Test Selection

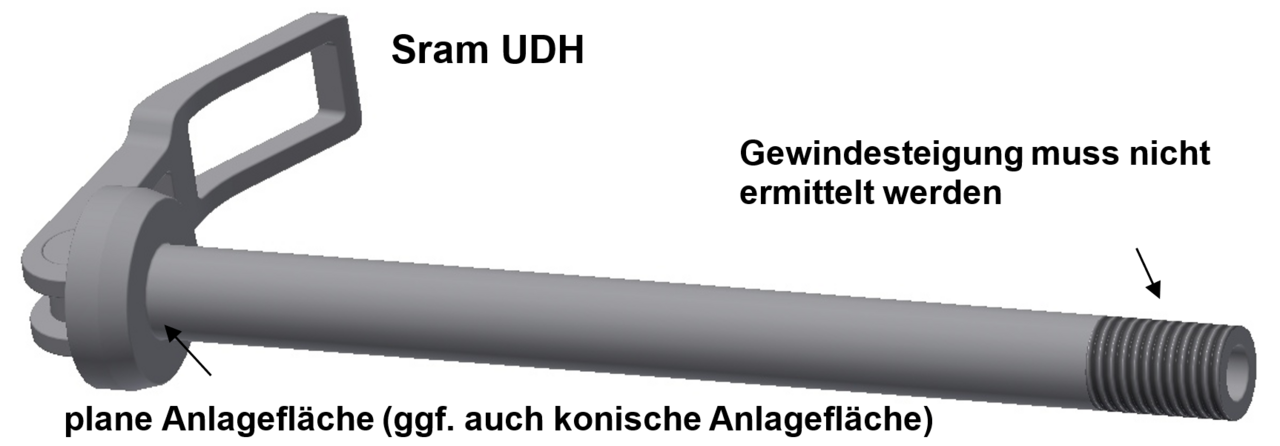

Select your existing thru-axle system to begin the frame compatibility test.

If it is not clear which thru-axle system you are dealing with, you can find out under Determining the Thru Axle.

About the Frame Compatibility Test

The Rohloff A12 SPEEDHUB units are designed to fit into 142mm, 148mm, 177mm and 197mm spaced bicycle frames currently running one of the following 12mm thru axles:

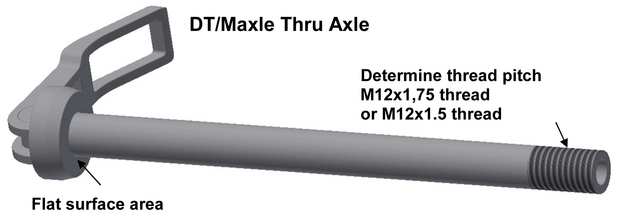

- DT/Maxle

- Shimano e-thru 12

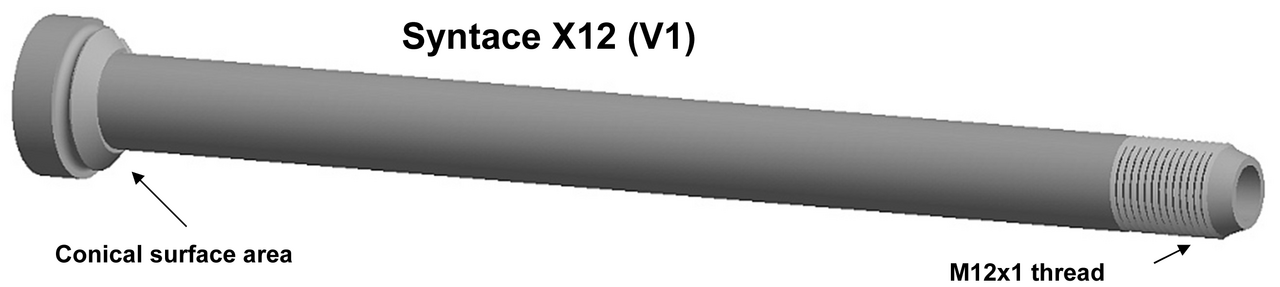

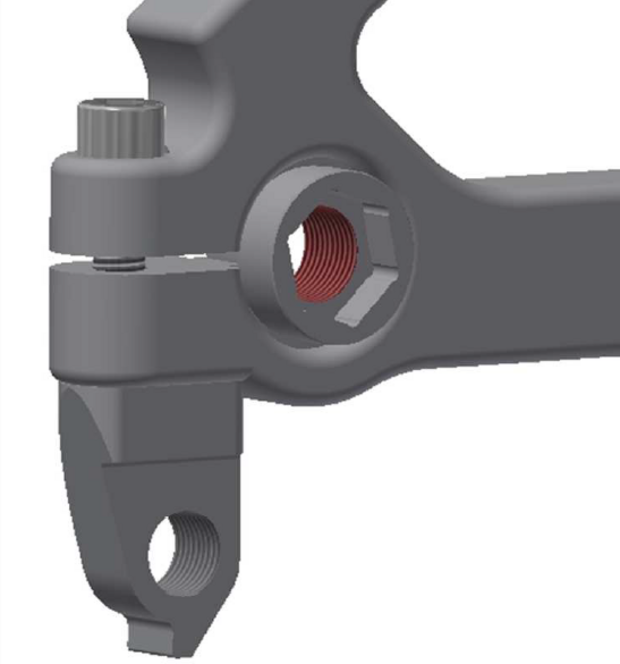

- Syntace X12 (V1): with clamped threaded bush (M12x1) on sprocket side

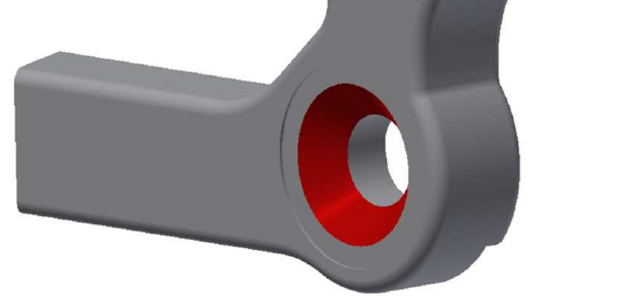

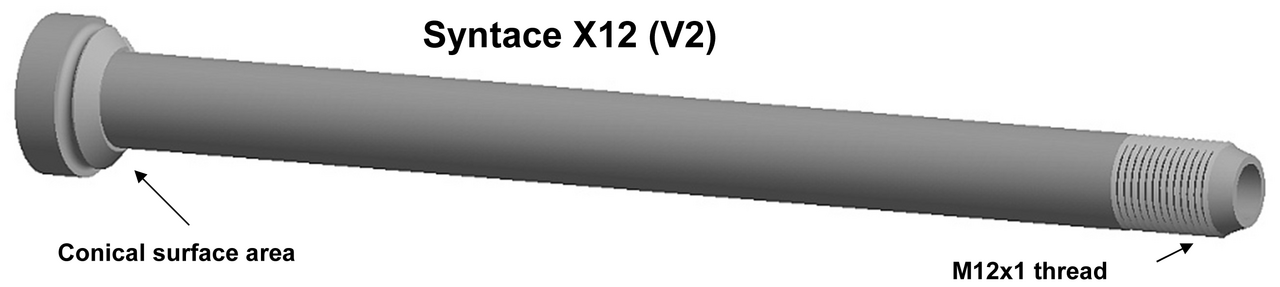

- Syntace X12 (V2): with internal threaded M12x1 sprocket side dropout

Compatibility is determined using the frame compatibility test.

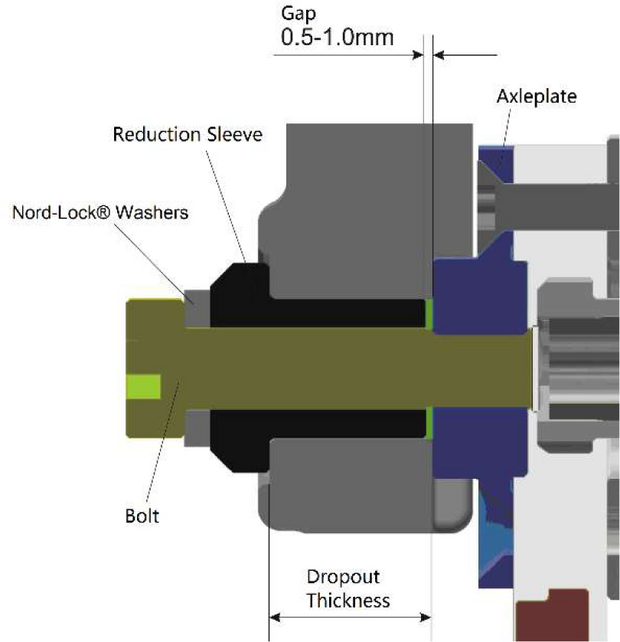

An A12 SPEEDHUB model is only compatible with a bicycle frame when a gap of 0.5mm to 1.0mm is available between the reduction sleeve (black) and the SPEEDHUB axleplate (blue).

The use of micro washers can, to a certain degree, be used to ensure compatibility across a wider range of dropout thicknesses. The dropout test will enable the bicycle mechanic to calculate this.

Only via the correct completion of this test will it be possible to ensure the safe integration of a Rohloff SPEEDHUB A12 model in your frame of choice.

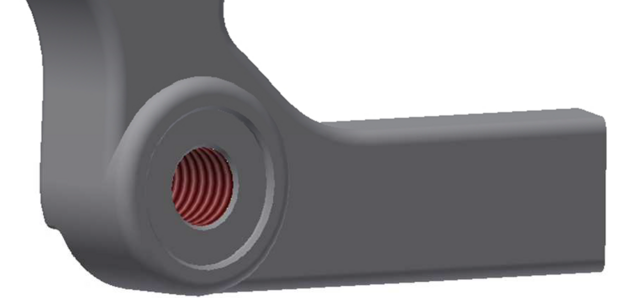

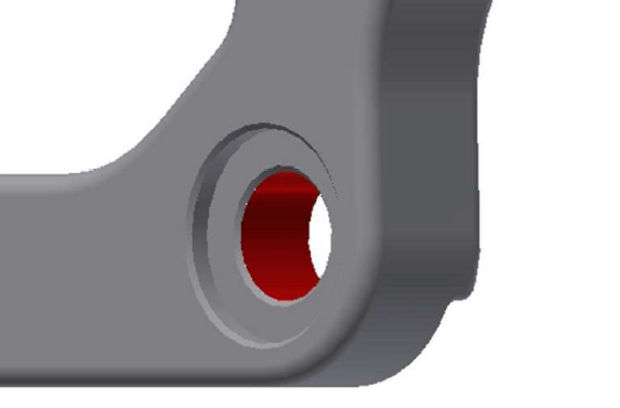

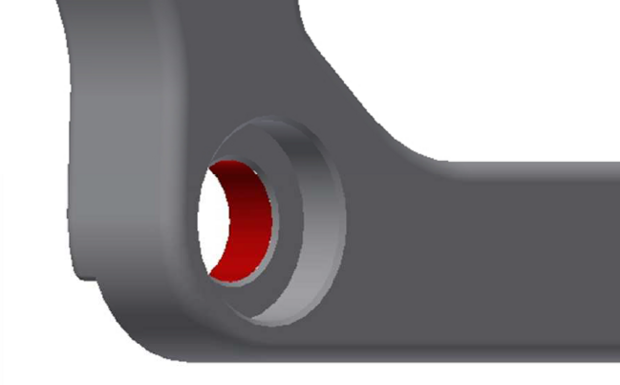

The axle currently used with that particular frame will no longer be required as the Rohloff A12 axle system uses special reduction sleeves to reduce the 12mm diameter axle hole in the dropout to just 7mm.

Specially manufactured M7x1 bolts are then inserted through the reduction sleeves and dropouts and finally threaded into the internally tapped SPEEDHUB A12 axle. To ensure these bolts do not loosen while in use, Nord-lock® washers are additionally added behind each bolt head.

The measurements of the reduction sleeves, bolts and Nord-lock® washers have been carefully selected to offer the largest range of compatibility with the currently available 142mm, 148mm, 177mm and 197mm thru-axle frames.

Alongside the various different axle styles available, the only other variable that may hinder hub/frame compatibility remains the thickness of the dropout material itself. The thickness of the dropout material is not standardised and as such the bicycle mechanic fitting the A12 SPEEDHUB Model will be required to complete a few test procedures to calculate if the A12 SPEEDHUB will fit and if so, what hardware is required.

Possible Measurement Results

The 3 possible issues and their respective consequences are listed below to help illustrate the importance of completing the dropout test carefully.

- Dropout material thickness is compatible with the reduction sleeves = OK.

- Dropout material too thin for the reduction sleeves or bolts. The A12 Rohloff SPEEDHUB versions cannot be secured within the dropouts, the wheel wobbles and leads to accidents and injuries for the cyclist. The bolt screws too far into the axle, clamping the shifting shaft leading to shifting issues and excessive oil loss because of damage.

- Dropout material too thick for the reduction sleeves or bolts. The A12 Rohloff SPEEDHUB versions cannot be secured using enough bolt threads. Bolts will work loose and internal axle threads can be damaged which may lead to accidents and injuries for the cyclist.

Dropout material thickness OK

The dropout material thickness measures between 0.5mm and 1.0mm more than the length of the standard A12 reduction sleeve.

This 0.5mm-1-0mm gap (green) is located between the reduction sleeve (black) and the axleplate (blue).

The bolt (yellow) clamps the reduction sleeve (black) and the axleplate (blue) against the dropout to ensure the SPEEDHUB is safely and securely fastened in position.

The optimum bolt (yellow) insertion depth into the axleplate (blue) is thus achieved.

This optimum depth achieves the maximum thread contact area whilst ensuring adequate clearance (green) between bolt (yellow) and A12 SPEEDHUB shifting shaft (gray).

Only now is it possible to mount the A12 SPEEDHUB model safe and securely within the dropouts of the selected bicycle frame.

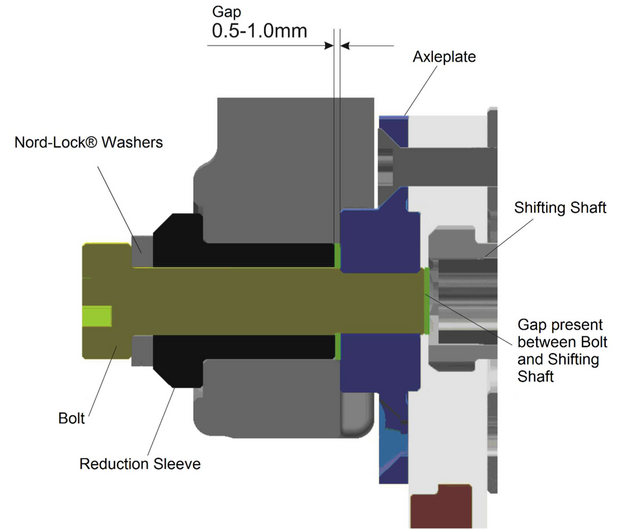

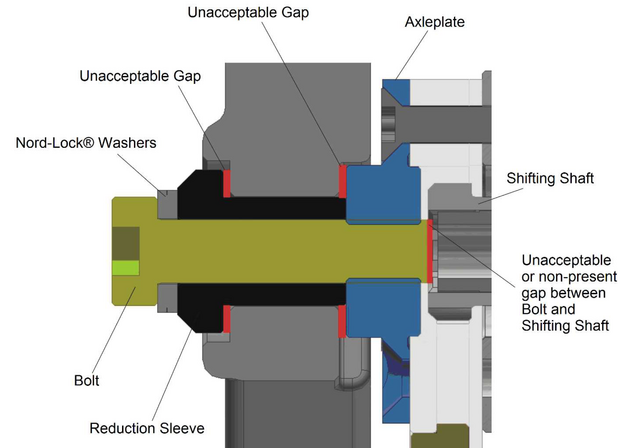

Dropout material thickness is too thin

The dropout material is thinner than the reduction sleeves. A gap has formed between the reduction sleeve (black) and the dropout which cannot be closed. The required gap (red) located between the reduction sleeve (black) and the A12 SPEEEDHUB axleplate (blue) is exceeded. The required gap (red) located between the bolt (yellow) and the A12 SPEEDHUB shifting shaft (gray) is not present.

This results in the bolt (yellow) only being able to clamp the reduction sleeve (black) against the axleplate (blue). The reduction sleeve (black) and Axleplate (blue) are not clamped against the dropout. The ability remains for the entire unit to move laterally within the dropout. The rear wheel is not secured safely in position!

In addition the bolt (yellow) enters the axleplate (blue) too far. The missing gap between bolt (yellow) and A12 SPEEDHUB shifting shaft (gray) is depleted (red). This results in a shifting malfunction (possible complete blockage) within the A12 SPEEDHUB model.

Use of a longer, non OEM bolt will also result in the same issue as written above. It is therefore imperative that only the original, OEM Rohloff supplied bolts are used along with the Nord-Lock® washers supplied.

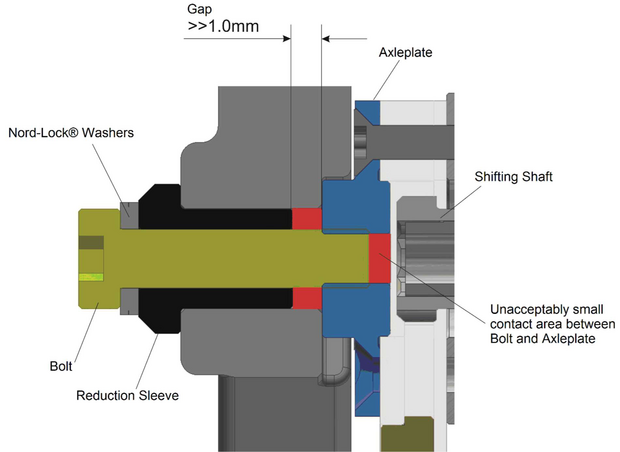

Dropout material is too thick

The dropout material is more than 1mm thicker than the length of the reduction sleeves. A gap (red) of more than 1.0mm is created between the reduction sleeve (black) and the axleplate (blue). The reduction sleeve is unable to support the bolt (yellow) adequately. The bolt may break.

In addition, the contact area between bolt (yellow) and axleplate (blue) is greatly reduced. The forces applied to the bolt in use could, even with the correct tightening torque, cause the thread of the bolt (yellow) or axleplate (blue) to fail. The safe and secure mounting of an A12 SPEEDHUB model is not possible. Bolt or axleplate thread failure can easily lead to accidents resulting in injuries to the cyclist and damage to the SPEEDHUB.

Use of a shorter, non OEM bolt will also result in the same issue as written above. It is therefore imperative that only the original, OEM Rohloff supplied bolts are used along with the Nord-Lock® washers supplied.

Powder Coated Bicycle Frames

Many bicycle frames nowadays are powder coated on both sides of the dropouts. The dropout test can still be completed on frames with thick powder coating.

It is important to check the condition of the powder coating on the dropouts however when using an A12 SPEEDHUB model. Multiple removal and mounting of the SPEEDHUB may cause the thick powder coating to flake. If this occurs, micro shim must be added to compromise for the reduced dropout thickness.

Following an inspection:

The thick powder coating has fully flaked away from the clamp area either on the inner or outer dropout face: Add 1x micro shim to the outside of the dropout must be located between the reduction sleeve and dropout or reduction sleeve and spacer (if applicable).

The thick powder coating has fully flaked away from the clamp area on both the inner and outer dropout face: Add 2x micro shims to the outside of the dropout must be located between the reduction sleeve and dropout or reduction sleeve and spacer (if applicable).