Have Test Components Ready

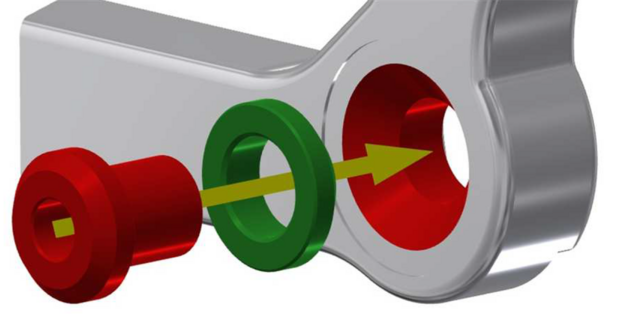

First Measurement Process: Reduction Sleeves

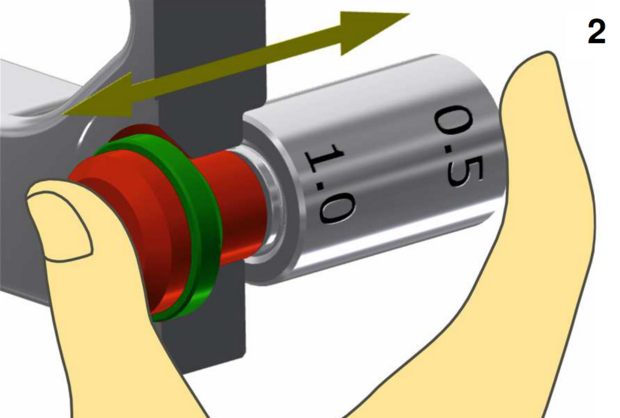

Disc Brake Side (left-hand)

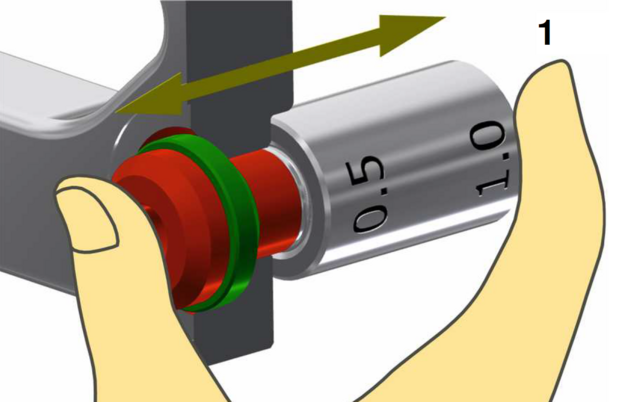

1. Min. Play Test 0.5 mm (Dropout Thickness)

Use the 0.5 mm side of the A12 Dropout Gauge on the back of the left-hand dropout. Use a two-finger wiggle to check whether there is lateral play or not.

Lateral play: Dropout too thin. Go to 1a) Fit Micro Shim.

Zero lateral play: 0.5 mm test result left-hand dropout OK. Proceed to 2) Max. Play Test 1.0 mm.

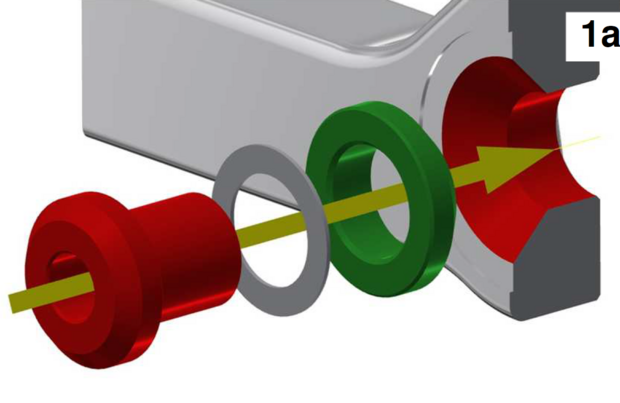

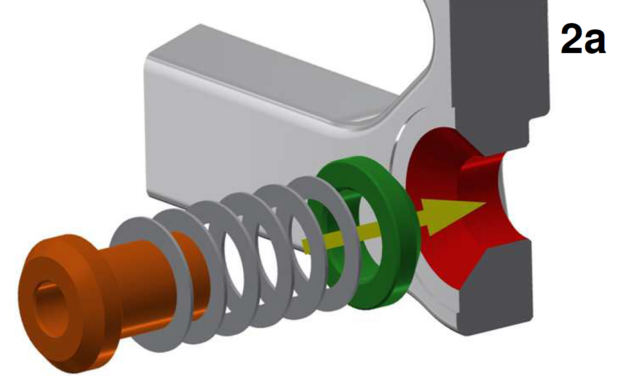

1a. Fit Micro Shim

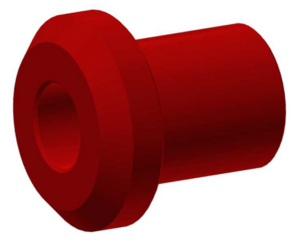

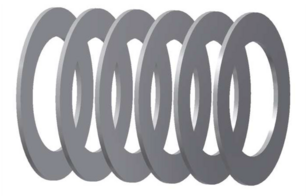

Fit a 0.5 mm micro shim between the A12 reduction sleeve (red) and the spacer (green).

Go to 1b) Check Fit.

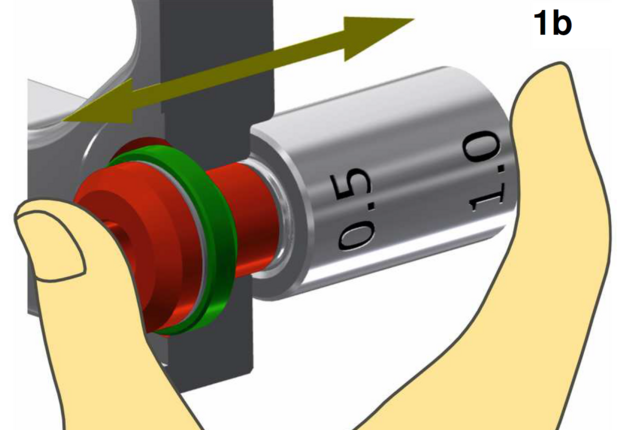

1b. Check Fit

Check whether there is still lateral play or not.

Lateral play: Fit another micro shim and check again.

Zero lateral play: 0.5 mm test result OK. Testing of the left-hand dropout is complete. Max. play test 1.0 not necessary. Note number of required micro shims in the order form. Proceed to 3) Sprocket Side (right-hand).

2. Max. Play Test 1.0 mm (Dropout Thickness)

Use the 1.0 mm side of the A12 Dropout gauge on the back of the left-hand dropout. Check whether there is lateral play or not.

Zero lateral play: Dropout too thick. Go to 2a) Fit Sleeve with Micro Shims.

Lateral play: Test result OK. Testing of the left-hand dropout is complete. Proceed to 3) Sprocket Side (right-hand).

2a. Fit Sleeve with Micro Shims

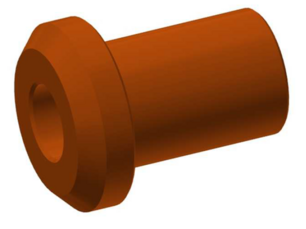

Use extended A12 reduction sleeve (orange).

Fit extended A12 reduction sleeve (orange) with all six 0.5mm micro shims between it and the conical spacer (green).

Go to 2b) Check Fit.

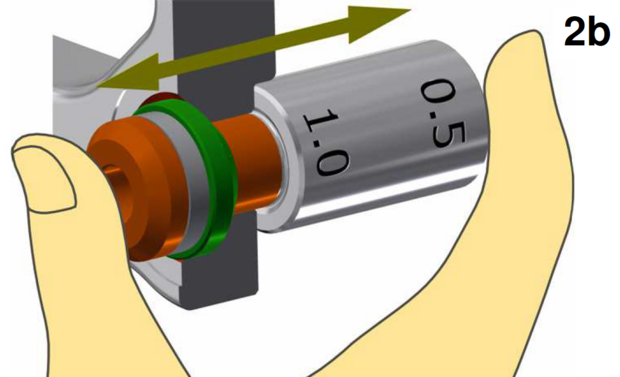

2b. Check Fit

Check whether there is lateral play now or not.

Zero lateral play: Remove one micro shim and repeat the process.

Lateral play: Test result OK. Custom reduction sleeve required. Note number of remaining micro shims on the order form. Proceed to 3) Sprocket Side (right-hand).

Sprocket Side (right-hand)

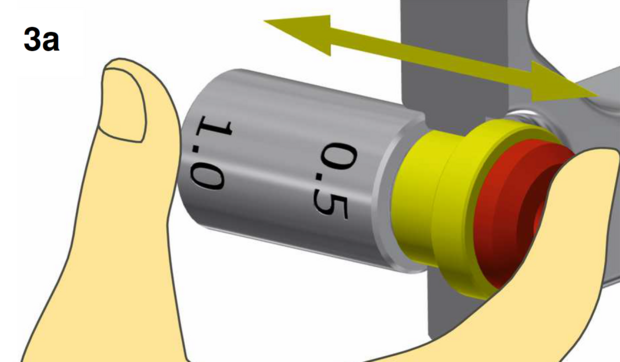

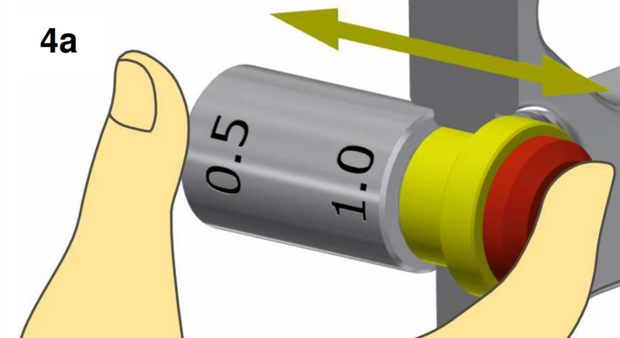

3a. Min. Play Test 0.5 mm (Dropout Thickness)

Use the 0.5 mm side of the A12 Dropout gauge. Check whether there is lateral play now or not.

Lateral play: Dropout too thin. Go to 3b) Fit Micro Shim.

Zero lateral play: 0.5 mm test result OK. Proceed to 4) Max. Play Test 1.0 mm.

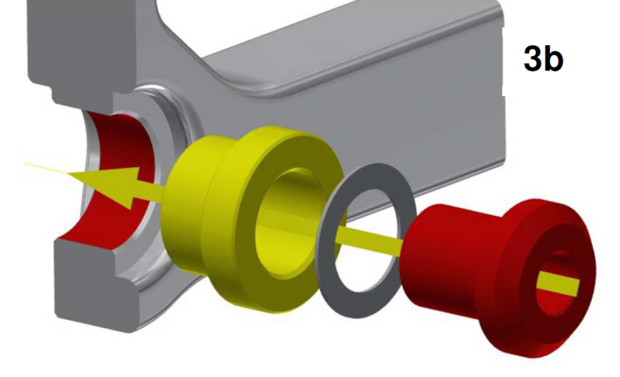

3b. Fit Micro Shim

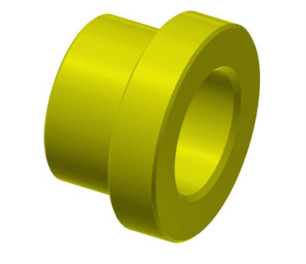

Fit a 0.5 mm micro shim between the A12 reduction sleeve (red) and the spacer (yellow).

Go to 3c) Check Fit.

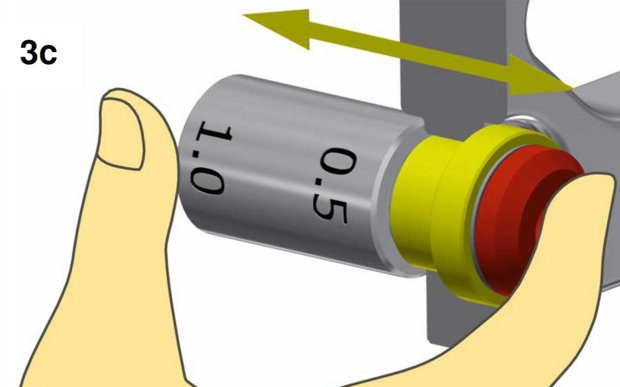

3c. Check Fit

Check whether there is lateral play or not.

Lateral play: Go back to 3b) Fit Micro Shim, fit another micro shim and check again.

Zero lateral play: 0.5mm test result OK. Testing of the right-hand dropout is complete. Max. play test 1.0 not necessary. Note number of required micro shims in the order form. Proceed to second measurement process.

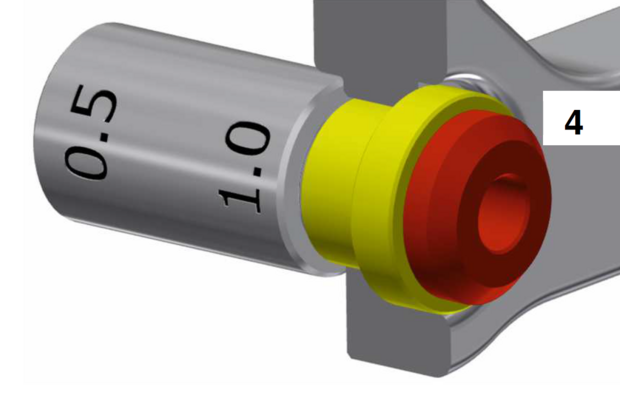

Check by wobbling slightly whether there is lateral play or not.

Zero lateral play: Dropout too thick. Go to 4b) Fit Sleeve with Micro Shims.

Lateral play: Test result OK. Testing of the right-hand dropout is complete. Proceed to second measurement process.

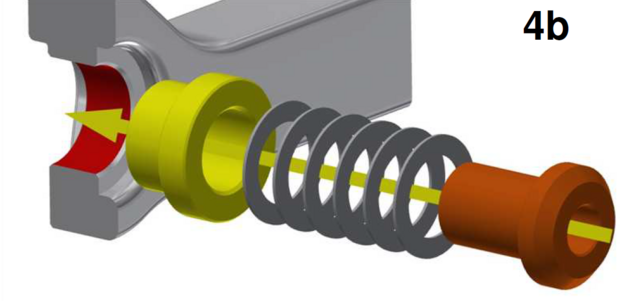

4b. Fit Sleeve with Micro Shims

Use extended A12 reduction sleeve (orange).

Fit extended A12 reduction sleeve (orange) with all six 0.5 mm micro shims between it and the spacer (yellow).

Go to 4c) Check Fit.

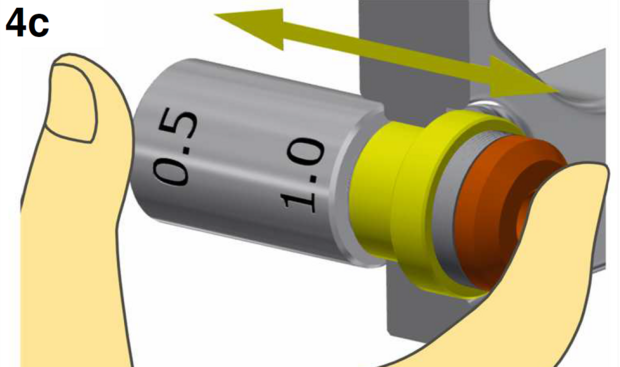

4c. Check Fit

Check whether there is lateral play now or not.

Zero lateral play: Remove one micro shim and repeat the process.

Lateral play: Test result OK. Custom reduction sleeve required. Note number of remaining micro shims on the order form. Testing of the right-hand dropout is complete. Proceed to second measurement process.

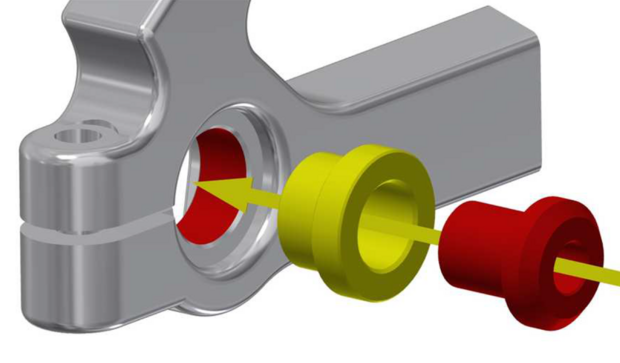

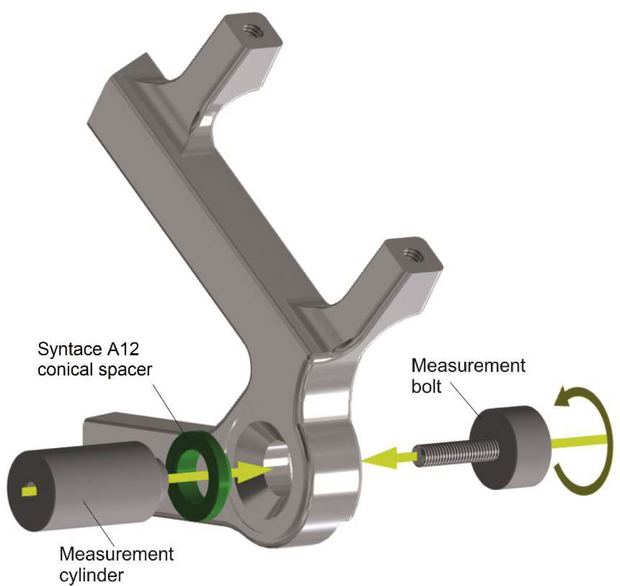

Second Measurement Process: Measurement Gauge

Disc Brake Side (left-hand)

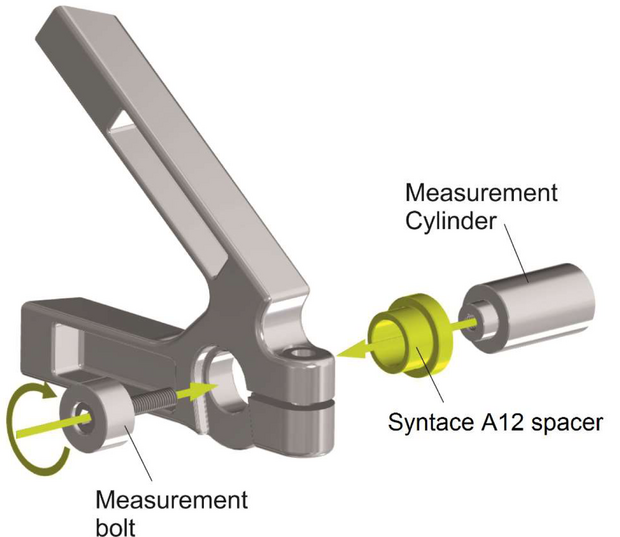

1. Attach Measurement Cylinder and Bolt

Place the Syntace A12 conical spacer (green) over the measurement cylinder.

The measurement cylinder must always be positioned against the outer dropout face. The measurement bolt must always be positioned against the inside dropout face. Press the measurement cylinder (with green conical spacer) against the outer face of the dropout and thread the measurement bolt into it by hand.

2. Take Measurement

Measure the complete length of the mounted measurement tool with a Vernier Caliper as illustrated. Enter the measured value rounded to two decimal places in the order form.

And this is how the result is to be evaluated: If the result of the measurement is less than 51 mm or greater than 57.5 mm, mounting a SPEEDHUB is unfortunately not possible.

Proceed to Sprocket Side (right-hand).

Sprocket Side (right-hand)

2. Take Measurement

Measure the complete length of the mounted measurement tool with a Vernier Caliper as illustrated. Enter the measured value rounded to two decimal places in the order form.

And this is how the result is to be evaluated: If the result of the measurement is less than 51 mm or greater than 57.5 mm, mounting a SPEEDHUB is unfortunately not possible.