Introduction

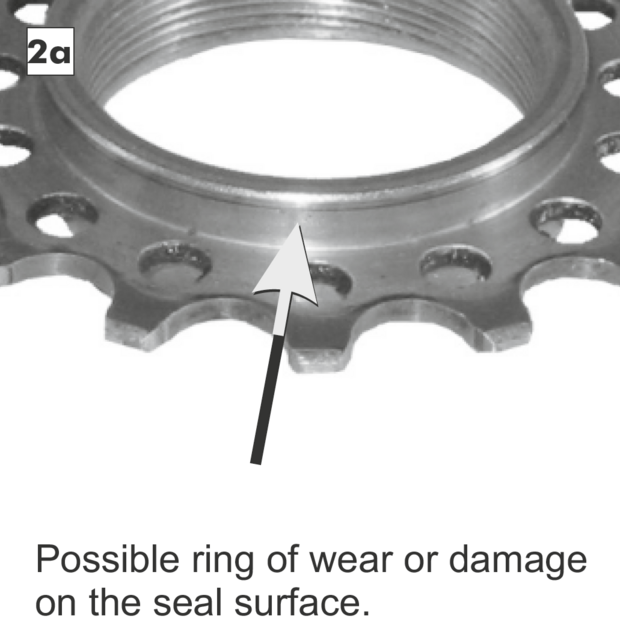

The sprocket sizes 15, 16 and 17 of the Rohloff SPEEDHUB 500/14 are symmetrical and are therefore reversable, when worn on one side.

After reversing the sprocket, fit a new chain. This will now pull on the other, unworn side of the sprocket. Once both sides are worn, the sprocket must be replaced. The 13 tooth sprocket is not reversable, and therefore, must always be replaced once worn.

Video workshop

Sprocket reversing/replacing

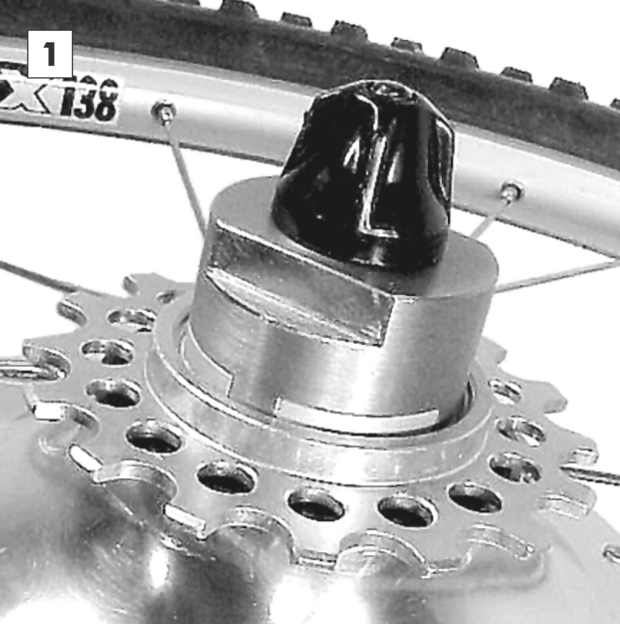

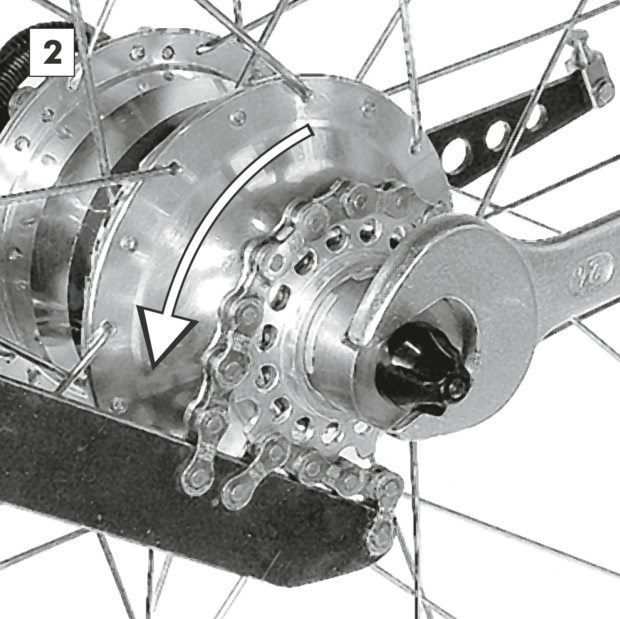

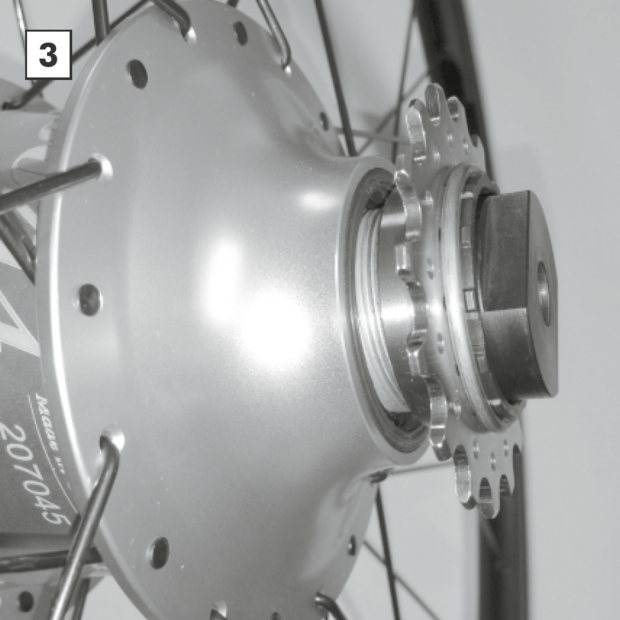

The sprocket can be removed over the sprocket tool. When only reversing the sprocket, clean the sprocket turn it over 180° and screw it back onto the cleaned and regreased thread of the driver in a clockwise direction. Tighten up the sprocket using the chain whip. If the sprocket needs to be replaced, simply screw the new sprocket tightly onto the driver.