8mm thick brake rotors (160mm/180mm/203mm) should be replaced once the thickness is reduced to 1.5mm.

Use of Rohloff brake rotors which exceed this limit, may overheat, warp and result in accidents and injuries. Regular checks are recommended.

Rohloff Brake Rotors are compatible with organic and sintered brake pads.

*Brake rotors wear quicker when using sintered pads.

The dust created by sintered pads can cause rusting of the steel components it lands on.

Maintenance and Service

Warranty: Rohloff SPEEDHUB 500/14

The Rohloff SPEEDHUB 500/14 has been constructed exclusively as a bicycle transmission.

Please, read the owners manual carefully before mounting and using the SPEEDHUB 500/14!

We guarantee a flawless and technically fault-free Rohloff SPEEDHUB 500/14 operation for a period of two years from the date of purchase. Excluded from this warranty are components subject to regular wear. Wearable components are those parts which are subjected to acceptable levels of wear while performing their function.

Wearable parts are: hub seals, jockey wheels on the chain tensioner, sprockets/carrier, shifter cables (internal gear mech), grip rubber of the twist shifter, break discs.

Non-wearable parts are: encapsulated gear box bathed in oil, hub case and twist shifter housing (external gear mech).

Any warranty extinguishes with damages, which are caused by: accident, using of brutal force, changes of built of any kind, incorrect mounting, incorrect use, inadequate maintenance, taking apart the gear box into its components.

All wearable parts mentioned above generally are subject to wear. The amount of wear depends on maintenance, service, how the product is used and cared for (running performance, pressure, rain and snow rides, dirt, salt, etc.) With regular cleaning and oiling, using the appropriate means, the life span can be elongated. A replacement is definitely recommended, when the wear limit is reached.

To guarantee the safe function, these parts must be replaced as soon as they are no longer capable of performing correctly. Therefore, it is necessary to have a service check and oil-change made, at the owner's expense, once a year or after 5.000km by a professional bike workshop, who is obligated to check over all the workings of your bike regularly and to replace worn parts.

The service check is to be documented on the service card by this professional bike workshop. In case the owner does not take much care with it, any claims for replacement extinguish, which can be traced back to a neglected service check. The regular service check in accordance with our instructions secures the warranty entitlement and keeps the high value of your Rohloff SPEEDHUB 500/14 in future.

Within the context of warranty, it remains our choice to perform replacement or any other work on the product.

Warranty claims must be processed through bicycle shops/workshops. Please bear in mind: submitted warranty claims will require the completed service card to be shipped with the hub, or the online registration form to have been completed and submitted. Processing of warranty claims for SPEEDHUBs purchased in complete bicycles, are still processed between the bicycle shop/work and Rohloff AG, bypassing OEM bicycle manufacturer for a faster, more efficient turnaround.

Rear wheel postage

Any problems with the Rohloff SPEEDHUB 500/14 should be discussed with your local bicycle workshop first. These bicycle mechanics are familar with typical bicycle issue sand should be able to locate whether an issue derives from the SPEEDHUB or possible another bicycle component.

Should your local bicycle workshop be confident that the issue is SPEEEDHUB related, they should submit a service form and we will then get in touch to exlain how best to proceed. The procedure will vary from country to country.

It is extremely important to ensure that the wheel is clean, the brake rotor is removed and that (where applicable) the external gear mechanism is well protected to avoid potential transport damage. The complete wheel must be properly and carefully packaged (we advise leaving the tire mounted to protect the rim). Repair costs for damage caused by the delivery firm, will fall to the sender.

Wearable parts

The wearable parts include, but are not limited to:

- Seals, Sealants, Gaskets

- Sprockets/Carrier (chain / belt)

- Jockey wheels of Chain Tensioner

- Shifter Cables

- Hub Cable of Internal Gear Mech

- Brake Rotors

- Rubber Grip of Twist Shifter

How quick these parts wear is down to how the product is used and cared for (pressure, dirt, weather and care). To guarantee the safe function, these parts must be replaced as soon as they are no longer capable of performing correctly. Let the function of your bicycle be regularly checked over by a professional bicycle workshop.

Maintenance and care of the Rohloff SPEEDHUB 500/14

The gears of the Rohloff SPEEDHUB 500/14 are protected from dust and harmfull moisture due to running in a service-free oil bath. The maintenance and care of the Rohloff system is limited to the following points: