Maintanance Tips

The gears of the Rohloff SPEEDHUB 500/14 are protected from dust and harmful moisture due to running in a oil bath.

The maintenance and care of the Rohloff system is limited to the following points:

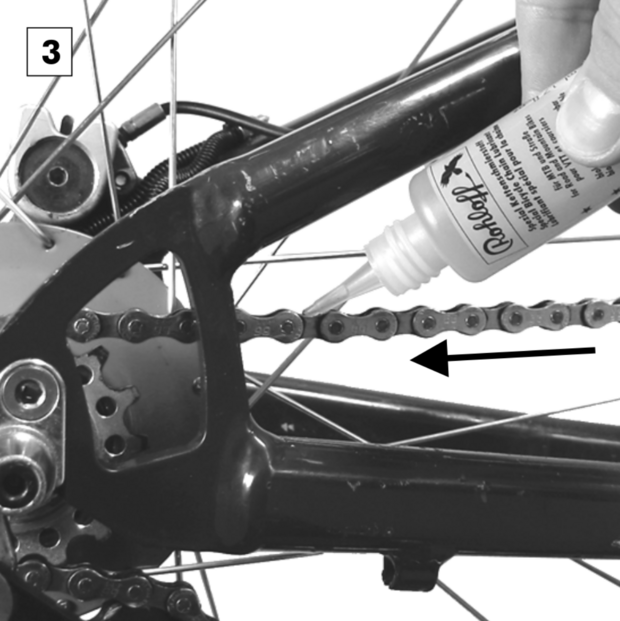

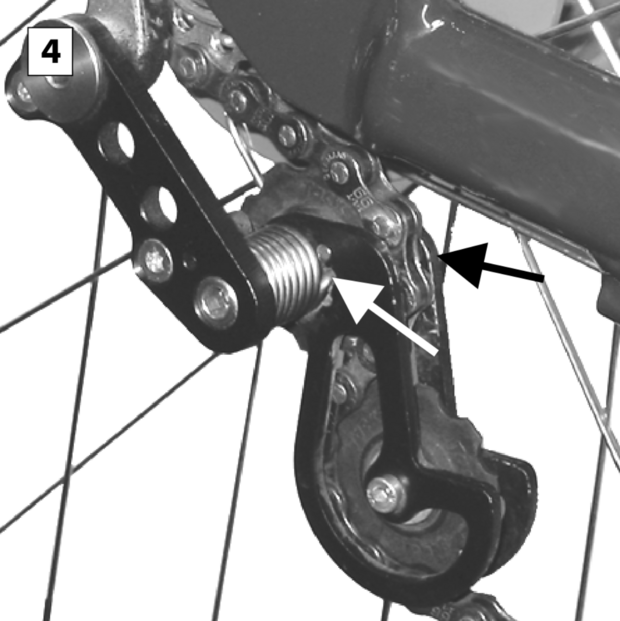

- Chain and chain tensioner (where applicable) should in regard to regular use (at the latest after riding in rain) be cleaned and re-lubricated.

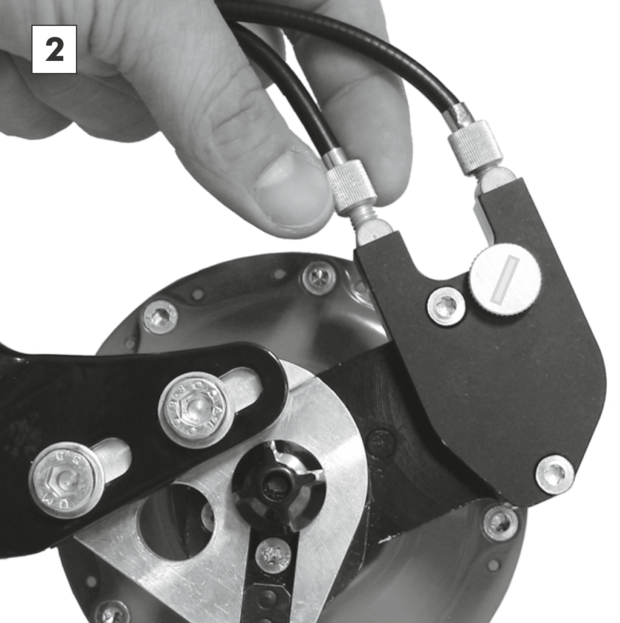

- The cable box of the external gear mech should be demounted approx. every 500km, cleaned and the cable pulley lightly greased from the hub-facing side.

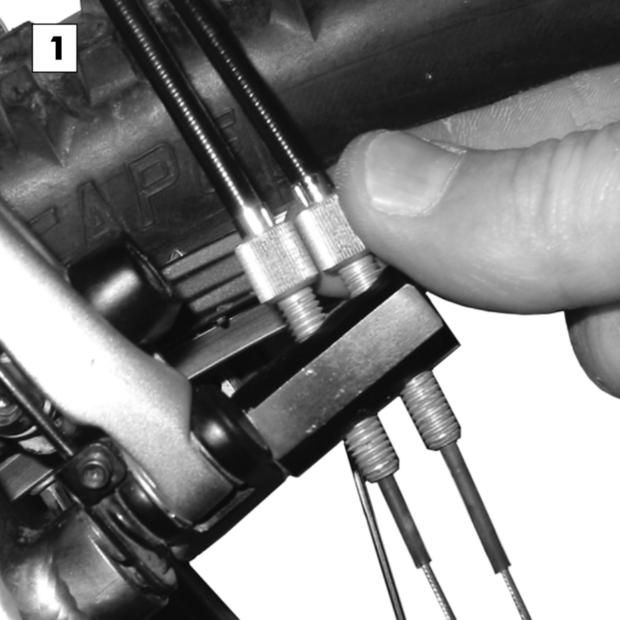

- The shifter cable tension should be regularly checked, and when necessary altered by the cable adjusters.

- The Rohloff shifter cables are made from high-quality stainless steel and run in a nylon lined steel, spiral-wound cable housing which is protected at each end with a sealed ferrule. The cables are routed lubricant free and must not be greased or oiled. The stainless steel/nylon combination runs service-free.

Maintenance and care

The shifter cable tension can be altered by the cable adjusters. Winding the cable adjusters out increases cable tension. For the lightest possible gear change, the tension should be just enough that on the twist shifter there is approx. 5 mm rotational play when in a selected gear.

The mark on the twist shifter body can be aligned to the correct gear number without altering the cable tension by winding one cable adjuster in and the other out.