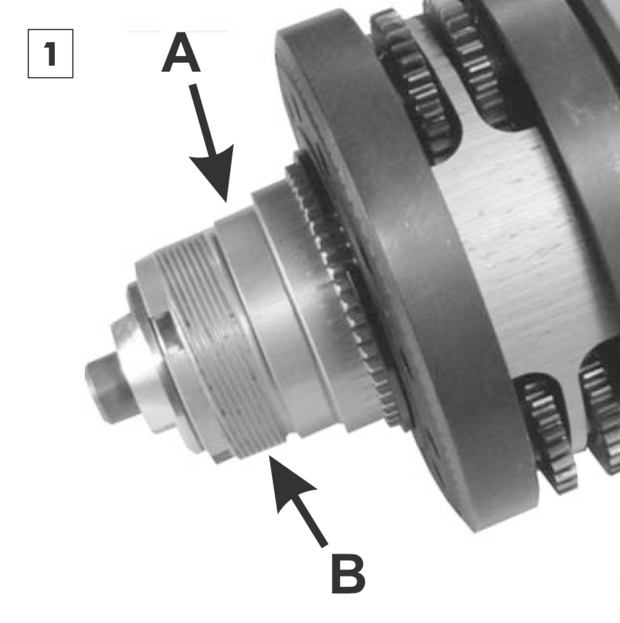

Gear-unit removal

The removal procedure must start with the the rinsing and draining of the oil from within the hub – see chapter Oil change. The drain screw must not be reused.

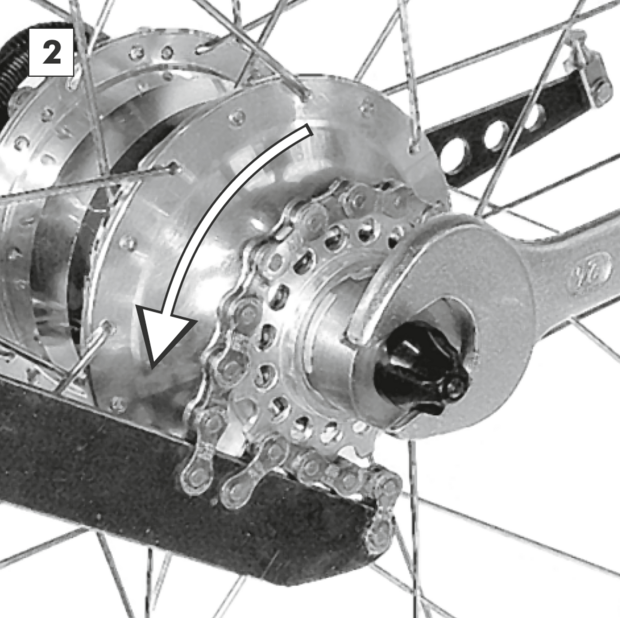

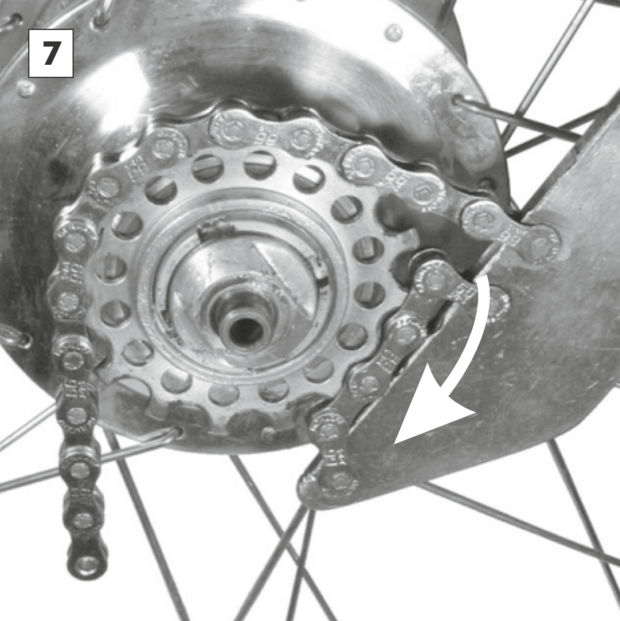

Remove the sprocket using a chain whip and the sprocket tool – see chapter Sprocket reversing/replacing.

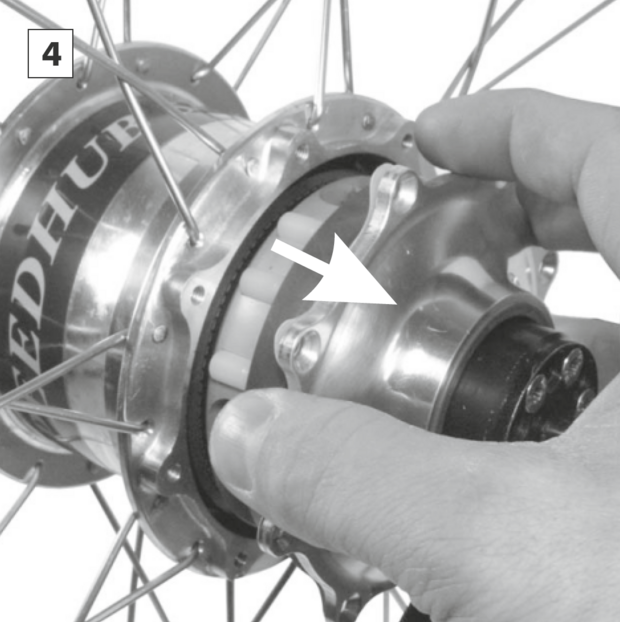

Gear-unit installation

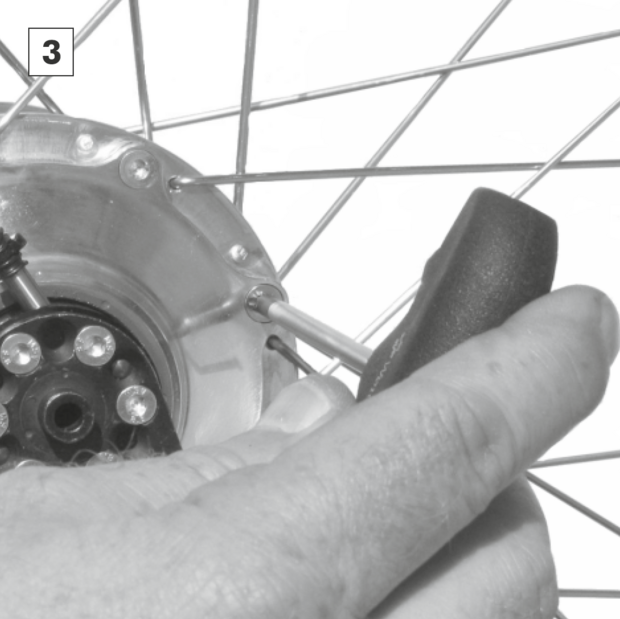

Refill the Rohloff SPEEDHUB 500/14 with 12,5ml of Rohloff SPEEDHUB OIL – see chapter Oil change. Refit a new drain screw (3mm allen key, tightening torque: 0.5Nm/4in.lbs.).