Wheel Stability

32/36 spoke SPEEDHUB wheels are typically far stronger than their derailleur counterparts. The strength is approximately equal a 48 spoke tandem wheel of the same diameter.

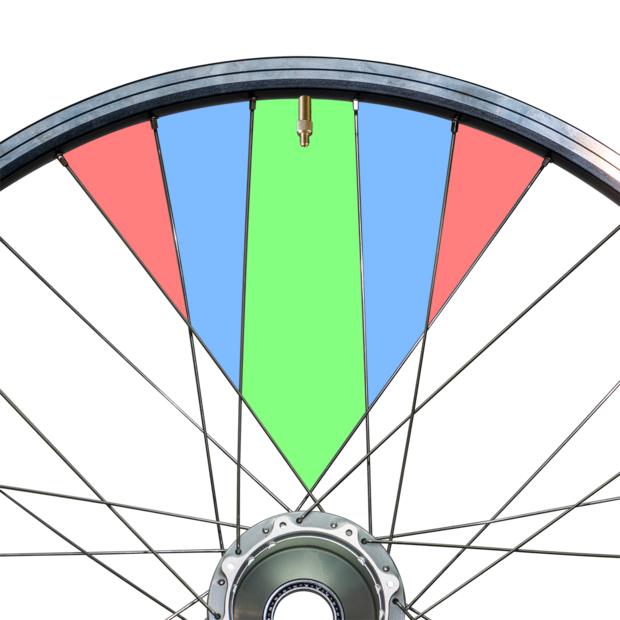

The SPEEDHUB spoke flanges are symmetrically positioned which places the rim directly in the center of the shell. Spokes on both sides of the wheel are therefore the same length and rest at the same angle which enables them to be tensioned equally.

Spoke Choice

Wheel Lacing

Correctly laced SPEEDHUB wheels are more than capable of surviving thousands of kilometers use, through all manner of conditions. It is critical to select the correct materials and follow the instructions carefully, to ensure your wheel is laced as well it possibly can be:

- Never use more than a 2 cross lacing pattern when lacing the wheel

- Ensure flange rings are mounted

- We recommend the use of custom Sapim Race spokes, available directly through Rohloff partners

- Ensure the min. spoke tension is upheld (1000N with air-filled tires)

- Follow the wheel lacing instructions carefully

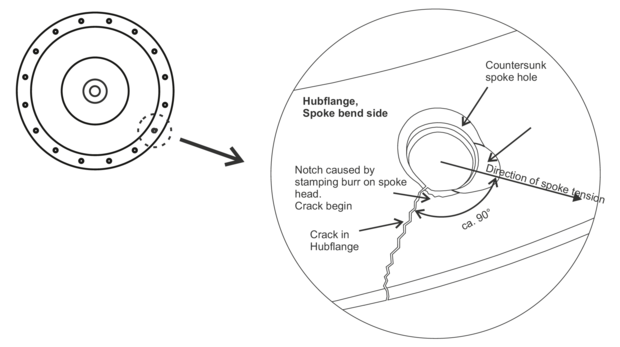

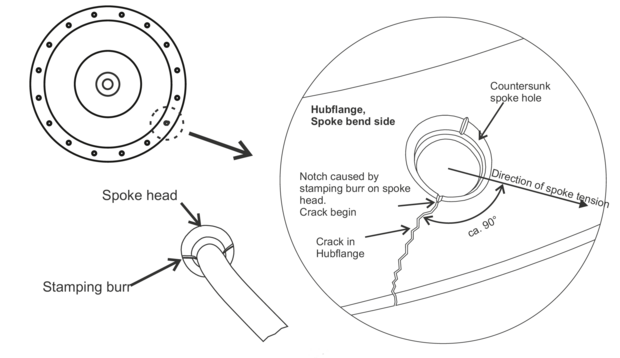

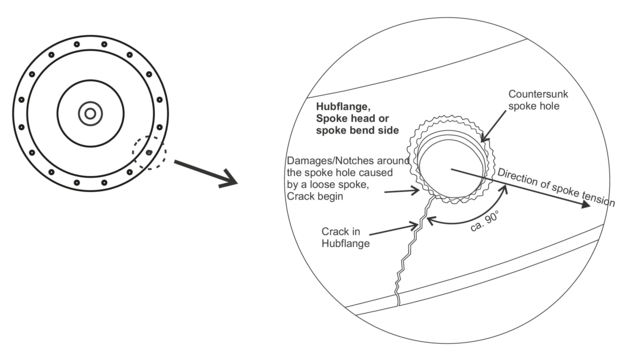

Possible causes for flange breakages on bicycle hubs

Stamping burr on the spoke head

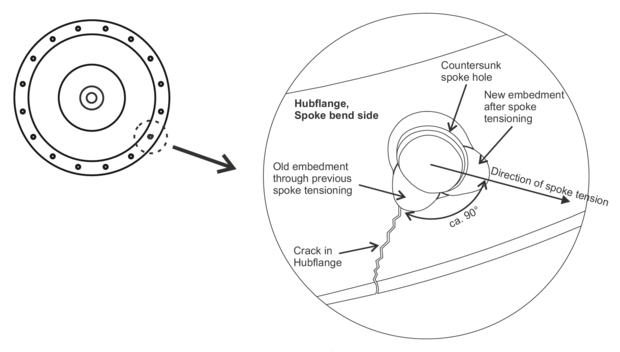

Effect: The stamping burr on the back of each spoke head digs itself into the hub flange leaving a notch at the countersunk spoke hole. If spoke tension then drops below the 1000N requirement, then the burr will act as a saw blade and eventiually cut through the flange material.

Re-lacing with an alternative spoke pattern (second lacing of a used SPEEDHUB)

Effect: The old spoke lacing pattern will have enabled the spokes to embed themselves into the spoke flange, damaging this slightly. If re-lacing in a different pattern, the flange gets damaged again somewhere else. By re-lacing in the exact same pattern, we reduce the number of damaged areas around the spoke hole and thus reduce the chances of the flange failing.