Explaining the Model Codes

The first part of the model codes (CC/TS) refers to the axle type. Two different axle types are available:

CC:

Cross Country

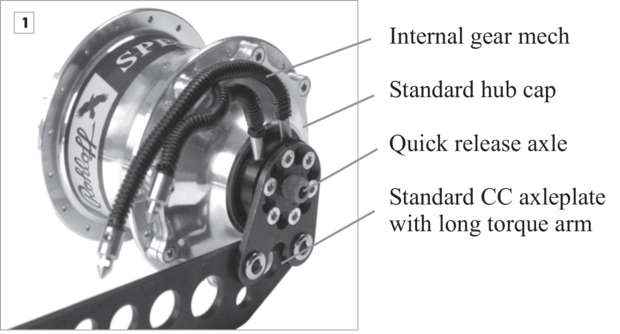

Hollow axle for use with a quick release lever (quick release axle) (axle as shown in pictures 1 and 2*).

TS:

Threaded Spindle axle

Threaded axle with axle nuts M10x1 (axle as shown in picture 3*).

A12:

Thru Axle frame compatible

Secured via 2x M7x1 bolts and special frame reduction sleeves inserted into the 12mm Thru axle dropouts. Dropout thickness test necessary using the special measurement kit - Art.#8600.

The following part of the model codes refers to additional hub specifications:

EX:

External gear mech

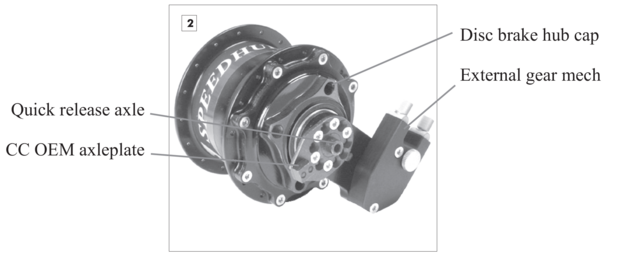

With external gear mech (gear mech as shown in pictures 2 and 3*).

DB:

Disc Brake

With a disc brake hub cap and external gear mech EX (hub cap and gear mech as shown in picture 2*).

OEM:

OEM version (Official Equipped Manufacturer)

With CC OEM or TS OEM axleplate according axle type only for frames with Rohloff OEM dropouts (axleplate as shown in picture 2*).

OEM2:

OEM2 Version

With CC OEM2 or TS OEM2 axleplate according axle type for frames with international standard (IS1999) disc brake mounts (axleplate as shown in picture 3*).

PM:

PostMount version

Axleplate available for both CC and A12 axle types. Anchors the SPEEDHUB torque via a ‘PM Bone’ to the frames direct Postmount brake caliper Mount.

T:

Tandem version

With longer shifter cables (2.5m) for tandem or recumbent use.

XL:

Xtra Large

For frames with a 170/177mm spacing. Only available as a disc brake version finished in anodized black with 32 spoke holes.

XXL:

Xtra Xtra Large

For frames with a 190/197mm spacing. Only available as a disc brake version, finished in anodized black with 32 spoke holes.

All Rohloff SPEEDHUB 500/14 versions are available in three different Colors:

Silver: - anodized (polished aluminum up to 10/2013)

Red: - anodized

Black: - anodized

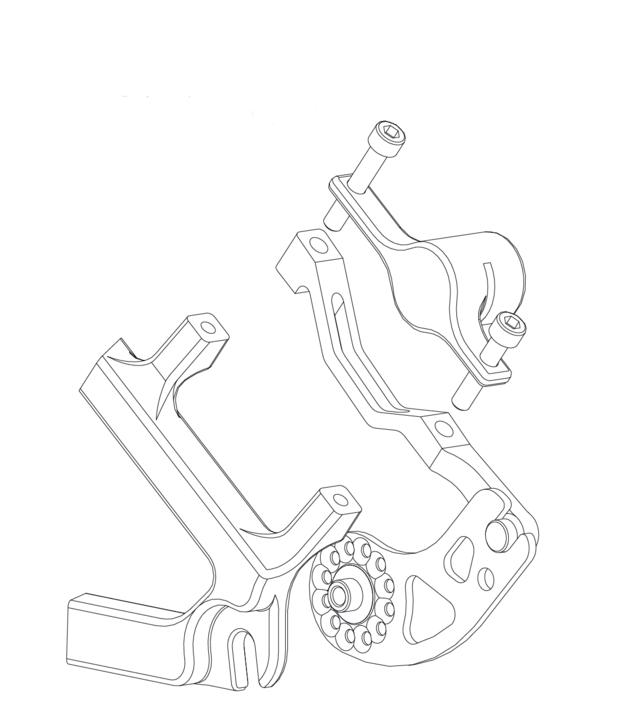

The Rohloff SPEEDHUB 500/14 is available in different versions in accordance to the individual requirements. Pictures 1 to 3 show examples of three possible versions.

Variant for Disc Brake (DB)

The mounting of the Rohloff SPEEDHUB 500/14 with the use of a disc brake requires a frame with disc brake mounts of international standard (Is1999) or Direct Postmount Standard. The hubs are available with the choice of axle, quick release (CC DB versions) or threaded axle (TS DB versions) or with 12mm reuction sleeves and M7 bolts (A12 DB versions).

The particulars of the DB versions are:

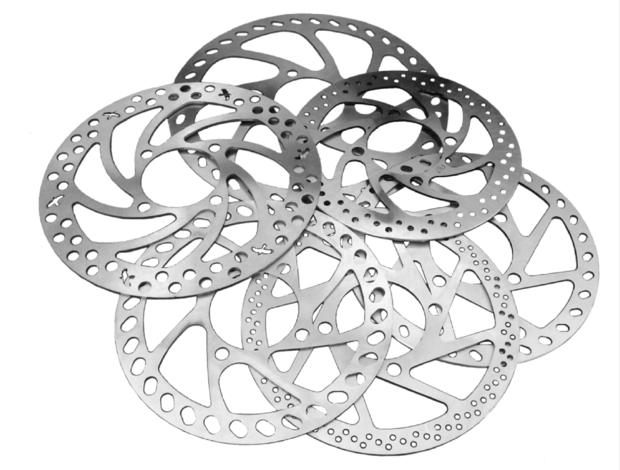

- The hub cap includes a center disc mount. It is on this side that the external gear mech is also to be found. Normal 6bolt brake discs of international standard are not mountable, a special 4-bolt Rohloff disc with only four securing holes for bolts M8x0.75 must be fitted due to the large diameter of the hub seal. Rohloff offers a range of discs from 160mm to 203mm for nearly every type of disc brake currently on the market. More details are to be found on the web under www.rohloff.de > FAQ > SPEEDHUB > disc brake

- The disc brake versions of the Rohloff SPEEDHUB 500/14 are only available with the external gear mech, because the brake disc/caliper could interfere with the hub cables of the internal gear mech.

The interchangable parts system allows the conversion of any Rohloff SPEEDHUB 500/14 to a disc brake version (DB versions). The conversion of a hub to a DB version can only be carried out by the Rohloff service department.

Advantages of the Separate Options

Threaded axle TS:

The Rohloff SPEEDHUB 500/14 versions with a threaded axle are required for frames with horizontal dropout slots. It is, however, also possible to mount this hub in dropouts with vertical slots. For downhill riders the possibility of using a more secure TS threaded axle will increase rear wheel stability much like a thru axle.

Quick release axle CC:

The Rohloff SPEEDHUB 500/14 versions with quick release axles are exclusively for use on frames with vertical dropout slots. They allow for a quick removal/installation of the wheel without the need for Tools.

Thru axle compatible system A12:

The Rohloff SPEEDHUB 500/14 Versions with an A12 axle are specifically designed to fit 12mm thru axle frames. The use of special adapter sleeves (available for DT/Maxle, Syntace, Shimano thru axle styles).enable these SPEEDHUBs to be retrofitted to a great number of current production Frames.

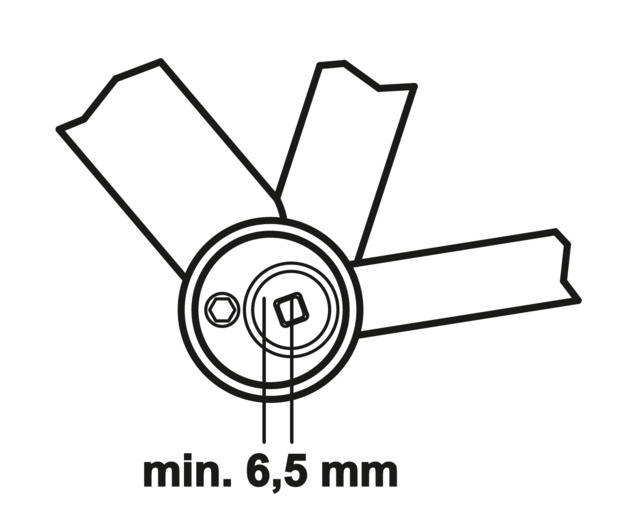

Internal gear mech:

The internal gear mech is on all Rohloff SPEEDHUB 500/14 versions with the exception of EX and DB models. It requires a minimum distance of 240mm between the axle and the cable guide mounting point. To prevent the possibility of the bayonet connectors coming into contact with the brake disc, a combination of disc brake and internal gear mech is not available. The internal gear mech model is the lightest of the two gear mech versions with the Rohloff SPEEDHUB 500/14 CC weighing approx. 1700g.

External gear mech EX:

The models with an external gear mech allow the shifter cables to run uninterrupted from the twist shifter to the cable box, so the need for a separate cable stop is also eliminated. Because of this, the external gear mech is especially useful for frames with a short chainstay length (20" wheels) or uncommon rear triangles. The external gear mech is approx. 100g heavier than the internal gear mech, but, therefore, more robust as no separate hub cables are in use. Should a shift cable should break, this system allows the user to select any gear from the outside of the external transfer box making this especially useful for the everyday and the touring rider. The disc brake versions (DB) of the Rohloff SPEEDHUB 500/14 are equipped with the external gear mech as the hub cables of the internal gear mech would come into contact with the brake disc.

OEM:

The Rohloff SPEEDHUB 500/14 OEM versions require the use of Rohloff OEM dropouts where the left hand dropout slot is elongated to house the support block of the OEM axle plate. Hardtail frames with adjustable Rohloff OEM dropouts, eliminate the need for a chain tensioner and chain guide thus offering a cleaner, tidier aesthetic and a higher level of functional safety, ideal for extreme riding situations.

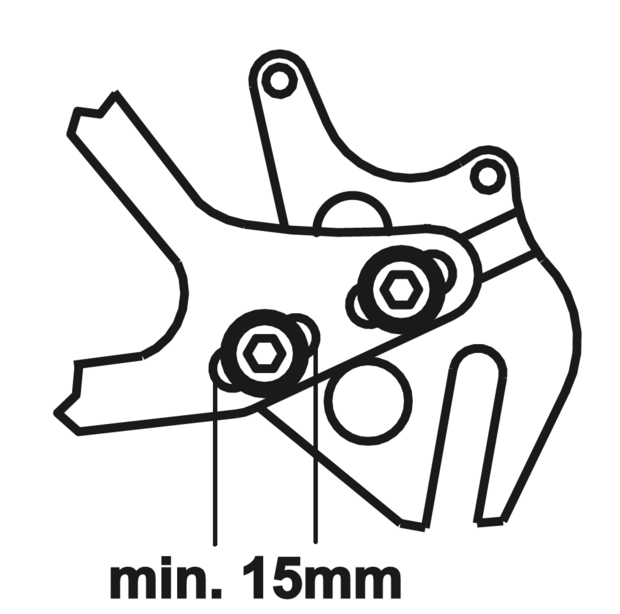

OEM2:

The OEM2 axleplate uses the frames lower disc brake mounting hole to prevent the axle from turning (torque anchor). The OEM2 axleplate offers a cleaner, tidier aesthetic to the system. Only compatible with international standard (IS 1999) mount or when a specially drilled hole is present. An OEM2 axleplate uses the disc brake Mount to secue the torque of the hub. Therefore, permission must be obtained from the frame manufactor to consure directly that frame warranty is not affected.

PM:

The use of a PM axleplate in combination with a PM Bone enables the SPEEDHUB 500/14 models to be retrofitted to frames with an integrated Postmount brake mount. The SPEEDHUB torque is anchored to the frame directly via the brake mount.

XL/XXL:

XL versions are specially lengthened hubs designed for frames with a 170/177mm (XXL = 190/197mm spacing). These hubs enable fatbikes the opportunity to run a strong, symmetrically laced SPEEDHUB with the fattest tires available. XL Versions (CC/TS/A12) are only available as disc brake versions with 32 spoke holes, finished in anodized black. XXL Versions (CC/A12) are only available as disc brake versions with 32 spoke holes, finished in anodized black.

Model Variations

For a better summary of what comes with each model, below is a list of the model variations and the parts included in the respective package.

Rohloff SPEEDHUB 500/14 CC: (silver Art. #8000, red Art. #8001, black Art. #8002)

Contents: Hub with quick release axle, twist shifter, cables, quick release parts, long torque arm and a chain tensioner.

Rohloff SPEEDHUB 500/14 CC OEM: (silver Art. #8005, red Art. #8006, black Art. #8007)

Contents: Hub with quick release axle, twist shifter, cables and a CC OEM axle plate for torque support.

Rohloff SPEEDHUB 500/14 CC OEM2: (silver Art. #8005Z, red Art. #8006Z, black Art. #8007Z)

Contents: Hub with quick release axle, twist shifter, cables and a CC OEM2 axle plate and screw for torque support.

Rohloff SPEEDHUB 500/14 CC EX: (silver Art. #8010, red Art. #8011, black Art. #8012)

Contents: Hub with quick release axle, twist shifter, cables, quick release parts, external gear mech, CC axle plate with long torque arm and a chain tensioner.

Rohloff SPEEDHUB 500/14 CC EX OEM: (silver Art. #8015, red Art. #8016, black Art. #8017)

Contents: Hub with quick release axle, twist shifter, external gear mech, cables and a CC OEM axle plate for torque Support.

Rohloff SPEEDHUB 500/14 CC EX OEM2: (silver Art. #8015Z, red Art. #8016Z, black Art. #8017Z)

Contents: Hub with quick release axle, twist shifter, external gear mech, cables and a CC OEM2 axle plate and screw for torque Support.

Rohloff SPEEDHUB 500/14 CC DB: (silver Art. #8020, red Art. #8021, black Art. #8022)

Contents: Hub with quick release axle, hub cap with mounting for Rohloff special brake discs (compatible with IS1999), external gear mech, cables, twist shifter, chain tensioner, quick release parts and a CC axle plate with a long torque arm.

Rohloff SPEEDHUB 500/14 CC DB OEM: (silver Art. #8025, red Art. #8026, black Art. #8027)

Contents: Hub with quick release axle, hub cap with mounting for Rohloff special brake discs (compatible with Is1999), external gear mech, cables, twist shifter and a CC OEM axle plate for torque support.

Rohloff SPEEDHUB 500/14 CC DB OEM2: (silver Art. #8025Z, red Art. #8026Z, black Art. #8027Z)

Contents: Hub with quick release axle, hub cap with mounting for Rohloff special brake discs (compatible with Is1999), external gear mech, cables, twist shifter and a CC OEM2 axle plate and screw for torque support.

Rohloff SPEEDHUB 500/14 TS: (silver Art. #8040, red Art. #8041, black Art. #8042)

Contents: Hub with threaded axle, twist shifter, cables and a TS axle plate with long torque arm.

Rohloff SPEEDHUB 500/14 TS OEM: (silver Art. #8045, red Art. #8046, black Art. #8047)

Contents: Hub with threaded axle, twist shifter, cables and a TS OEM axle plate for torque support.

Rohloff SPEEDHUB 500/14 TS OEM2: (silver Art. #8045Z, red Art. #8046Z, black Art. #8047Z)

Contents: Hub with threaded axle, twist shifter, cables and a TS OEM2 axle plate and screw for torque support.

Rohloff SPEEDHUB 500/14 TS EX: (silver Art. #8050, red Art. #8051, black Art. #052)

Contents: Hub with threaded axle, twist shifter, cables, external gear mech and a TS axle plate with long torque arm.

Rohloff SPEEDHUB 500/14 TS EX OEM: (silver Art. #8055, red Art. #8056, black Art. #8057)

Contents: Hub with threaded axle, twist shifter, cables, external gear mech and a TS OEM axle plate for torque support.

Rohloff SPEEDHUB 500/14 TS EX OEM2: (silver Art. #8055Z, red Art. #8056Z, black Art. #8057Z)

Contents: Hub with threaded axle, twist shifter, cables, external gear mech and a TS OEM2 axle plate and screw for torque support.

Rohloff SPEEDHUB 500/14 TS DB: (silver Art. #8060, red Art. #8061, black Art. #8062)

Contents: Hub with threaded axle, hub cap with mounting for Rohloff special brake discs (compatible with IS1999), twist shifter, cables, external gear mech and a TS axle plate with long torque arm.

Rohloff SPEEDHUB 500/14 TS DB OEM: (silver Art. #8065, red Art. #8066, black Art. #8067)

Contents: Hub with threaded axle, hub cap with mounting for Rohloff special brake discs (compatible with IS1999), twist shifter, cables, external gear mech and a TS OEM axle plate for torque Support.

Rohloff SPEEDHUB 500/14 TS DB OEM2: (silver Art. #8065Z, red Art. #8066Z, black Art. #8067Z)

Contents: Hub with threaded axle, hub cap with mounting for Rohloff special brake discs (compatible with IS1999), twist shifter, cables, external gear mech and a TS OEM axle plate for torque Support.

All 135mm, 142mm, 148mm O.L.D. models are available as both 32 & 36-spoke versions and/or tandem versions with cables of 2.5m in length. The 36 spoke versions receive an additional number ‘6’ before the article number. Tandem hubs receive the letter ‘T’ after the article number (e.g. 68025 or 8025T).

Additional parts that can be ordered

CC OEM2 axle plate (Art. #8227)

TS OEM2 axle plate (Art. #8228)

CC PM axleplate (Art. #8225)

Chain tensioner (Art. #8250)

Chain guide CC (Art. #8290)

Rohloff SPEEDBONE (Art. #8550)

Monkey Bone IS-PM Adapter (160mm = Art. #8553 / 180mm = Art. #8554)

PM Bone (Art. #8555)

Sprocket (13 tooth) (Art. #8219)

Sprocket (15 tooth) (Art. #8220)

Sprocket (17 tooth) (Art. #8222)

Splined sprockets: 13t-Art.#8541, 14t-Art.#8542, 15t-Art.#8543, 16t-Art.#8544, 17t-Art.#8545, 18t-Art.#8546, 19t-Art.#8547, 21t-Art.#8549

Downhill-Kit (Art. #8293) consisting of:

DH chain tensioner (Art. #8245)

DH chain guide (Art. #8291)

(also available separately)

Cable guide 0° (straight) type with frame clamp (Art. #8260)

DD spokes (2.0/1.8/2.0mm) spoke bend length 2.9mm for 26"-wheels.

Spokes between 228mm and 244mm in increments of 2mm.

Rohloff special 4-hole brake discs for the corresponding brake type.

Recommendations for Components

Chains:

All 8 (1/2"x3/32") speed and 9 (1/2"x11/128") speed chains are compatible with Rohloff SPEEDHUB 500/14 sprockets. 1/2"x1/8" chains can also be used with all Rohloff SPEEDHUB 500/14 sprockets however although these thicker chains may be slightly stronger, they do not offer any improvement regarding durability or lifespan and are therefore not recommended for use with the Rohloff SPEEDHUB 500/14. In addition, these 1/2"x1/8" chains are incompatible with the Rohloff chain tensioner due to their width. When using a 15 tooth sprocket, it is important to make sure that the chain does not measure more than 8.5mm in height (over the joint), otherwise it is possible that rub/wear marks could appear on the hub shell.

Chain rings:

All derailleur gear chainrings can be used for the Rohloff SPEEDHUB 500/14. It is important to check the concentricity of the mounted chainring when utilizing an eccentric BB or adjustable dropouts so that the tension of the chain is correct in all crank positions.

Cranks (chain line):

The use of thread sprockets 15, 16 or 17 teeth on the Rohloff SPEEDHUB 500/14 require a chain line of approx. 54mm from the frame and Splined Sprocktes with 13-19+21 teeth=57mm center. This needs the use of the outer chainring from triple cranksets such as standard Shimano (Largest chainring: 54mm, middle chainring 47.5mm). The middle and smallest chainrings are usable. After the disassembly of the middle and smallest chainrings, the bolts for securing the largest chainring are now too long, because they are now only securing one chainring to the crank. For this reason the Rohloff SPEEDHUB 500/14 small parts bag includes five chainring spacers to distance the original bolts. For retrofitting with double chainring cranksets, the outer chainring should definitely be used.

Reversibel sprocket with 13, 14, 15, 16, 17, 18, 19 and 21 teeth:

The Rohloff SPEEDHUB 500/14 comes fitted with a 16 tooth sprocket. 13-19 and 21 tooth reversable sprockets are available as alternatives. Hereby, an individual sprocket/chainring combination can be applied (see "Technical data" - "chainrings"). The sprockets are reversable, and therefore, can be used from both drive sides. For sprocket removal, a special Rohloff sprocket removal tool (Art. #8508) is needed. When using a 15 tooth threaded sprocket, it is important to make sure that the chain does not measure more than 8.5mm in height (over the joint), otherwise it is possible that rub/wear marks could appear on the hub Shell.

Sprocket with 13 teeth (Art. #8219):

For the use of the Rohloff SPEEDHUB 500/14 on small wheeled bicycles (e.g. 20" folding bikes and recumbants) the special 13 tooth sprocket is needed. It uses a different chain line (58mm instead of mm) and is not reversable. When using a Rohloff chain tensioner on frames with dropouts thinner than 7mm, the longer chain tensioner mounting bolt (Art. #8255) must be separately ordered. For sprocket removal, a special Rohloff sprocket removal tool (Art. #8501 or Art. 8508 ) is needed.

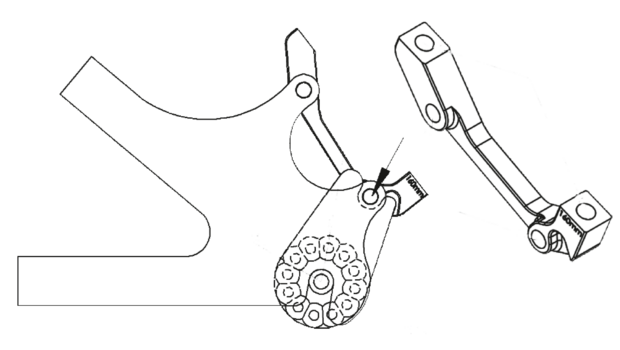

Rohloff chain tensioner (Art. #8250):

Mounting a chain tensioner is necessary on frame types A, C, D, E and G (see "frame types"), because the chain is not tensionable by simply sliding the wheel within the dropouts. The chain tensioner is just as necessary on frames with rear suspension, this is because the distance between the chainring and sprocket varies as the rear suspension is activated. The span capacity of the Rohloff chain tensioner is 10 links or 20 teeth. The use of the Rohloff chain tensioner also requires the use of a chain guide up front.

Rohloff DH chain tensioner (Art. #8245):

The Rohloff DH chain tensioner is specially designed for extreme downhill use. As opposed to the regular Rohloff chain tensioner it has a shorter link arm that is not able to swing on the mounting point. This keeps the chain securely in position against the sprocket, guaranteeing a positive run from the chain onto the sprocket even in extreme riding conditions. The use of the Rohloff DH chain tensioner also requires the use of a chain guide up front.

Rohloff chain guide CC (Art. #8290):

The Rohloff chain guide CC prevents the chain from springing off the chainring on all bikes fitted with a chain tensioner. The Rohloff chain guide is adjustable depending on the chain line (distance between chainring and frame center) between 52mm and 62mm. The chain springing off the chainring in extreme riding conditions is not preventable by a chain tensioner alone.

Rohloff DH chain guide (Art.#8291):

The Rohloff DH chain guide is specially designed for extreme downhill use. It eliminates the chain from falling off the sprocket and onto the hub casing which could happen in extreme riding conditions.

Rims:

The Rohloff SPEEDHUB 500/14 is only available in a 32/36 spoke version. The ideal rims to be used are triple hollow aluminum rims from known manufacturers with reinforced spoke eyelets (min. 4,4mm) or alternatively, rims which are diagonally drilled or with countersunk nipple seats (e.g. ANDRA, Taurus, GRIZZLY and EDGE 7 from Rigida/Ryde or the Ex19 rim from Exal).

Spokes/nipples:

Because the spokes have a large say over the stability of the overall wheel, exclusive quality spokes from well known manufacturers should be used. Double thickness spokes (2,0-1,8-2,0mm) from DT-Swiss and Sapim (with spoke bend length BL 2,9mm) are good examples. When applying a lot of force on the wheel (pannier bags, tandem use, extreme use), the spokes should be fitted with self-locking spoke nipples (lock nipples) during the wheelbuilding process. This reduces the risk of the spokes loosening whilst riding. On rims without reinforced nipple holes, only spoke nipples with rounded heads should be used (Sapim Polymax or DT swiss Prohead), this spreads the spoke tension evenly through the nipple head against the rim.

Quick release lever:

The CC versions of the Rohloff SPEEDHUB 500/14 are supplied with a hollow Q/R axle to secure the hub to the frame. To be sure that the hub is correctly secured into the frame, it is advisable to use a Q/R lever with a steel skewer. The use of lightweight Q/R levers with aluminium or titanium skewers is at the riders own risk! Make sure that the maximum 7Nm closure torque is not exceeded when using a Pitlick or other Q/R systems!

Racing handlebars:

The twist shifter of the Rohloff SPEEDHUB 500/14 can only be used on straight handlebars with a Diameter of 22.2mm and, therefore, is not compatible with regular racing handlebars. Special racing bars (eg racing bars from the firm Norwid (www.norwid.de) or Van Nicholas (www.van-nicholas.com) allow the mounting of the twist shifter. Further information can be found in the FAQs under www.rohloff.de.

Use of a rear disc brake:

The Rohloff SPEEDHUB 500/14 DB versions are equipped with an external gear mech and a special hub cap for the mounting of a brake disc. Only brake discs with a Rohloff mounting hole diameter of 65mm and a center hole diameter of 52mm can be used. Information about the various brake discs currently available can be found on the web under www.rohloff.de. Another alternative is a special seperatable twist shifter for racing handlebars. Gilles Bertoud (www.gillesberthoud.fr) and Co-Motion cycles (www.co-motion.com) both produce such shifters. Further information over this can be found on our homepage in the FAQ section.

Axle plates:

The various axle plates are all available separately, and therefore, making it easy to change any version of the Rohloff SPEEDHUB 500/14 over to a different method of torque support. When a longer axle thread (TS) is required, simply add an “L” to the Art. No.

Axle plate CC (Art. #8232)

Axle plate CC OEM (Art. #8234)

Axle plate CC OEM2 (Art. #8227)

Axlplate CC PM (Art. # 8225)

Axle plate TS (Art. #8233), -long (Art. #8233L)

Axle plate TS OEM (Art. #8235), -long (Art. #8235L)

Axle plate TS OEM2 (Art. #8228), -long (Art. #8228L)

The CC/TS OEM axle plates are also available as stronger tandem versions (T) with only one mounting option.

Rohloff Speedbone (Art. #8550) or IS-PM Adapter MonkeyBone (160mm Art. #8553 / 180mm Art. #8554):

The Rohloff Speedbone is an adapter that allows bikes that are fitted with disc brakes to also use the OEM2 method of torque support. The Rohloff Speedbone is compatible with all disc brake types of international standard (IS 1999). The Speedbone is required when using an IS brake caliper with an IS frame. IS frames using PM brake calipers can use either a Speedbone (Art. #8550) or Monkeybone (160mm - Art.#8553 / 180mm - Art.#8554).

Gear mech:

The external gear mech (Art. #8213) and the internal gear mech (Art. #8572) can be ordered separately. This allows an easy change of the gear mech.

Particulars

Rohloff SPEEDHUB 500/14 on Tandems:

All versions of the Rohloff SPEEDHUB 500/14 are available for tandem use (assuming that the frame spacing is 135mm). The typical coding of a tandem version is the letter “T” (eg CC-T or TS EX-T ). The Rohloff SPEEDHUB 500/14 tandem versions come with shifter cables of 2.5m in length. The number of spoke holes is still 32 or 36 (see wheel stability). For stability reasons the use of double butted DD spokes 2.0/1.8/2.0mm.is recommended.

The correct spoke lengths for 26” wheels are readily availible from Rohloff dealers. Spokes for 28” are available from a number of quality manufacturers (Sapim /DT Swiss):

Small wheels:

Wheels with a smaller diameter than 26” should only use a one cross lacing pattern, because this helps to keep the spoke at the correct angle against the rim. Radial lacing of the Rohloff SPEEDHUB 500/14 is not permitted. The Rohloff SPEEDHUB 500/14 should not be laced into a wheel smaller than 18” in diameter, because, due to the hubs large flange diameter, the spokes would enter the rim at a too accute of an angle.

Halfstep:

Through the use of two chainrings with a size difference of approx. 7% (racing cranksets with 39 and 34 tooth chainrings) the change in gear ratio increases could reduce from 13.6% by approx. half. This additional feature is interesting for road racing applications.

Usage of two chainrings:

In extreme riding conditions, where the use of a greater gear range is necessary, it is possible to use the Rohloff SPEEDHUB 500/14 in conjunction with two chainrings. This increases the number of actual gears by about two. When applying this feature, make sure that there is a difference of approx. 13% between chainring sizes for one additional gear and approx 29% for two additional gears (eg 50/39 chainrings).

Using the Schlumpf/Haberstock “Speed-drive” or the “High Speed drive”:

The Haberstock Schlumpf Speed-drive/High Speed drive works like two chainrings with a large difference in size. With the additional transmisson of 1:1.65 or 1:2.5 the gear ratio of the Rohloff SPEEDHUB 500/14 used in conjunction with the Haberstock/Schlumpf Speed-drive will be increased to 868% or 1315%. It is still important not to undercut the smallest permitted sprocket ratios (see "sprocket ratios").

The Haberstock/Schlumpf Mountain-drive is not permitted for use with the Rohloff SPEEDHUB 500/14.

Using the Rohloff SPEEDHUB 500/14 as an intermediate frame mounted gear-unit:

Should the Rohloff SPEEDHUB 500/14 be mounted within the frame itself, the smallest permitted sprocket ratios from the cranks to the gearbox must not be undercut (see ‘sprocket ratios’). Sprockets used for the transmission from the gearbox to the rear wheel can be of any size.

Using a Bicycle trailer in conjunction with the Rohloff SPEEDHUB 500/14:

The use of a trailer mount in conjunction with the Rohloff SPEEDHUB 500/14 is normally not a problem! However, the problem could arise with different types of trailer models where the long torque arm (when in use) must be carefully adapted. In case of queries please refer back to the manufacturer of the bicycle trailer to find out if they have any experience or special adapters for the mounting in conjunction with the Rohloff SPEEDHUB 500/14. Alternately refer to www.rohloff.de - FAQ > SPEEDHUB > TRAILER.

Using an axle mounted bicycle stand with the Rohloff SPEEDHUB 500/14:

A bicycle stand which is mounted directly on the rear axle of the Rohloff SPEEDHUB 500/14 is available from the company Point bike innovation GmbH, phone 0049 2206 95800. (Bicycle stand Cd93 black, adjustable for 26” - 28”). The SPEEDHUB axleplate “TS long” with the longer thread should be used together with this sort of bicycle stand. www.rohloff.de > FAQ > SPEEDHUB > TORQUE SUPPORT > AXLE PLATES.

Use of an enclosed chainguard:

The chainguard must not rub against the hub shell. This rubbing effect could result in deep brush marks appearing upon the hub shell, possibly eventually wearing completely through it! This damage could lead to accidents through oil leakage or even a complete blockage of the gear unit itself. Sprockets used with on a bicycle fitted with a ‘Hebie Chainglider’ may not be reversed. The Chainglider uses the exposed seal surface to support itself. This use may have caused damage or wear which would lead to excessive oil loss if then rotated and used as a seal surface.

Use of a carbon handlebar in conjunction with the Rohloff shifter:

The Rohloff Shifter (Art. #8200) is not approved for installation on any sort of carbon handlebar. The Rohloff AG will not be held responsible for accidents resulting from the mounting of the Rohloff shifter on carbon handlebars. The Rohloff Shifter (Art. #8206 / 8207) is approved for carbon handelbar use.

Use of Tuning parts:

www.rohloff.de/en/products/speedhub/tuning-parts

Belt drive transmission system ‘Gates Carbondrive’:

When utilizing a bicycle equipped with a ‘Gates Carbondrive’ belt transmission, it is important to adhere to the manufacturers instructions printed within their owners manual. Further information can be obtained from:

www.gates.com/us/en/resources/resource-library/product-catalogs/carbon-drive-technical-manual

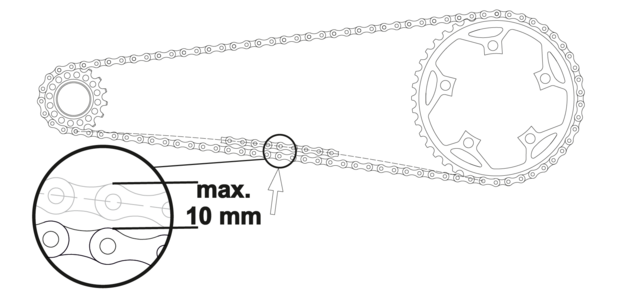

Eccentric BB or adjustable dropouts on frames with the Rohloff SPEEDHUB

It is especially important to use a concentric mounted chainring when utilizing an eccentric BB or adjustable dropouts, otherwise the chain tension could vary extremely. The chain tension should be set so that the chain has approximately 10mm play when lightly pushed from underneath and under no pressure. If using adjustable dropouts in collaboration with the internal gear mech, then it is important to check that there is enough room for the cable adjusters to accomodate the moving of the rear wheel as the chain wears/stretches (if not, the housing may have to be shortened).

Further information over these parts and many others is available on our Homepage under www.rohloff.de/en/service/handbook/documentation