Mechanical Efficiency

The mechanical efficiency and consequently the related losses incurred by the Rohloff SPEEDHUB 500/14 are entirely comparable with that of a derailleur system.

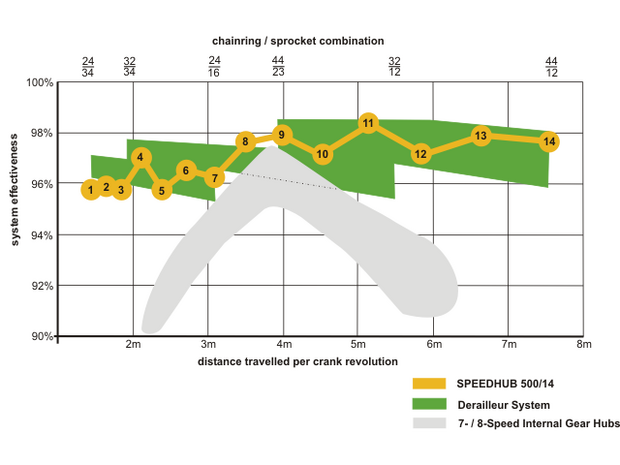

The losses incurred in a derailleur system result from frictional losses generated at the bottom bracket, chain, cassette and hub bearings. The green area within the diagram shows the range of the efficiency of a derailleur system. Depending on the chosen chain ring- sprocket combination, cross chainline and wear situation the losses of efficiency add up to 1.5 - 5%.

The losses incurred with the Rohloff SPEED-HUB 500/14 result from frictional losses generated at the bottom bracket, chain and gearhub. The yellow line shows the efficiency of the Rohloff SPEEDHUB 500/14 relative to the chosen gear. The overall average frictional loss within the Rohloff SPEEDHUB 500/14 ranges between 1.5 - 5%. Consequently, the Rohloff SPEEDHUB 500/14 is the optimum choice for sportive cycling.

As a comparison the grey area in the diagram shows the range of efficiency for 7- and 8-speed internal gear hubs. Characteristical for those is the significant fall of working efficiency in higher and lower gears.