What you can expect to find on this page

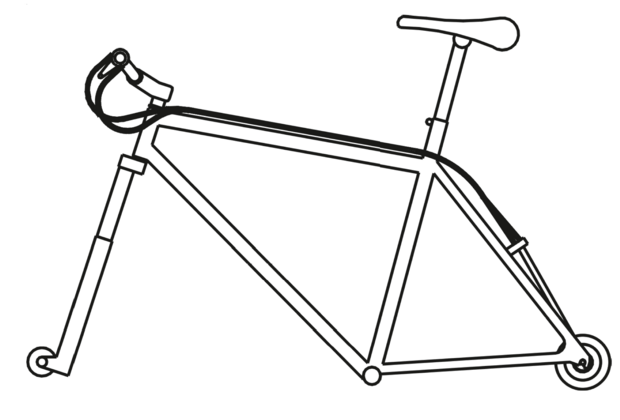

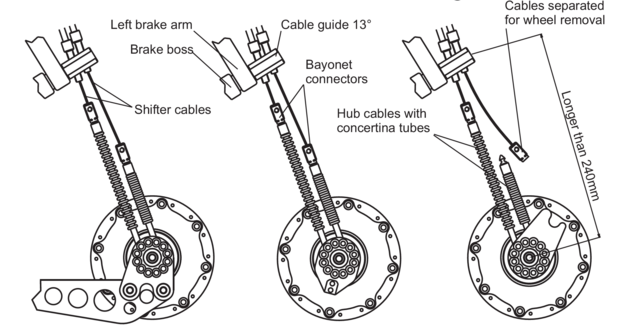

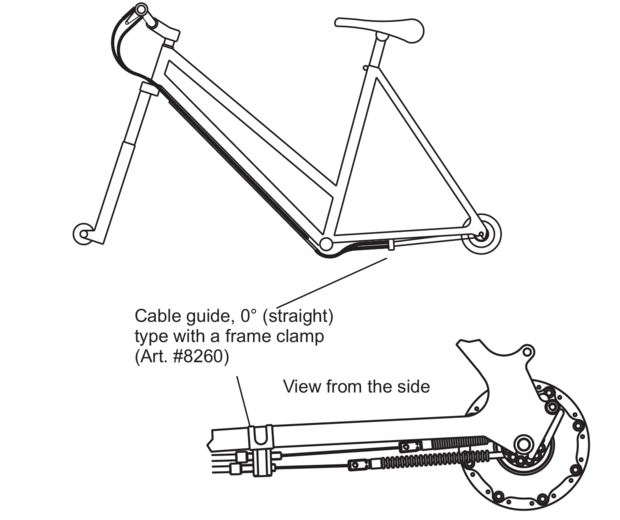

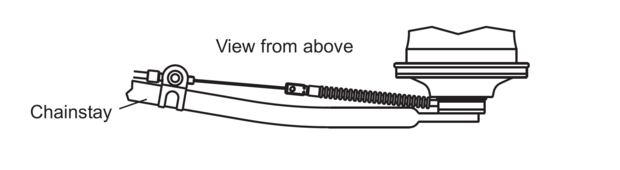

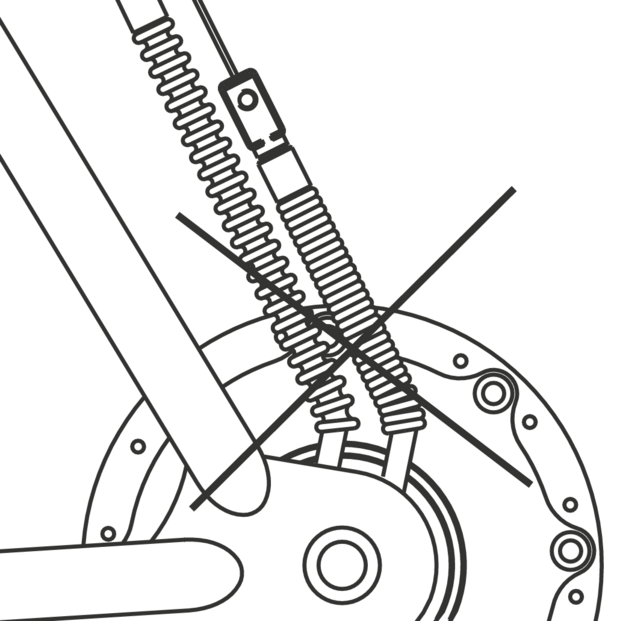

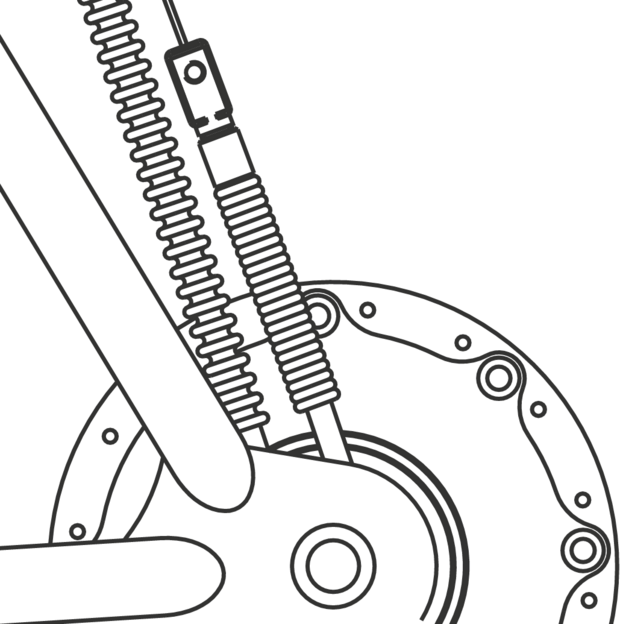

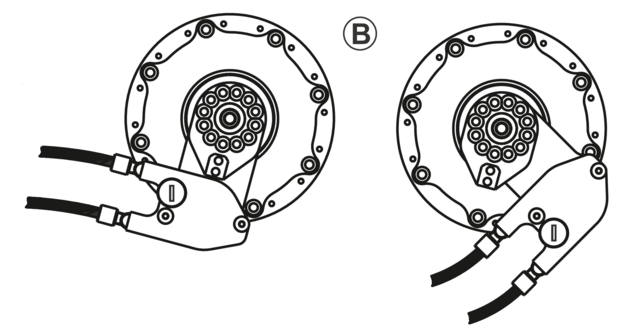

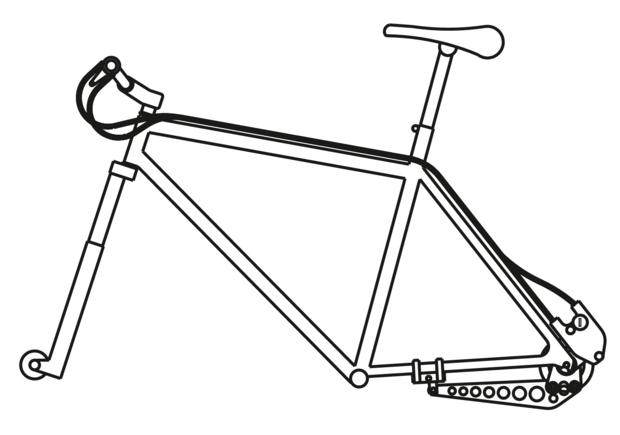

The alignment of the axle plate relies upon how the shifter cables are routed. The axle plate can be rotated in steps of 30° to find the optimum position for cable routing. The following are examples of suitable cable routings.

Of course, it is possible to select an alternative routing. To achive this, however, the axle plate must be aligned accordingly.

Internal gear mech via brake boss

Internal gear mech via chainstay

External gear mech OEM/OEM2

External gear mech with long torque arm

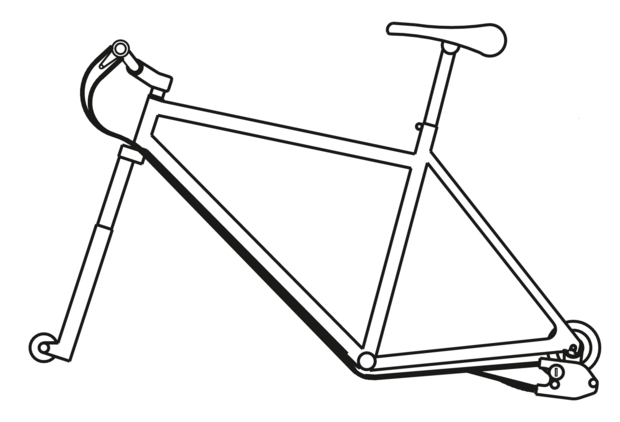

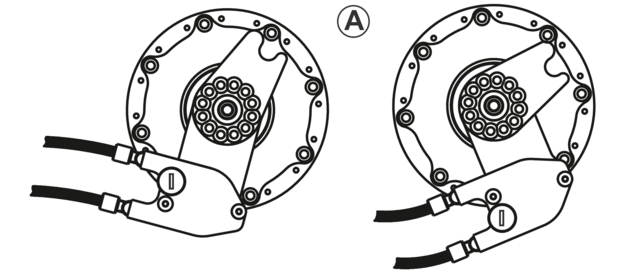

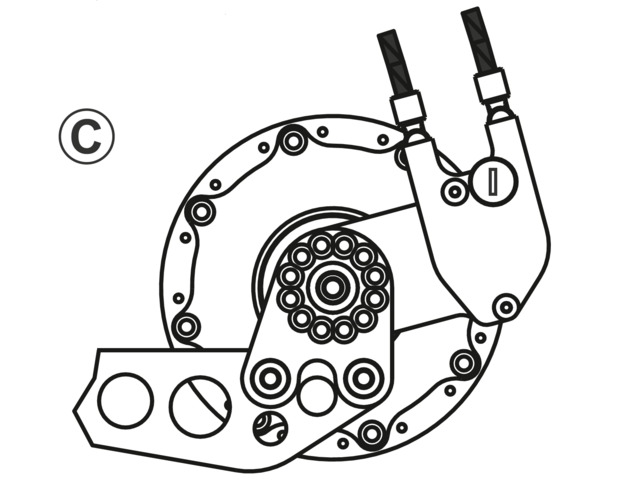

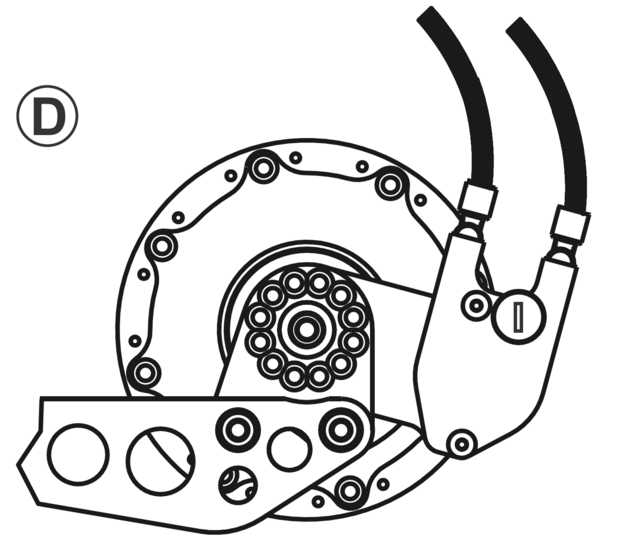

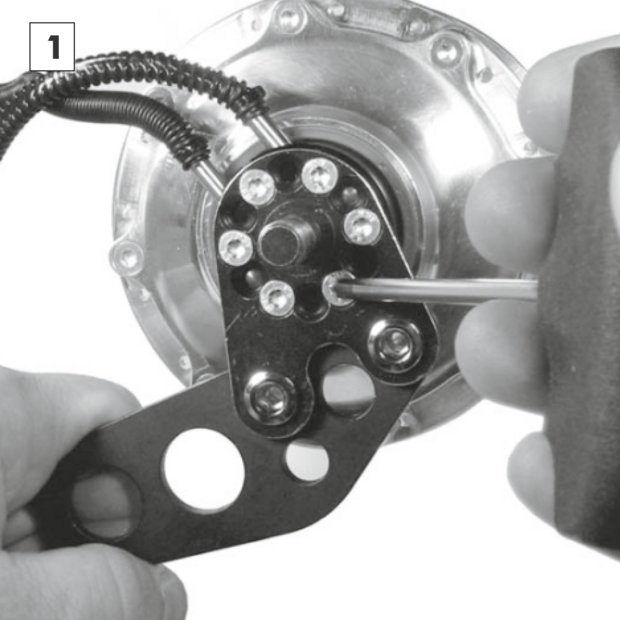

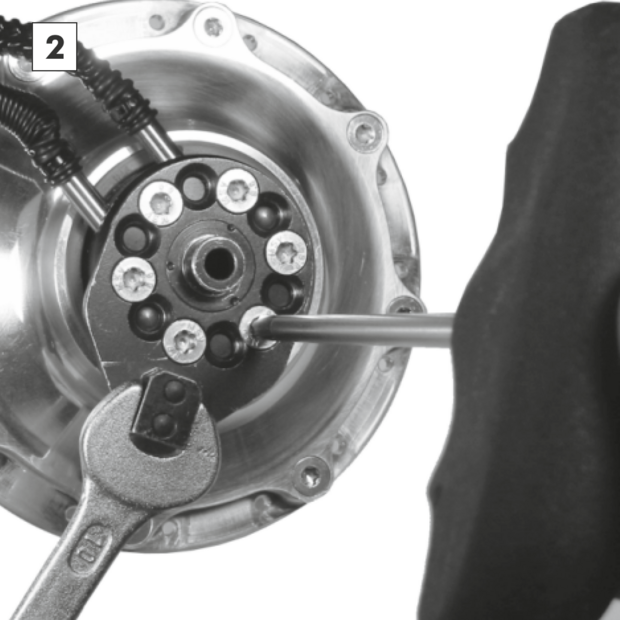

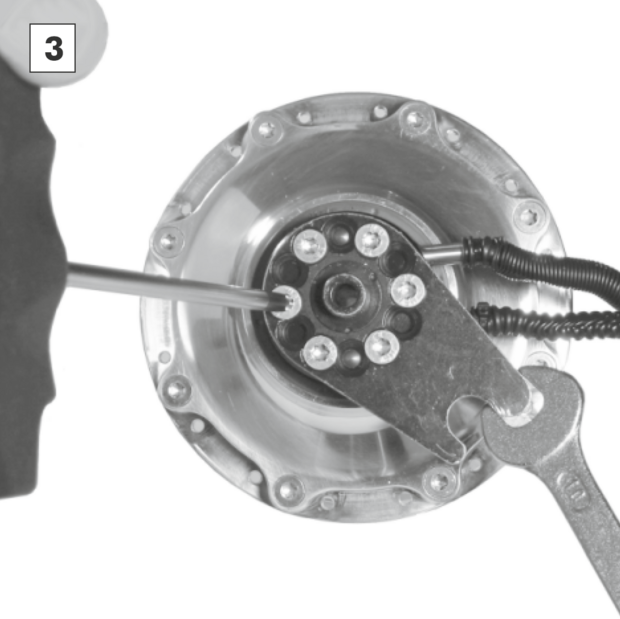

Aligning of the axle plate

To align (rotate) the axle plate, all axle plate screws (M4x25, Torx TX20) must first be removed. Rotate the axle plate into the desired position and then reinsert the axle plate screws through the axle plate into the hub axle. Secure them tightly (tightening torque: 3Nm/25in.lbs.).

To hold the axle in position (when removing the axle plate screws), use a 10mm wrench on the OEM and OEM2 versions or simply hold the long torque arm tightly on the standard axle plate versions (see fig. 1-3 below).